Has anyone used their skills and machine to crank out a wicked pinewood derby car? I’ve got a super casual event coming up with some of the kids in the community and figured it might be a good time to play with my Nomad a little more.

Tricks to make it go fast

Angle the axles up a little so as the wheel spins, it moves away from the wooden body of the car,

Polish the axles

Lift one wheel, so only three wheels touch the ground

Get the weight as far back as high as you can get it. You’re changing potential energy and kinetic energy.

CNC can help you get the axle holes exact. that would help

You probably know all this. Best just to have fun.

Look up “Mark Rober” video about Derby cars on YouTube. Scientific ideas.

Thank you for the “I should have had a V8!” moment. ![]() I appreciate grounding me back in reality.

I appreciate grounding me back in reality. ![]()

I wanted to do this as well but we did not have enough time to pull it together this year so we went the manual route. I did buy an extra “official” kit so that we could experiment and be ready for next year. We still had one kid with a second place finish and another with a design award.

The overall winner was just a thin flat piece of wood that weighed exactly the max amount.

I did buy the jig online that helps drill the axle holes perfectly though. It also has an option to mount one at at angle so only 3 wheels touch the track which is supposed to help.

Do be sure to check the rules being used by your local pack and district. Some are quite restrictive in what you can do. For example, there is a pack that does NOT allow drilling the axle holes at an angle, but you can get away with a bent axle positioned so the wheel doesn’t touch the track. Go figure.

As to where to place the weight, the best is just a little forward of the rear axle or the front will have a tendency to rise. You need a little weight on the front just to prevent that.

When you do check, ask for all the details. I’ve heard of those that don’t allow thinning the outside of the wheels, others that don’t allow any modification to the wheel at all, even those that don’t allow any modifications to the nails used as axles.

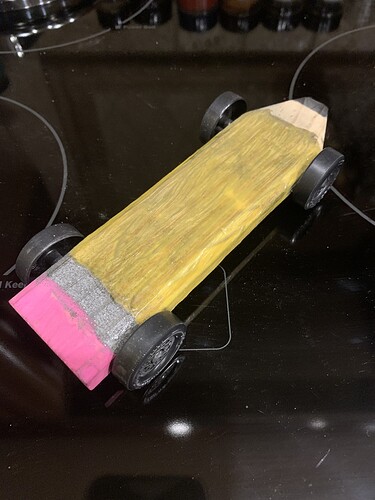

My son’s design, cut at home. Absolutely the fastest car he ever built. It beat the winner of the race for the next 3 years as the car can only be used for one race season.

Yeah, I definitely lost control on my sons car or should I say my car along with the help of six other NASA engineers. We didn’t quite put it in a wind tunnel, but we thought about it.

Bad on my part. someday I may grow up or not!

Certainly would have loved to be a fly on that wall as the ideas started to flow!

I have assisted with Pinewood derby cars in the past. The most important thing is the KIDS need to do the majority of the work to stay in the spirit of the Pinewood Derby. So get the kids to pick the design and let them use Carbide Create with supervision and then help them mount the work and hit the start button. Just dont do it for them. Get them involved and let them learn something new.

Very nice. Milling every face of the block I assume?

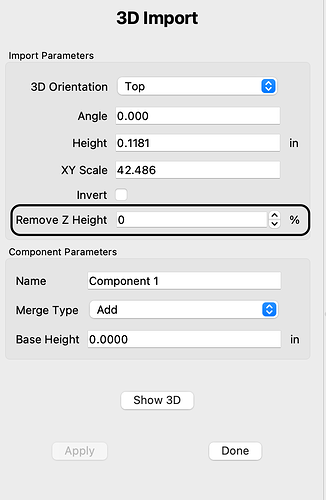

Yes, in Carbide create pro you can pull an stl in from sites like thingiverse. I used a block of pine (not from the kit). If the rules require using the kit you’ll have to glue pieces on. You want the exact outside dimensions to be 2.75 x 7, height depends on the car, probably between 1.75-2.75 (Rules say “The overall length of the car shall not exceed 7 inches. The overall width of the car shall not exceed 2 ¾ inches. The car must have 1 ¾” clearance between the wheels.”) Set the dimensions in carbide to match and the check to see that the stl fills the space. It may require distorting the proportions a bit.

There is an option in pro to Remove z height.

Use this or draw a line just inside the image, I found it works best if you don’t let the machine try to carve the steep sides. Carve top and two side separately. I carved the front and back if I wanted a lot of detail. Make your own pockets for the wheel wells, as the stock wheels won’t match the proportions of the stl. Make the pockets 1/2 inch deep. It might be easier to cut the axle groves before the carve, take the measurements of the CC design (they won’t line up with the stock groves). If speed is a concern you’ll want to hollow as much of the inside as you can and add weight to the back. Last tip, use a practice block before you throw the real thing in there.

Hope this helps

We are past this years event but pre-planning for next years.

My dad was an accomplished carver and I had (still have) some cars 45 years ago that were pretty nice. I helped on them of course. Some were fast and some won for design.

My boys were too young for much of the tool work this year but if I make a concept car for them maybe I can get them really into it next year. I am hoping having them assist with the design and machining and then doing the sanding and finishing meets expectations these days. I don’t think the rules restrict you to the traditional tool set.

I carved cars for all the adults involved in the Derby. Hosted about 50 kids in my wood shop to cut their cars out. lots of fun

Ha. I have twin 8 year olds and don’t really want them both in the shop at the same time. They distract each other and me too much. Maybe best to do them separately so they can’t spy on each other’s efforts.

What a talent!

Inspiring for sure.

Cant wait for the day i can produce something similar.

Is Pinewood Derby for adults now? This was something we Boy Scouts participated in 65 years ago.