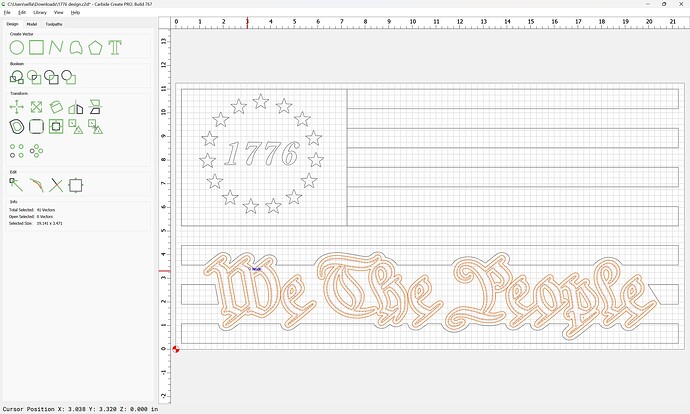

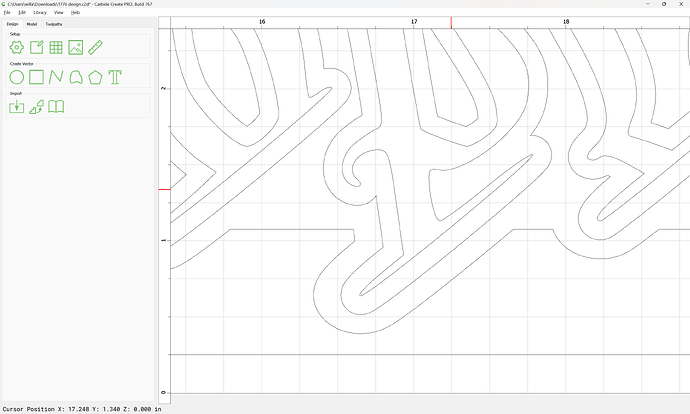

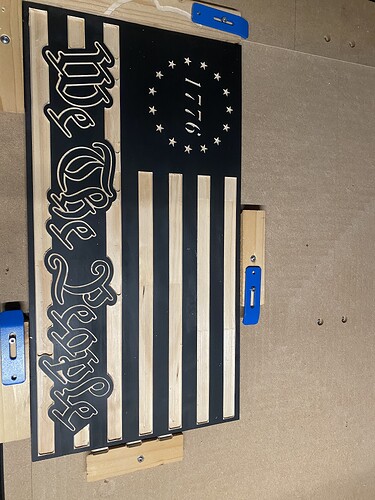

We bought a shapeoko 3 XXL before Christmas last year and ive been reading and trying to learn from all the topics and etc here. ive been designing some of the wooden flags (beginner projects) buying bits here and here and trying to figure it all out. Im currently working on a “we the people” flag and cant quite figure out how to get the result I want. Im using the free version of carbide create and want the “we the people to be pocketed out but not take an hour and a half. Im thinking maybe the design is too small to use the 1/4” endmill to pocket it, yet when i choose 1/8" endmill or ball mill it takes way way too long. here is what im getting vs the result i want. Any help would be greatly appreciated

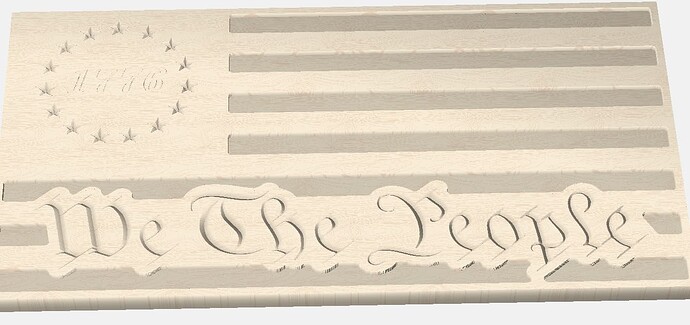

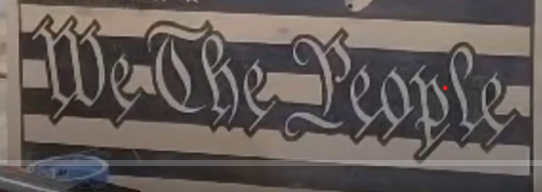

this is the result I would like

The problem here is one of “Figure-ground reversal”, please see:

and

If you have difficulty applying these concepts, please upload your file and we will walk through this with you.

1776 design.c2d (304 KB)

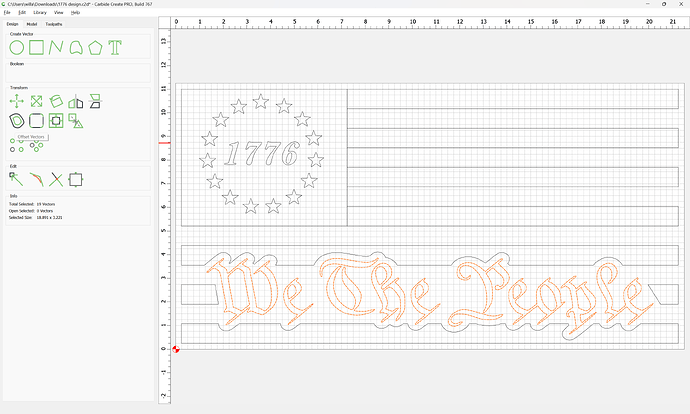

here is my current design, I have several tool paths for the “we the people” part just to see different results.

As noted, this isn’t a toolpath issue, it’s a matter of geometry.

