I am new to CNC’s and have just started trying to use it. I was trying to make a tray off of cut rocket last night, and it did not leave a outer lip on the project like it should have. I am 99% sure the design in carbide create was correct. Could this be because we did not zero the X and Y axis correctly?

Which tray? There’s a bunch of them. And does the project have the toolpaths? Or did you create them? If so, can you share the .c2d file?

It was the valet tray. It had the tool paths. The file is on a different computer than I am on now, but I will try to send it in a new message.

tray 1-10.c2d (68 KB)

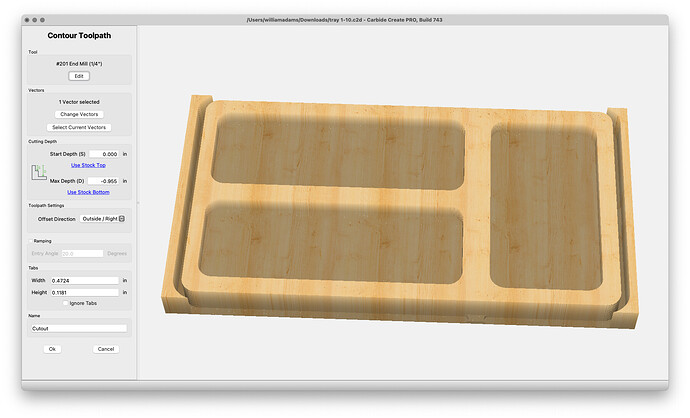

The perimeter cut falls short of the stock thickness:

It also cuts quite a bit more deeply than the 0.75" of the cutting flute length of a #201.

Where possible avoid slotting and add geometry and cut as a pocket down to tab height or the penultimate pass:

It could be a misplaced zero point, or just that the stock isn’t wide enough. Your outside vector is 12.992 x 7.087, So you want your stock at least ~7.25 x 13.25.

You set your stock to 0.980, but your contour path (Cutout) only goes to -0.955. I would cut it to 1.0" deep. The tabs will still be 0.1" thick.

Thank you for your help.

This topic was automatically closed after 30 days. New replies are no longer allowed.