I might be a little unfair saying it’s barely sufficient but for me, it’s the truth.

If you’re making really small stuff where you don’t need to remove much material at all, the 883 Pro might be okay.

But I’ve found for most of my projects, I need to remove a bunch of material.

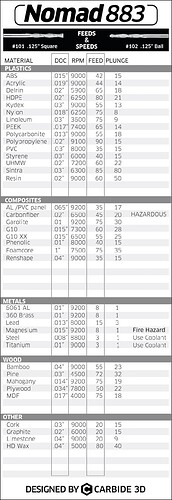

The recommended MRR from Carbide 3D is 0.16cm^3/min:

And here, I was able to get the MRR to ~0.8cm^3/min.

What does that mean?

It means that a 5cm x 5cm x 1cm pocket (25cm^3) takes over 2 and a half hours to finish with Carbide 3D’s recommended settings (the “out-of-the-box experience”) or half an hour when you tinker and push the machine to the edge of failing.

If you buy the Nomad 3, you can cut both of those numbers at least in half.

And that’s without including the time for rapid moves and whatnot, that’s just cutting time.

If you’re making really small parts or just engraving, maybe these numbers are okay to you but I found that it was just too much when I wanted to make useful mechanical parts.

@luisce89 I’d recommend you estimate how much material you’d typically want to remove to make a part and use my MRR numbers above to get an estimate of how long your jobs would take.