By the way. The ATC has been ordered !!!

Nice! It’s not so easy with GRBL. I’ve always wanted to see a wine rack style tool mount with a gantry actuated cover.

What spindle did you end up going with?

I ordered q Mechatron stc 80. From germany

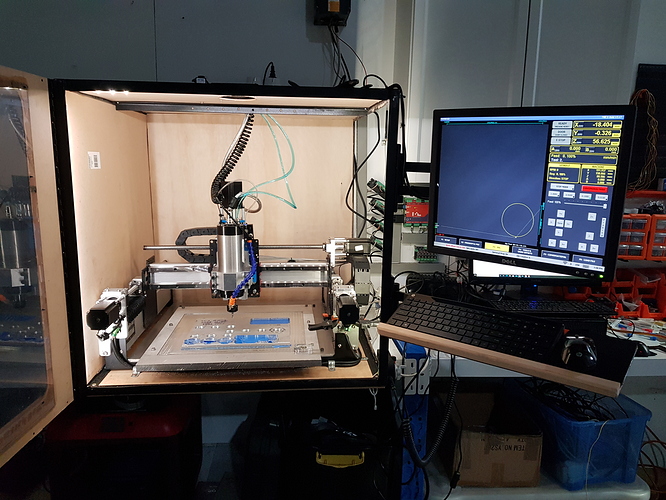

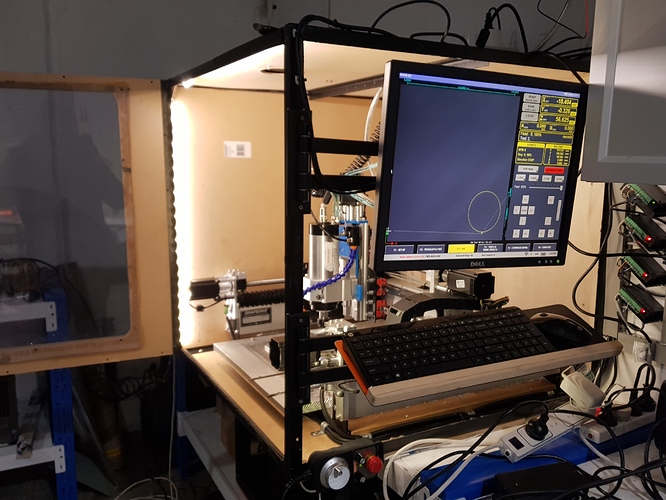

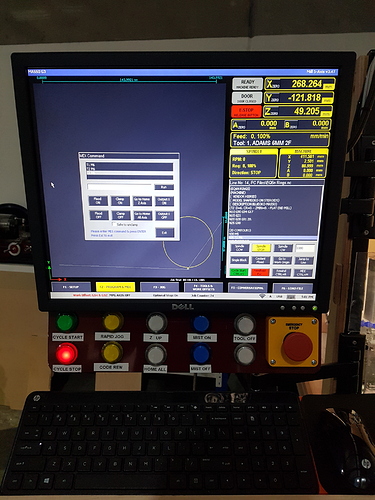

My monitor and keyboard arms…

When working on a part:

When working from Fusion and testing:

When stowed away (and also for tests)

Has someone built a 5 axis Shapeoko?

