hi everyone

just a quick one

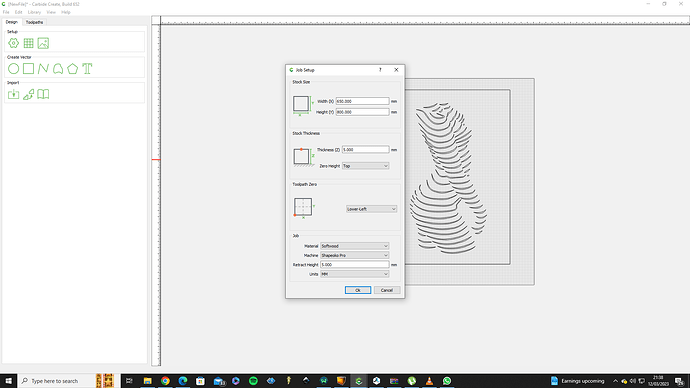

using carbide to make a project and i have set my wood to 5.5mm my wood was 5mm

but the cut depth was was 8.5 mm i missing somthing here

thanks marko

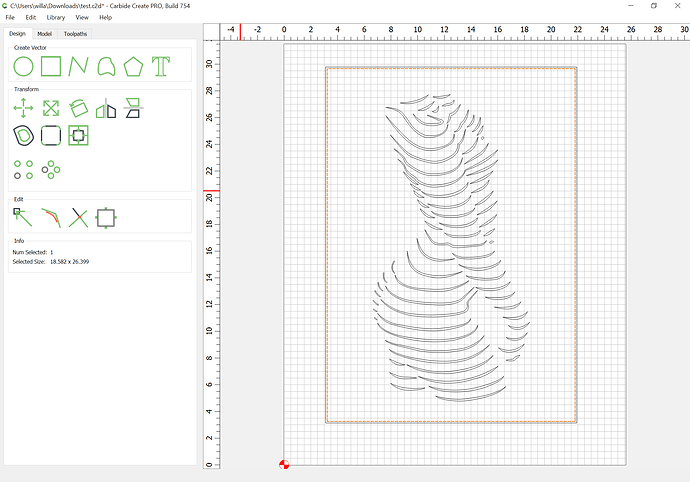

Please post the .c2d file.

Where is the origin in the file?

Where did you set it relative to the stock?

Which Z-axis does your machine have?

What is your Z-axis configuration in Grbl?

Are you cutting a slot just as narrow as the tool? What feeds and speeds are you using? In what material?

test.c2d (1.8 MB)

wood is 5mm z .5 steps

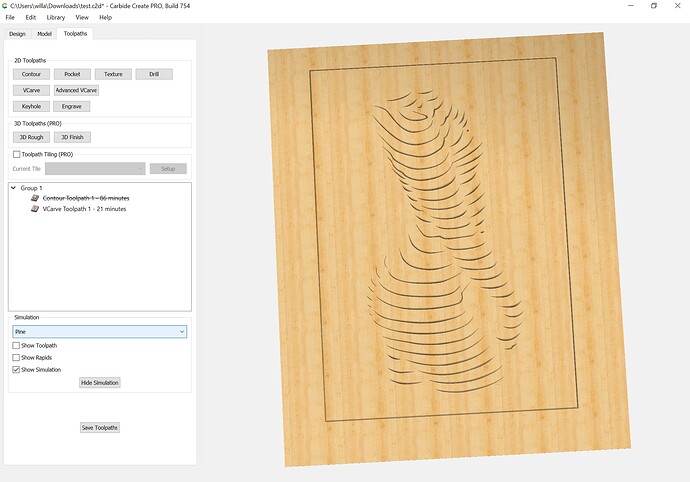

You can set Zero Height in the Stock Thickness section to whichever is more appropriate to set the origin relative to the stock.

For decorative work such as this, Top is best, and is our recommendation to use unless there is a compelling reason to use Bottom.

A further consideration, if you use a V carving toolpath and inset the border:

You’ll get a result which may be more in keeping w/ what you want:

thanks will give it a try

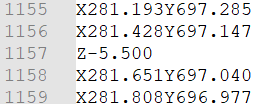

The G-Code is correct. the Lowest Z value in the program is -5.500

So if it’s cutting 8.5 deep on the machine it’s either mechanical (too aggressive a cut & the tool is slipping or the Z axis is getting pulled downward.), or it’s in your setup.

I make it a habit to double check my Z before executing a program. Right before the “Run → Start” step in your process, jog the tool somewhere on the part (I like somewhere near the center) and move the Z axis down to touch the top of stock. Look at the Z on the readout.

where possible avoid slotting and add geometry and cut as a pocket

and/or

and consider leaving a roughing clearance and taking a finishing pass.

This topic was automatically closed after 30 days. New replies are no longer allowed.