Hi there,

it’s been a long time, but I have not given up on this project. Minor progress today, which I thought I would share.

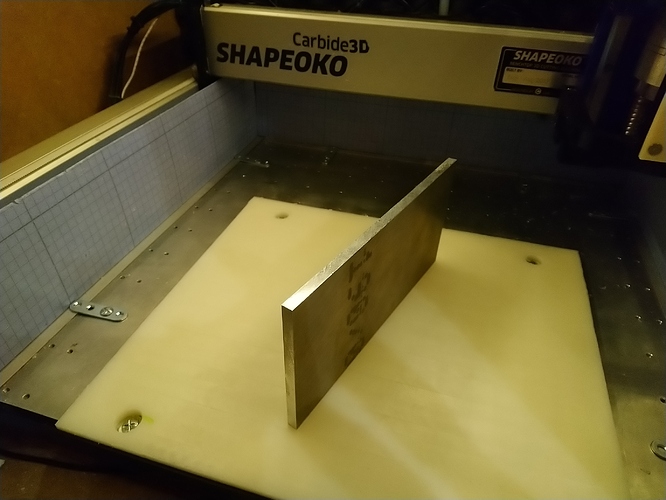

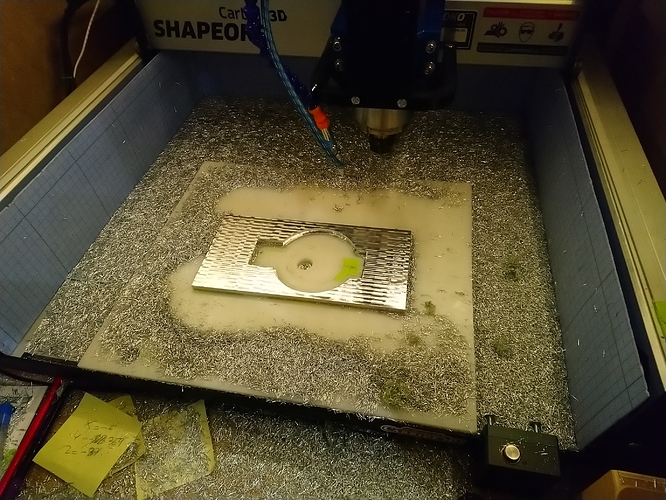

I grabbed this 2017A aluminium plate I had,

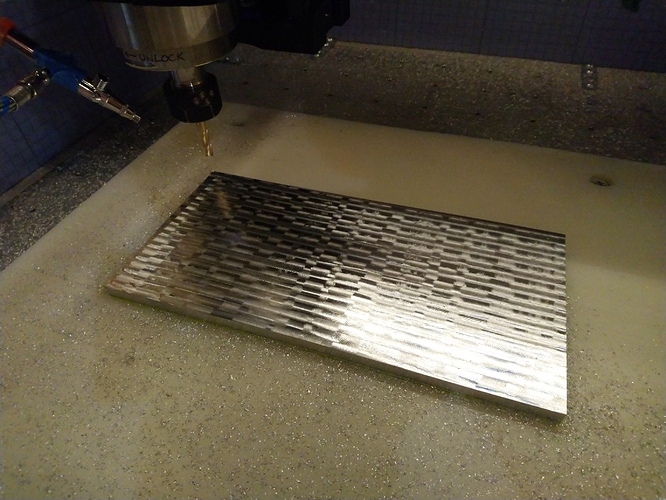

run a little surfacing op,

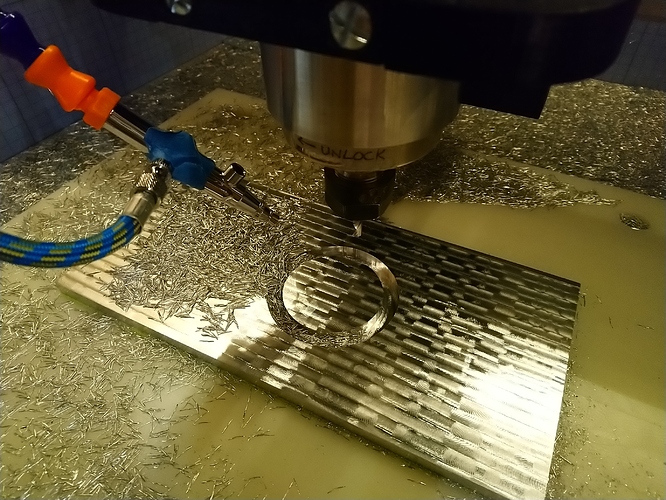

then started cutting,

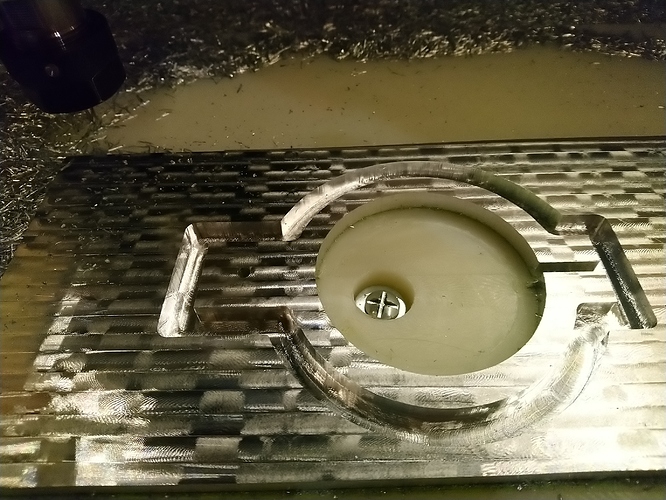

ended up with this,

and a whole lot of chips to clean-up,

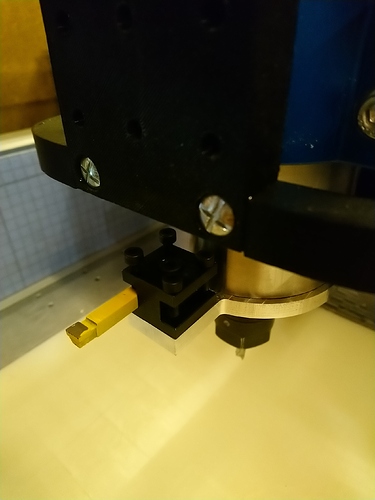

I tapped the front hole (M5), drilled a hole from the side to insert a bolt+nut for tightening the piece…