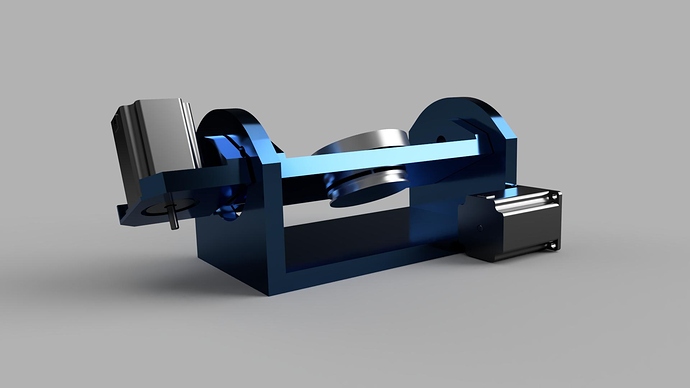

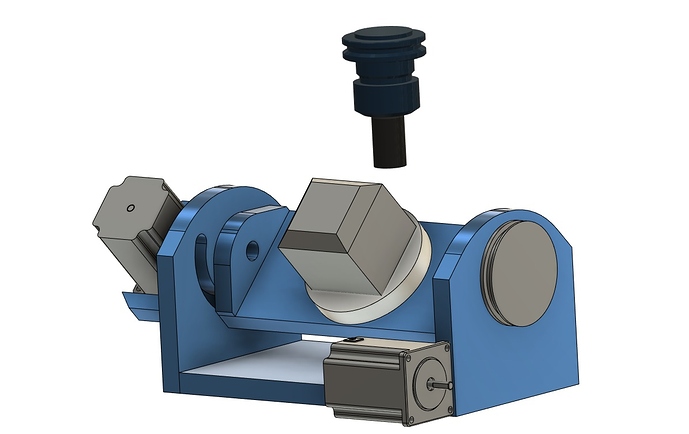

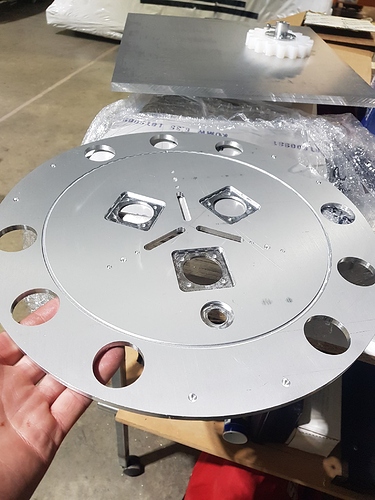

i am drawing this:

The 16mm 6061 alu should do, i hope it can be usefull, super happy to have a 5 axis shapeoko, maybe not strong enough to mill aluminium but i want to see it in action

5 axis learning…

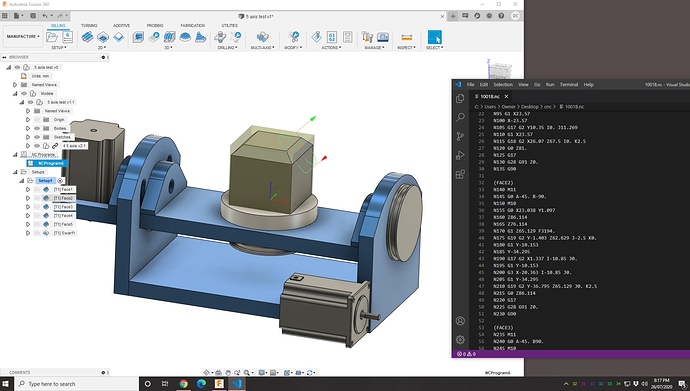

Hi mates how are you guys today, after drawing what it seems to be 4th and 5th axis for my Shapeoko, i started the journey of understanding how to set up the machine in fusion 360 and where WCS needs to be located, also learned how to enable 5 axis post for my MASSO controller, scary stuff the first time you see all of it but i think i may be on the money.

It happens that first you set up a new machine on Fusion and create the new rotary axis… in my case A and C, where A is A on Masso and C is B on MASSO…

Then set the post processor to enable 5 axis and then… How do i program Fusion 360 to Machine the faces that are not on the Z axis???

After watching videos i found a tab called Tool orientation, where you define z axis for the tool, and guess what? Fusion takes care of the machine motion and positions the part on the right direction… cool stuff…

i am still learning about tool warping and Swarf, but this looks promising, i downloaded a 5 axis machine simulator and loaded the code and IT WORKS!!!

On the image you can see my design with a simple cubed part on top… it happens that you need the Stock holder or whatever is there modeled in orde to define a fixure so Fusion knows what is happening, and then, WHERE DO I REFERENCE THIS ON THE MACHINE…???

I hope not to be wrong, but in my case it seems i have to refference the WCS on the spot where both rotation axis intersect, that is where i will set my work piece 0,0,0 and 0,0

Another thing, my A axis movement ranges from -90 to 90 deg and the C axis rotates full 360…

My head sort of hurts from understanding all of this in one go… i hope this info is usefull for someone…

On the image you can see my Part installed on the “fixure” (my designed 4 5 axis thing)… and the post processor output…

as you can see… the operation on fusion is machining one chamfer on the cube and the code is telling the A axis to tilt to -45 deg and the B axis (C on fusion) to -90 placing the part on this position for machining:

I really hope i am not so wrong, i will start to make the rotary table this week…

Bye Guys!!!

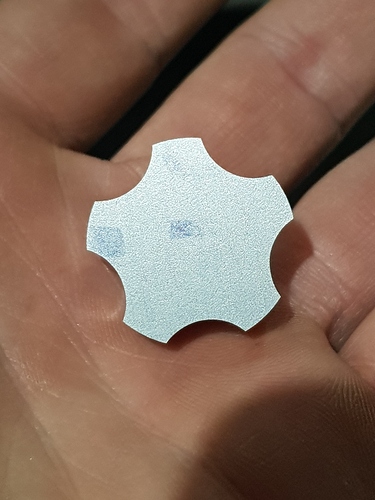

whooo hang on now - is this a 5th axis knob, as in made on SO3 5th axis?

i wish!!! its on my normal 3 axis… 4th and 5th not ready

We have a Mazak Integrex 5 axis Cnc Machine which is more of a lathe with an articulating spindle, a lower turret and 2 chucks. Anyway… The programs are crazy looking because it changes planes constantly when the spindle has to get in a position to be perpendicular to the plane its machining. As far as work offset positioning, if you program the part with the work offset at the center of the part, where it will be rotating around, you shouldnt have to find any additional workoffsets after that and the A, B, or C axis will just rotate. Your Z’s will look weird when it rotates but thats it.

