So I did what one should usually not do: ignore @neilferreri’s advice, and proceed with my initial idea  (seriously though, the reason for not going to the Dremel-on-a-custom-jig option is that I want to learn turning small objects anyway, so I invested in something that would be a bit less awkward to use and hopefully more precise)

(seriously though, the reason for not going to the Dremel-on-a-custom-jig option is that I want to learn turning small objects anyway, so I invested in something that would be a bit less awkward to use and hopefully more precise)

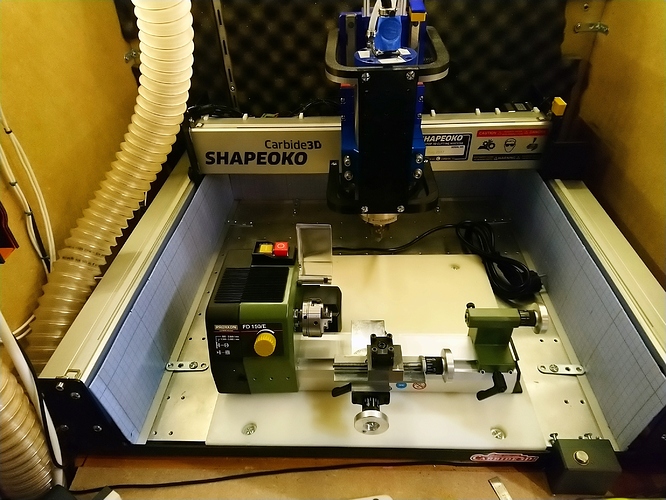

It’s like this mini-lathe and the SO3 were meant to work together.

I’ll update this thread as I progress towards my custom CNC lathe. And then I can rings to rule them all !

By the way, if anyone has advice on good resources/tutorials on turning, I’m all ears.