So, I initialize my machine, comes up front to install endmill…good so far. I install a 201 1/4" bit and it goes to the Bitsetter and does its normal thing (2plunges, slow on the second plunge) the I set and zero the Z, Y, And X axis where I want it. I load my file, click start, and to the front for the bit install again, I click resume and on to the bitsetter again and does the double plunge thing. After that, I’m set to start my router to 18K and click start. Here is my problem…as soon as I click start, it goes to the start spot and plunges THRU my darn stock!!! WASSUP WITH THAT?!

How is the origin specified in your file? Top or Bottom?

Where are you specifying it relative to your stock? At the spoilboard surface or on the top of the stock?

Post the .c2d file, generated G-Code, step-by-step notes on how you are securing your stock and setting zero relative to it, and a photo showing an attempt at cutting still in place on the machine and we’ll do our best to work through this with you.

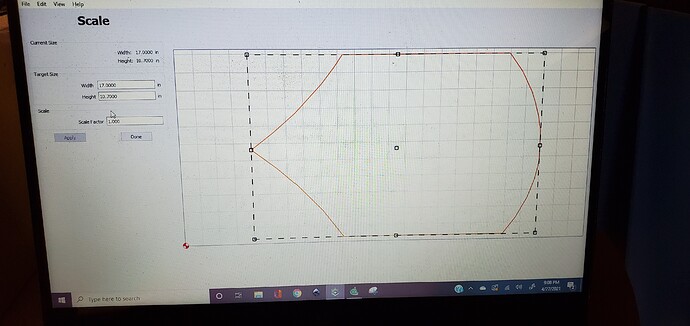

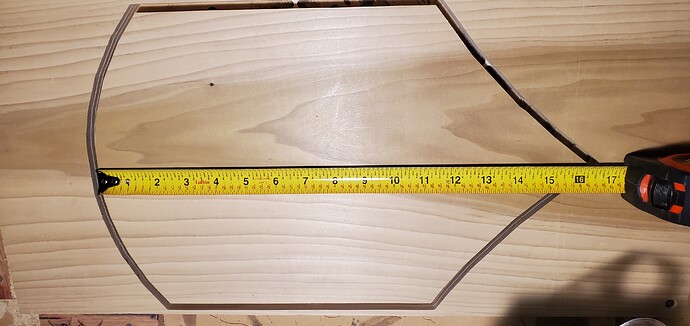

So I got it to act right after shutting everything down, resetting the setting to am Shapeoko XL, it was set to XXL for whatever reason but now it’s not cutting my project to scale with CC. Pictures of that on the way…

Dpi?

How do I fix that other than compensating for the size missing in CC?

What sort of toolpath are you using?

If it’s a No offset contour, then then dimensions will be off by the diameter of the endmill (which looks to be the case).

It was an outside contour cut

But I’m checking now and ensure it’s not and running it again for the 3rd time…need this project done by tomorrow

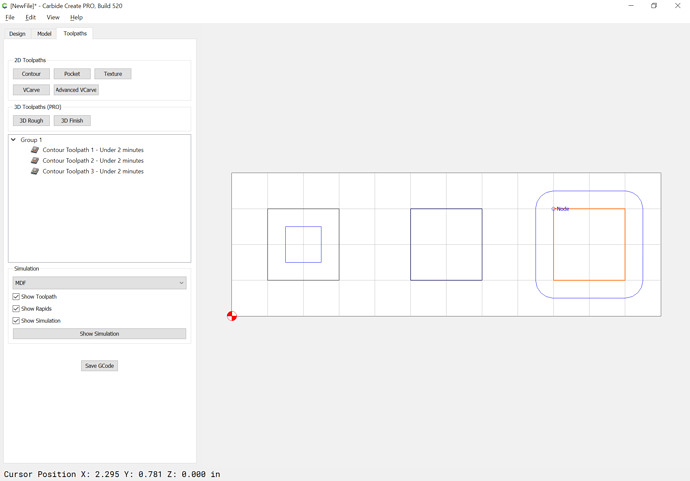

Have you calibrated for belt stretch?

Tried making a small calibration test in a piece of scrap?

Try this one:

threesquares.c2d (16.1 KB)

What does the square on the right measure when cut?

Another consideration is Climb vs. Conventional Milling and tooling engagement — where possible avoid slotting and add geometry and cut as a pocket (Making vacuum hose adapters and/or Adding geometry to cut as a pocket with a finishing pass ) and consider leaving a roughing clearance and taking a finishing pass.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.