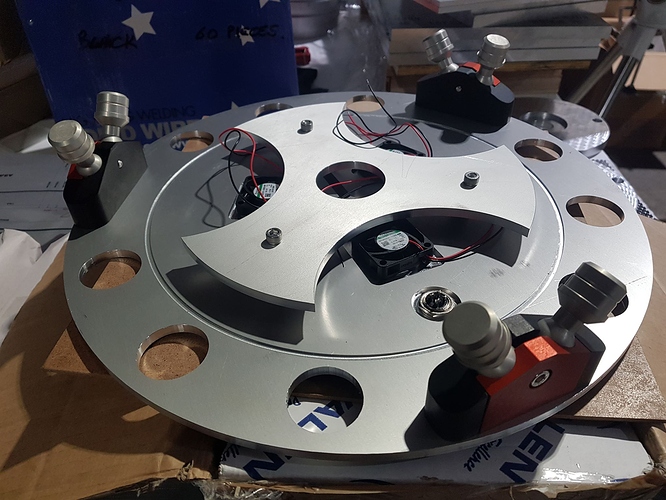

Today’s update!!!

Love buttons!!!

LED on the green Button when running the Cycle/

Led on the red button after stop is pressed, or soft limits reached

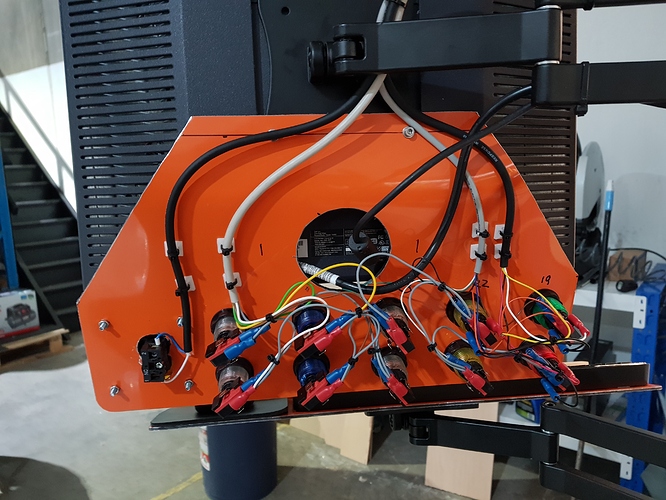

Bit of wiring done

I can’t wait for the ATC to arrive!!!

And then the enclosure for the machine will happen!!!

Way past what I had envisioned for upgrades. Very advanced setup! I suppose once you build the first one, the next one is much easier, ha ha. Can I put in a order for a replica once it is tested and perfected?

Congrats and watching your progress with much interest!

If you were to design and build a 4th and 5th axis, IMO, you should also make provisions to remove the base install the unit lower so you can have appropriate room for rotating your parts otherwise you will only be able to machine very small items.

I’m very curious about these parts!!! What are you cutting?

you are very right!!! i am thinking about a new enclosure and more changes to accommodate 2 more axis…

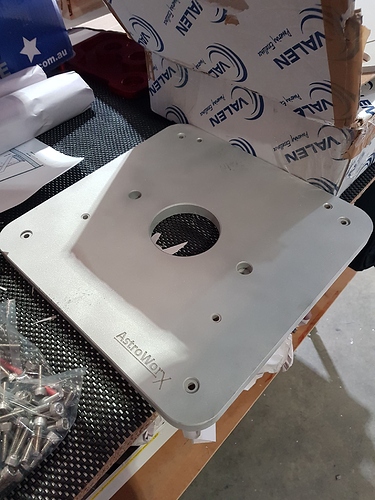

Telescope parts and accesories for astronomy gear

Out of curiosity, what do you think you spent on the electronics setup? A masso is around $600, drivers depending on spec with post supplies can run in at over $200, relays, buttons etc all add up? The ATC is is around $3k?

the second hand Shapeoko 1600 AUD

2.2k Spindle 800 aud (with vfd)

Tool changer adaptor 2700 AUD comes with pneumatics, tool holders etc…

masso with accesories 1200 AUD relay boards, jog, etc…

Stepper drivers, Power supplies and cables 400 AUD

Ballscrews, rails etc 300 aud

I know… should have ordered a HAAS, Okuma seemed expensive…

But the enjoyment you’ve been having is incomparable to any dollar value (even AUD :))