Wherever you read that, it’s very, very wrong. A typical router used on a Shapeoko will have at least 600W of power (i.e. 4x the power of the Nomad 3) and be able to handle higher MRR cuts as a result.

Take the Shapeoko DOC and divide it by 4 and you’ll be closer to something reasonable for the Nomad.

In my experience with the Nomad, what you want is 60-100% stepover and however much stepdown you can get without the machine making unpleasant noises. The Nomad, at least the 883 Pro, does not do well with high-axial, low-radial toolpaths.

Back to the 1/4" question, I’ll disagree to an extent with @Damon2021 and @WillAdams. 1/4" tooling can work on the Nomad and can even work better on the Nomad than 1/8" tooling. In particular, the increased diameter means that at a given RPM, the surface speed is higher and the cutting speeds are reduced. It also means there’s more space in the flutes for chip evacuation.

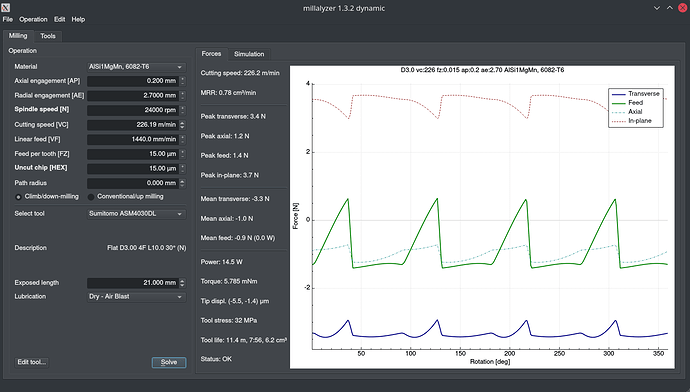

On the first point, here’s a cut with a 3mm endmill:

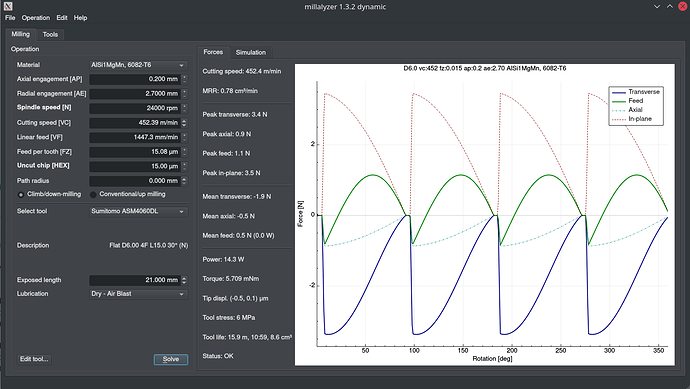

And here’s the exact same cut with a 6mm endmill:

You can see that with 2x the endmill size, the mean cutting forces are cut nearly in half, the tip displacement (deflection) is reduced 10x and the tool stress is ~1/5th of what it was.

However the peak forces, torque and power haven’t changed a whole lot and those are the limiting factors on a Nomad. Using a larger endmill won’t help you overcome them. You won’t get higher MRR just from using a 1/4" endmill.

Where I think 1/4" endmills make the most sense on the Nomad is multi-flute endmills. A 1/4" endmill has more space in its flutes for chip evacuation than a 1/8" endmill so I think, for example, that while you wouldn’t want to use a 3 or 4-flute 1/8" endmill without a serious setup for chip evacuation (e.g. flood coolant or multiple air blast nozzles), you could absolutely use a 3 or 4-flute 1/4" endmill. The higher flute-count will help you get higher MRR (since you can bump up the feed rate), even if moving up to 1/4" on its own won’t.