Hi all, I picked up a Nomad and need to order some tooling to get started. I see it originally shipped with a few 1/8" end mills. There is some mention about 1/4", but I am not much info. Any help would be appreciated!

This is a pretty good pack that should get you started:

Though what you actually want will depend on what type of projects you plan to do.

There is a collet you can buy to put 1/4 inch shank tooling into your machine, but I wouldn’t recommend that starting out: https://shop.carbide3d.com/collections/accessories/products/25-er-11-collet-and-nut?variant=1256433071

I think that 1/8 inch bit flat endmill and 1/8 inch ball endmill will get you pretty far.

Edit: If you are doing aluminium this bit is amazing: https://shop.carbide3d.com/collections/cutters/products/274z-125-single-flute-zrn?variant=14182006161469

Great thank you. I really only plan on using this for al since the machine is indoors. Don’t want to deal with dust from other materials!

For Aluminium I also 100% agree that you’ll want a single-flute cutter. I’d stick with 1/8" tools and not bother with the 1/4" tooling for the Nomad.

However I’ve found other brands like this one to be much better than the Carbide 3D options.

One thing to watch out for: don’t get the longest tool you can buy, get the shortest you can deal with. I made the mistake of buying the longest tools I could find when I first started because I wanted to cut through thick materials. However I found that the longer it is, the harder it is to get a decent cut with. You want to minimize the amount of tool outside the collet as much as you can.

I’ve had a Nomad since December of 2014, so I have accumulated many bits but I’ll give you the nearly the same answer. 1/8th (aka 102) is the go-to bit for me. And only if I need to go smaller do I use the 1/16 (aka 112). You can go smaller, or bigger, but for the Nomad those two get most of the workload (in my experience).

Those are flat (clean straight) cut endmills, if you want to do 3D contours then the 1/8th ball (aka 101) and the 1/16th ball (aka 111) are what you need.

Eventually you will probably want to experiment with other bits, but those 4 will do just about any job. When I tried the downcutting versions of the flat endmill bits (which Carbide does not sell) I saw the value of those, and the single fluted when cutting metal or plastic… but these don’t allow you to do anything you could not already do with those base sizes, they just do specific jobs a little better.

Only other advice is say that not all bits are created equal. Don’t get lured into less expensive bits, there is already enough of a learning curve. If you get the bits Carbide 3D sells there is less to think about since their software already has recommended settings for those bits baked into their software.

I would caveat this with: when you can avoid the ball ends by using appropriate toolpaths, you will get better results. Sometimes you need them. Often you can do better without in all respects (speed, finish, fewer tool changes)

I would add bullnose (flat end with a radius corner) to the list, since they will most things the flat end will, and many things a ball end will, with better life than the flat end in many cases (no sharp corner to break down). They are the cats meow when you want a fillet on an inside corner.

On aluminium, you don’t even want to consider 1/4" diameter tools with the Nomad, unless you plan on going nuts with replacing the spindle (I will mention no names but there is a thread about this). I have used 1/4" diameter tools for materials like renshape and foam, but anything else, only specialty cutters (thread mills, lollipop mills) where the load can be controlled.

Also, for Al, you will probably want to look to coated tools eventually. You can get better tool life and finer finishes with less hassle, for greater up front cost. (there are a lot of options. See the tooling supplier sites for information.)

If the reason for Al is dust control, look to the broad assortment of plastics, as well. I use a lot of HDPE and Acetyl (POM; Delrin), as well as a good bit of Nylon, acrylic, and polycarbonate. All machine fairly easily with little dust. These are materials that you actually need to go at aggressively (large chips) to get good results, and the Nomad eats these like (I can’t think of an analogy anymore that won’t offend someone, so lets go with the Nomad machines all of these easily).

FWIW, at least when it comes to C3D’s ZrN, I didn’t notice a whole lot of difference.

