I tested the 1/8" ZrN single flute endmill last night and ran into some strange issues with it. It cut very poorly on the bottom of my part and the sides were rough too. I believe I was pushing the endmill too hard and started getting chip welding. However, I never had any chatter. My adaptive milling settings were:

DOC = 3mm (0.118in)

Optimal load = 19%

CPT = 0.03mm (0.0012in)

RPM = 28,000

The curious observation I noticed was a dulling of the edge of my endmill. The shiny goldish-color of the ZrN was turning silverish-aluminum colored. I also noticed that the cutting edge of the endmill would have a chip stuck to it after some tests. I was curious since I haven’t seen this in my standard 2-flute ZrN endmill I use so I took some pictures (shown below).

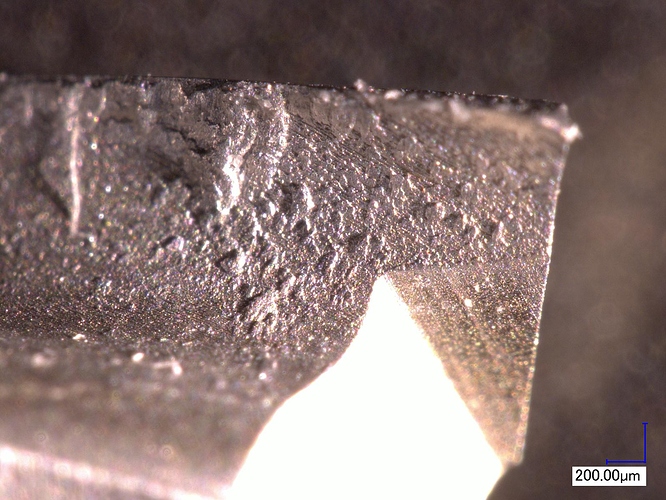

This first picture is of the bottom of the endmill. It is held at a perpendicular angle so you can notice that the bottom cutting edge is not 90 degrees from the endmill, which means it does not have a square bottom. I didn’t realize single flutes are made in this geometry and I would guess that would put a fairly high stress concentration in that tip instead of spreading it across the entire bottom of the endmill. There is a reason for this, I just don’t know it. You can also notice that the endmill is coated in aluminum, which is causing the discoloration.

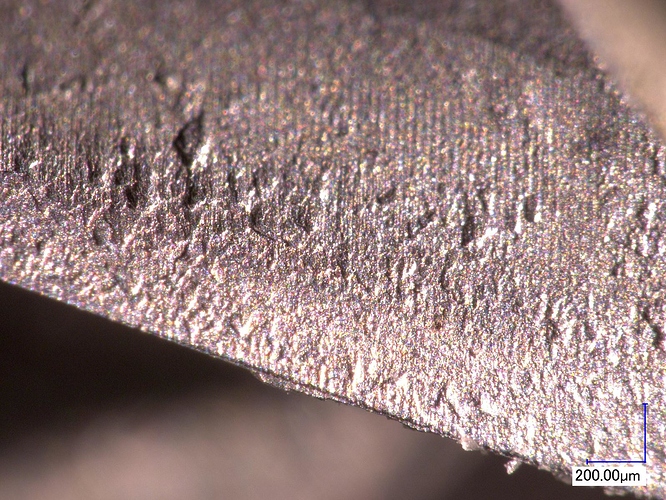

A closer view of the material stuck onto the endmill

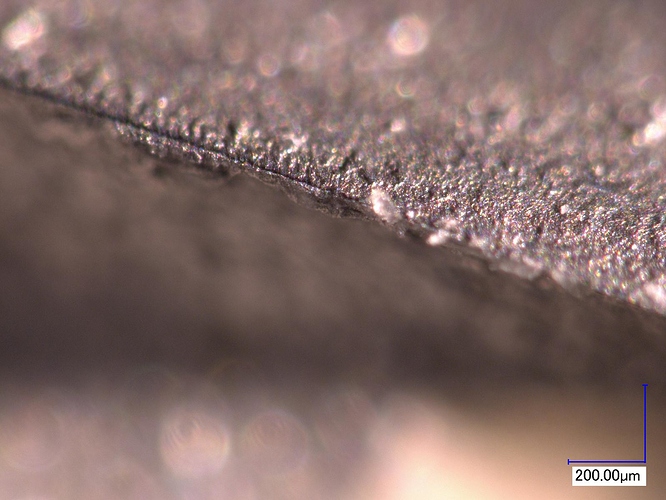

For reference, here is a picture of the flute that never saw aluminum and a picture of the cutting edge if you are curious.

Here is a picture of the backside of the cutting edge and then below that is a picture of the bottom cutting edge that saw aluminum. Notice that the edge is not as sharp anymore since there is aluminum welded to it now.

I found a set of parameters you shouldn’t use. I’ll do more testing this weekend and see what works.