Ran through the process today, using (mostly) @Randy 's recommendation. After rotating, I set the zero to the middle of the material edge. Then I matched this up with a small hole in the material (so the material was slightly wider than I told meshcam it was). The only problem I really had was that after selecting “lock stock dimensions” … they aren’t locked if you do the rotation. Again, not the end of the world, but kind of inconvenient.

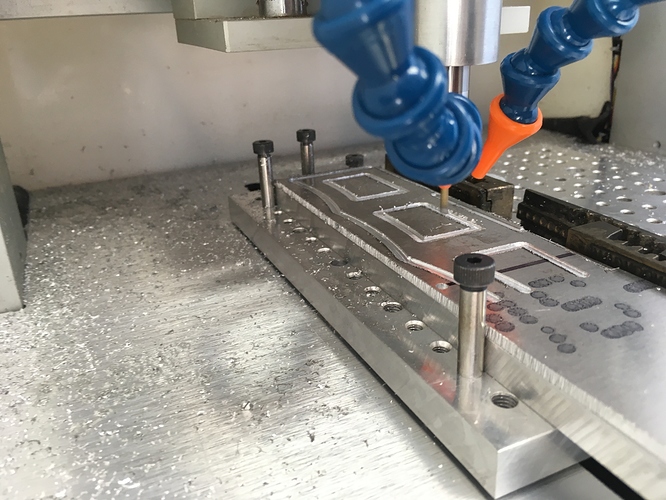

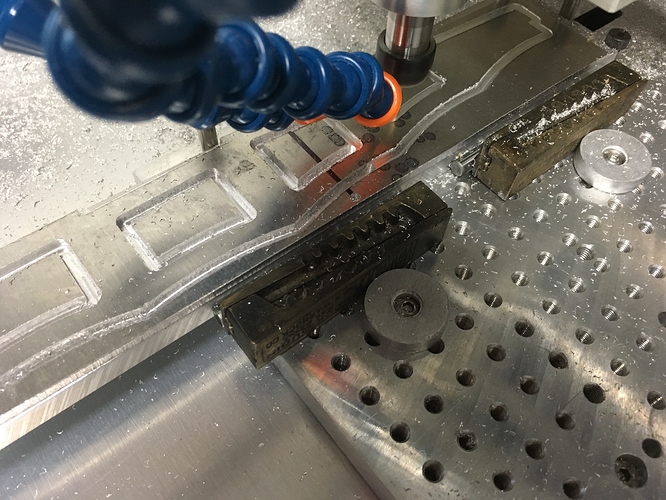

Here’s the setup I used. I made a pallet for the material to be stuck to that has two parallel sides. Once the material is stuck to it you can turn it 180 degrees accurately. Had to get a little creative with the clamping because of a touch of overhang of the material over one side of the pallet. I stuck a dowel pin between the quoins and the side of the pallet, so the material could overhang. Did the same thing when I rotated it. The purpose of the pallet is so there is a set of accurate edges for the rotation, no matter what the raw stock looks like.

Took a couple tries to get things glued down right such that they stayed stuck through the whole milling session… All I can say is to read the directions on the can of super 77…don’t just assume you know what you’re doing…  It’s glue in a spray can. How hard can it be, right?

It’s glue in a spray can. How hard can it be, right?

This particular part is 9.6" long. This method would be good up to ~15" (less than 2x 8").

Here’s cutting the first half. There is an alignment hole (used for zero) in the stock on the left side of the black line. I clearly could have cut further during the this first half.

Here’s the second half. You can see the alignment hole on the right side of the material in this one. This procedure works pretty well, but I need to do something different to pick up the zero, it didn’t come out exactly on where I had wanted it, it’s off my a touch in X (and probably Y). Maybe a pointer and a scribed fiducial next time.