Like the cookie monster eats cookies ![]()

sounds like 1/8" is the way to go. are the carbide3d tools made by themselves, or by another company?

Welcome aboard another Nomad user!

Think you have all the advice you need already but I’ll throw in a couple of things.

-

The ZrN/TiCN coated tools do help (to my ear anyways), but only if you are pushing hard.

-

If you are worried about dust I recommend a good diet of HDPE plastic. You can take large chips out of it, its way faster and easier to machine than aluminium, and doesn’t build up dust like milling wood will. I pretty much use it for anything that doesn’t require the material properties of aluminium

-

Those Al chips end up… everywhere!

The places the appropriate coatings really help are reducing edge build-up letting the chips slide and clear better. (I use mostly TiCN coated, since they work so well with many plastics, and are Al compatible.)

Not sure if carbide 3d makes their tools. @WillAdams might be able to tell us.

I will say after going through some issues on my end that seemed to point to cheap tooling I got, Ill be restocking on some more carbide 3d bits.

is it just me, or are these tool websites really annoying to use

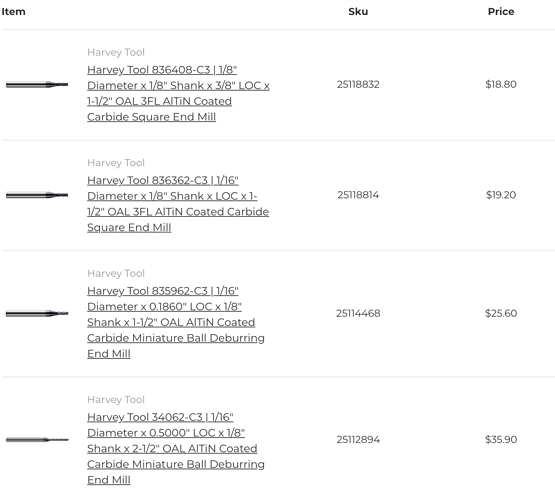

so after looking at what everybody has suggested I’m going to get started with the following:

i am also picking up a set of metric and standard guhring drill bits.

Yes, the sites really are a pain to use.

What do you mean metric and standard, metric is standard

Just one thought here. That AlTiN coating on those tools are probably not the best if you want to mill aluminum. From my limited understanding AlTiN is for ferrous metals where the high heat creates some sort of lubricity with the steel or whatnot. The Al in the coating is supposed to get a little too attached to the stock when milling aluminium. Kudos for going for quality tools but if you can find ZrN or possibly TiCN coating that would be what to go for. That being said uncoated carbide works too!

You are right haha, I copied the wrong column down from the Harvey Tool website  I meant to add the uncoated versions!

I meant to add the uncoated versions!

I wish metric was the standard

It is the standard for 7.3 billion people

Remember that the next time that you’re getting a 6.35mm screwdriver bit.

It was a lot easier for Europe to switch to a standard when they were rebuilding their economies as a part of the Marshall Plan — for the most part Imperial measure is just a decorative labeling which is for the most part workable enough.

That said, I find Imperial measure far easier to work with, esp. on any project which involves division into thirds — doing that in metric always takes me back to the problems at my previous job of layouts done by folks in metric countries where the specs would specify a column layout where columns + gutter(s) != textblock width and none of the ads would be the correct sizes totally wrecking the automation system I had programmed and its matching cast-off — I’ve never seen a spec. done in picas which had that problem, and yes, for some projects in the workshop (or on the machine) I’ve gotten out a pica rule to do nice even divisions.

It wouldn’t be so bad if Japan had used one-third of a millimeter for their type measure, kyu, but instead they chose q, 0.25mm.

I’m purty sure we were doing OK until some here started thinking somewhere else in the world was so much better/more sophisticated than here.

“Numbers is numbers; work them out.” from my old chemistry teacher in high school.

I think “here” moved on to metric in a spirit of worldwide collaboration, not jealousy or envy.