Hey everybody, I had a question concerning Fusion 360 for those of you that use the free version. Is it possible to create a “pause” after a toolpath has completed instead of it returning to the initialization position? When using clamps, this could create a huge problem if you aren’t paying attention at the end of the toolpath and it hits the clamp on the way to the home position. I have just been hitting pause at the end and turning off the CNC manually. Would be helpful is there was a way to stop it automatically. Thanks in advance!

What post processor are you using?

This can be handled in the post processor with built in and/or user configurable options.

You can also zero off the center of the material then you would stay away from the clamps when you are done.

just adjust your safe height in fusion to higher than the clamp, and it will retract above said clamps when going home.

That’s not always possible. Thick stock with longer endmills sometimes leave little room.

Like I suggested above, this should be handled in the post processing.

It is the default 1001 and WCS is 54 (G54). I am running the Shapeoko Pro XXL as well

this is true, but if thats not the case, its definitely an easier option.

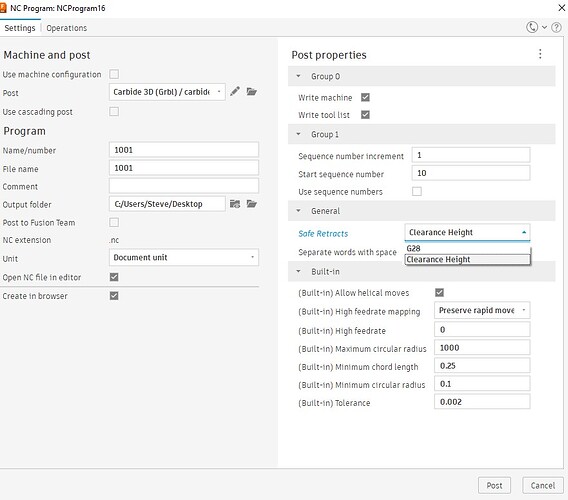

Are you using the Carbide 3D post?

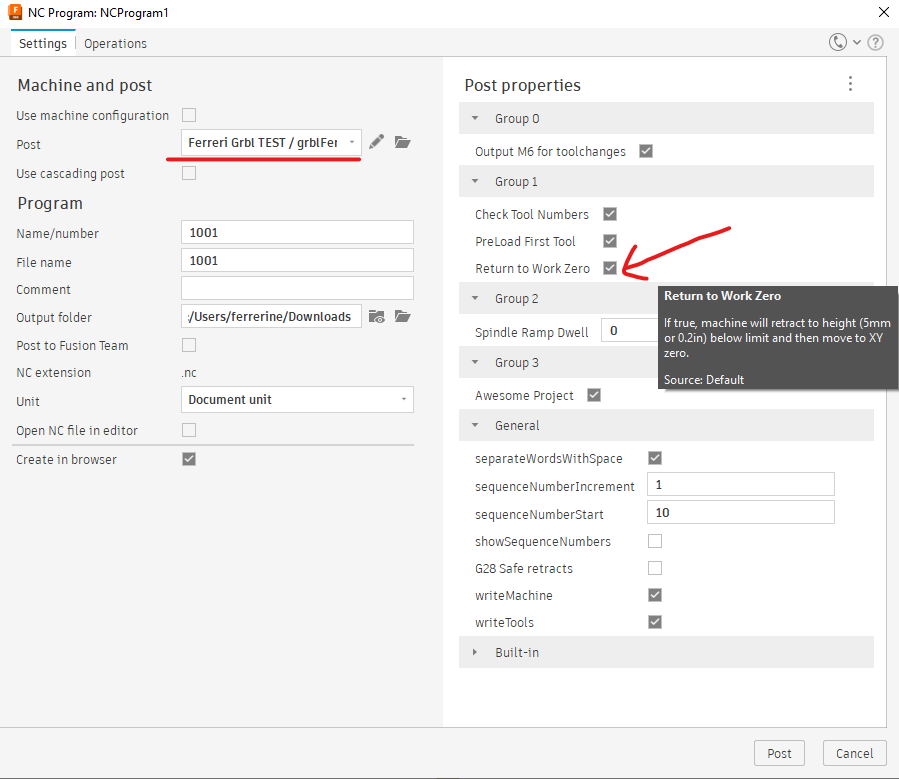

You can try my version. It allows for the option to not return to XY zero at the end of the job. The bit will retract and the job will end with no XY movement.

Yeah I believe its the file that I downloaded and uploaded for the machine. Sorry I am new to Fusion so this is a steep learning curve for me. I will try it out! Thanks!

What’s the purpose of the “Awesome Project” checkbox?

I will test it out. Thanks again for your time and input Neil. Its much appreciated.

It increases the awesomeness of your project by 42%. That’s how good @neilferreri post-processor design skills are!

Does this allow manual toolchanges? Is that what that “Output m6 for tool changes” is? I have had to manually export each job in order with the tool being used and thats annoying. Does this allow you to export the entire CAM operation? I am on the free version.

if you are using the regular Carbide post processor, from fusion360 it should automatically do the M6 toolchange so the machine waits for you to change the tool. or at least thats how it works with my Nomad 3

ymmv on a different machine, im not sure how they handle tool changes.

Mine has always made me export each step by tool. I cant just export the entire setup on the free version unless im missing something?

No way around that limitation on the free version. You can always combine toolpaths after you post process.

ok gotcha. Again, Thanks for your help and your time

Well of course. You can combine any combination of toolpaths using the same tool. @XxPUNISHER78xX was wanting to output all operations for all tools in one file. The hobbyist license doesn’t allow that. I believe there’s an add-in that gets around some of it and I’m sure @fenrus created a post -post processor.