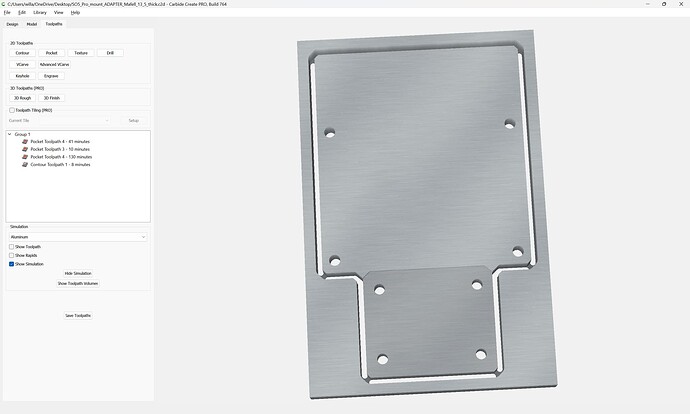

Reworked the mount file a bit:

Modified the file to what I believe is the correct hole spacing for the mounting to the SO5 Pro plate — measure and check against yours before committing:

SO5_Pro_mount_ADAPTER_Mafell_13_5_thick.c2d (608 KB)

EDIT: Note that the above should be slightly shortened at the top, or have a small divot filed into it to accommodate the gas strut if that is also installed.

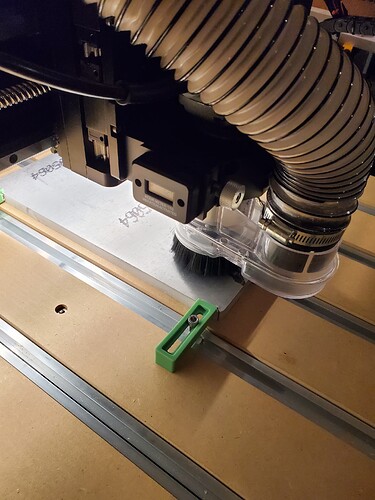

and cutting now: