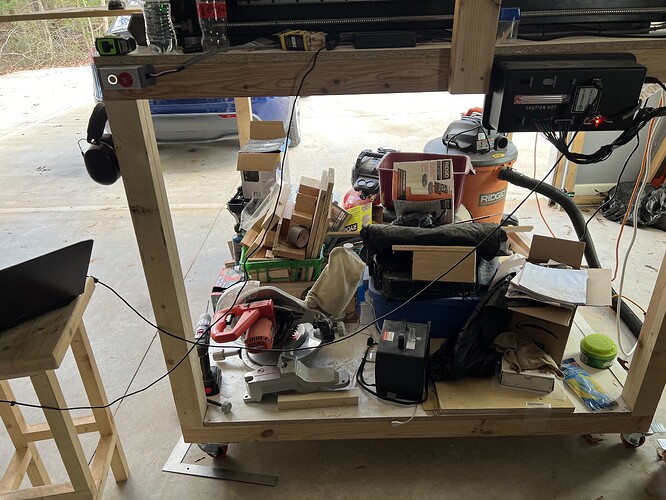

Over the past week I’ve experienced several cases where while my 5 Pro 4x4 lost connection with Motion while carving. How can I determine whether this is due to a blip in my internet or a blip in my power? Or could it be from my control box for my CNC?

Internet doesn’t have anything to do with this — the connection for the computer running Carbide Motion to the machine is via USB.

The big thing to check is the USB cable wiring — is it arranged so that nothing will stress it and any forces on it tend to push the connection into the connector?

Any chance that you may be experiencing a static shock? Maybe from the vacuum hose getting grounded to the frame while it is running (assuming that you do not have a static grounding wire on the hose). I have experienced this on my 3XXL before.

Never thought of that. It’s possible. But wouldn’t it happen more often, if that was the case?

My cheapo thermometer is showing me 10 percent humidity in my shop. My nose is telling me it is right. Even with my grounding, I notice issues when it is like this.

This is what I did to help.

Grounding your Shapeoko - CNC Machines / Shapeoko - Carbide 3D Community Site

- What exact error or behavior did you get?

- Are you running dust collection?

- Is your vacuum hose grounded to the machine?

Rob,

I move from the screen that shows the movement of my CNC, to the No Connection screen asking me to connect to my machine. I’m using a Ridgid 16 gallon shop vac with 20’ hose.

Is the hose grounded to the machine?

Rob,

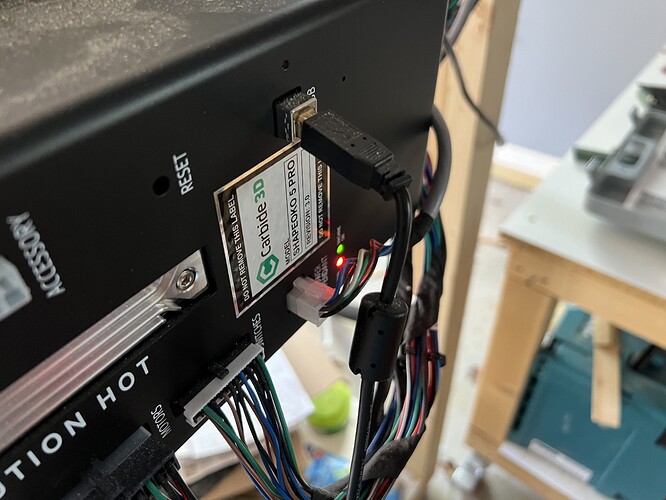

No. Machine is grounded by the plug.![]()

I noticed that it happened when I accidentally touched the hose and the frame of the machine at the same time. I try to avoid that now.

Try grounding the hose to the machine.

I live in East Texas where the humidity is usually 80% or more. However during the northern fronts come through our humidity drops to 30% or so and touching a light switch gives me a static shock.

Depending on what machine you have usually you get a disconnect message if it is static and you have to quit CM to get it to connect again. The SO5 is a different beast so not sure if you have to quit CM to get it to connect again.

My first controller had a loose USB connection. I used a stick back wire tie near the connector to keep it plugged in well. Also check on the laptop/computer side if it seats well and is not loose.

Since you are just getting that you are no longer connected it could be a loose usb connector on either end. The advise about grounding is good and depending on where you live that is a future mine to step on when it gets dry.

So connect your machine and just pull the usb cable out and see if you are getting the exact same message as when you are running. Next time it happens try to get a screen capture of the error message from CM.

Many people don’t realize that a shop vac can produce static electricity from the hose as the vac runs. This can affect electrical plug-ins of delicate machines electronics. Grounding is necessary on machines that will have prolonged use of any vacuum, via; shop vac or dust collection.

If people are reading this thread, this blog post from Rob is worth checking out: Dust Collection and Machine Disconnects

Josh,

Today is a new day. It’s 64 degrees, not 74 like it was yesterday. I ran my CNC in the two conditions given in the link above. SURPRISE!

Nothing happened. So I’m still at square one, and still don’t know what is causing my CM losing connection to my machine. I don’t get any error codes, just the connection screen in CM.

The next time it does happen, I’ll rerun those two conditions right away and see if it does it then.

Connectivity issues with a machine that alarms out or just disconnects usually have issues with the wires. Change out the wires with new wires and see if that works. If the wires are not the issue, then you might have an issue with the port on your motherboard. Looking at your setup and you having the computer sitting on a chair, you might have forced the port by bending the connection and breaking the solder connection. Or check the connection to the control box.

CM would less likely be the reason of your problem of your connection, but its not completely out of the pot of being the issue. If people pull out USB connection ends from computers using the wire to pull them out of the ports, the wire connections inside the plugs tend to break, or the wires break before the solder joints. Then when you plug them in and the connection has issues, you wouldn’t know it without wiggling the wire and causing the connection to break again.

Pulling the connection from your computer and coming back to the cable again another day might not let you repeat the connection issue until you mess with the wires again with moving them.

I have had a similar but not exactly the same on my 5 pro 4x4. It had happened during operations a number of times over about 7 runs, seemingly random occurrences. I set up and ran a part, wiggled all the connections on the wiring harness as it was running and found a connector on the “Z” axis that would trigger the problem when moved juuuuust right.

Ended up replacing the connector and no more problem.

Hope this might help.

Agreed. Any time I have had this issue, it was due to the connection coming a little bit loose.

Thanks for all of the suggestions. I’ll check my wiring, but rest assured that I don’t unplug anything by pulling on the wiring. I grab the plug.