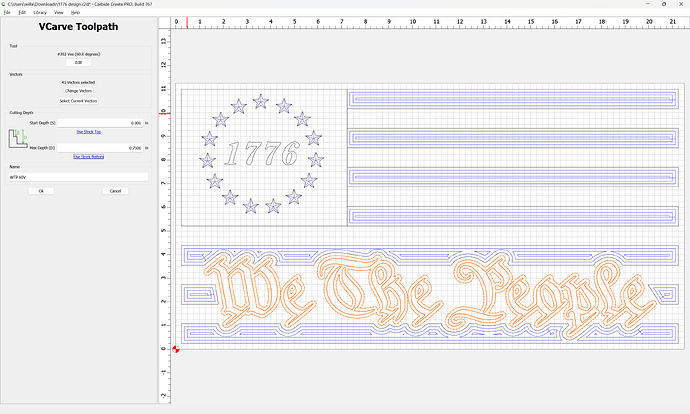

Currently you have:

Note that it does not have geometry around it which defines an outline around the text.

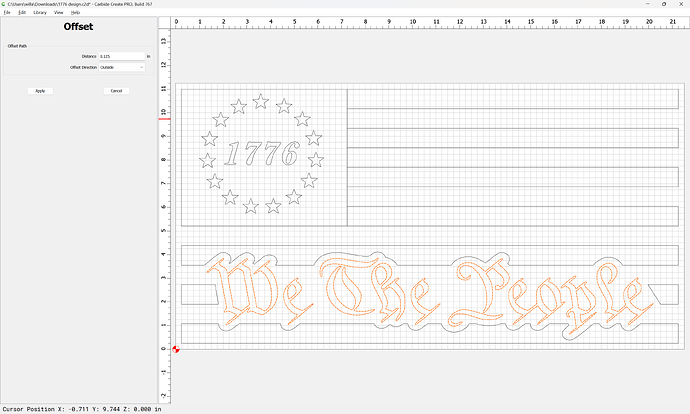

Select the text:

Offset to the outside:

Apply

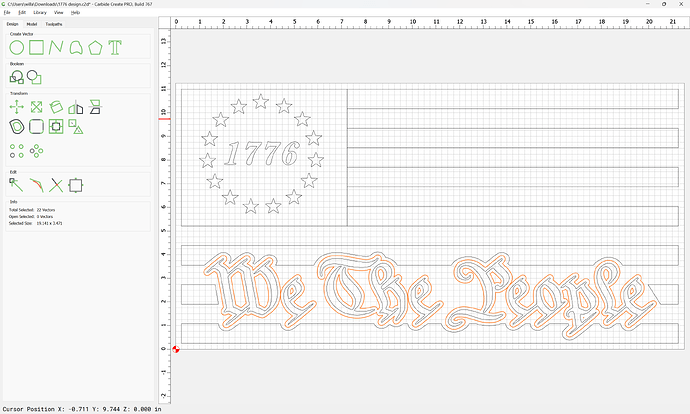

add the text to the selection:

Edit the toolpath to use this geometry and allow it to cut as deep as is necessary to describe the region in question:

and disable the engraving toolpath

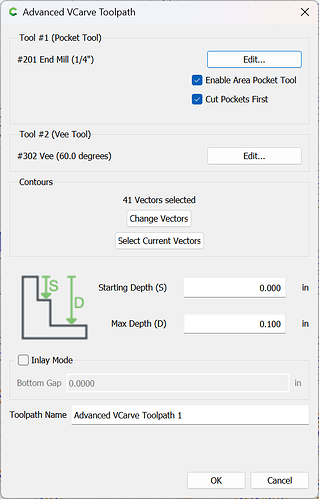

Note however that there are some regions which cut more deeply than others, an Advanced V carving toolpath would be better:

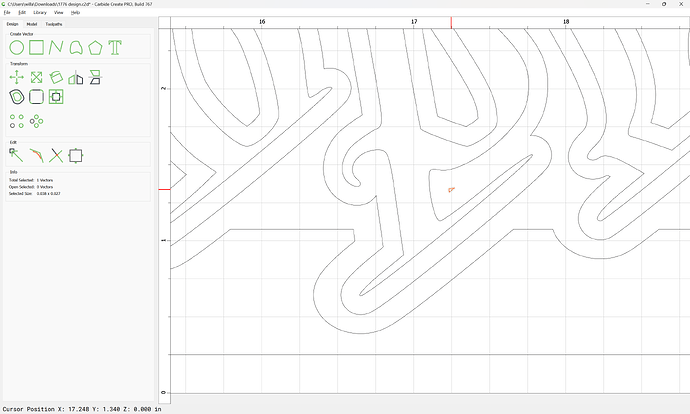

Note that there is one small bit of geometry which is problematic:

deleting it:

yields a better result:

Actually, cutting the stripes and the other text thus has a better appearance:

Attached as a v7 file.

1776 design_v7.c2d (696 KB)

I see, Ill give it a shot and post a pic when completed! thanks for the help!!! one more question, being the advance v carve tool path and there being 2 tools listed in it, the 60V and the 1/4 endmill will it give me a chance to re zero the Z at the change? or am i thinking about it wrong.

You will need a BitSetter for that tool change.

is there a way to create separate tool paths for it as i dont have one yet?

You need to first save the GCode. If you are using CC version 7, you have to do this from Carbide Motion. You should disable any other toolpaths first.

Once you have the GCode for just the Advanced VCarve, you can separate it into two files here:

https://fenrus75.github.io/FenrusCNCtools/javascript/gcodesplit.html

Here was the result, if you look closely it didn’t quite cut all the depth around the “we the people” maybe I can just create a tool path to redo that section. It didn’t pocket out the letters either, so I’m not sure what to do other than use the smaller bit to fit all the geometry.

l

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.