… around the lip/recessed part at the bottom of my spindle,

(and by that I mean the “dustproof cover” below)

and finally I was able to attach the little turning tool holder that came with my proxxon mini-lathe:

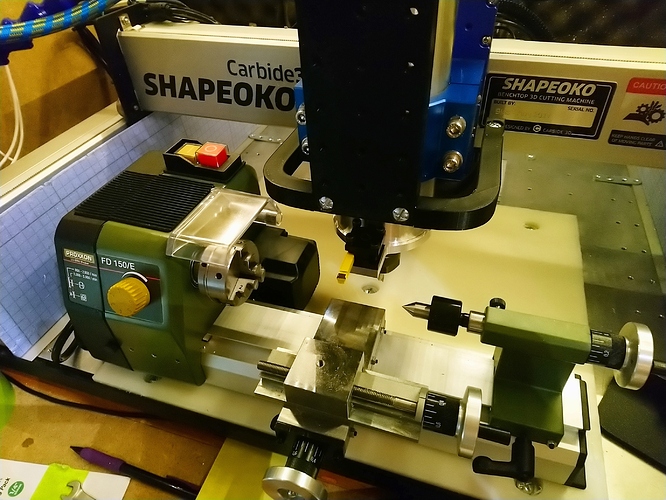

which hopefully should allow me to do this (soon!)

Yes, I have a clearance issue with my 3D-printed frame (usually supports my dust shoe), I’ll have to remove it when turning stuff.

Next on my list: look into attaching the mini-lathe to the aluminium baseboard. And then start looking into generating 2D (XY) toolpath to have the shapeoko move the turning tool. It will either be fun or a total disaster, either way I can’t stop now