Bwood34

April 27, 2020, 2:44pm

1

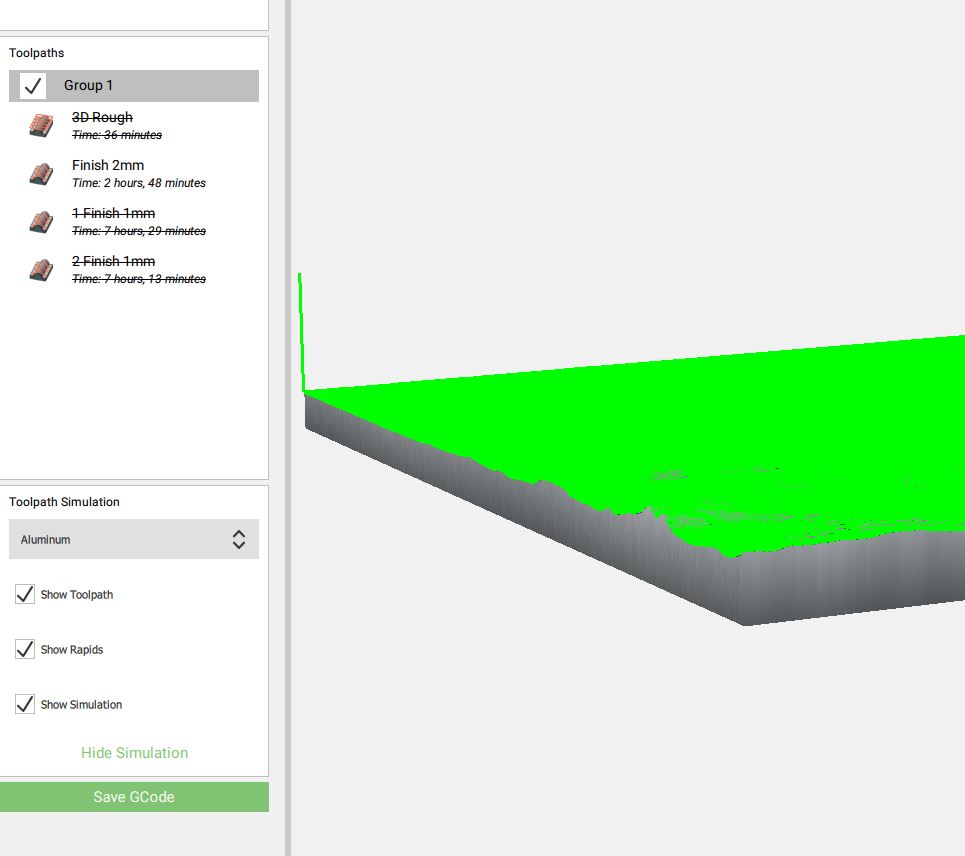

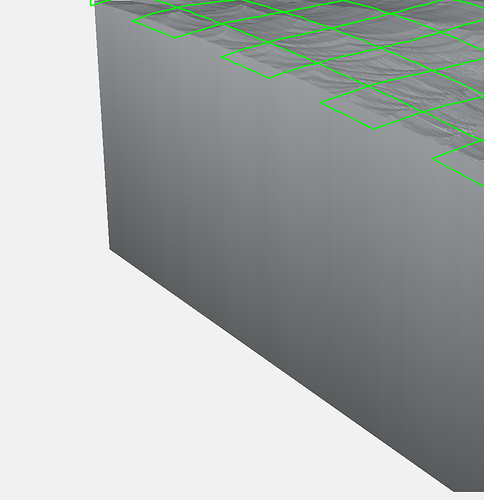

On a project at the moment, I’m testing the machining and rendering of a topographic map of the Montpellier region in FRANCE.

And I have this problem, when I finish with a 2mm Square endmills, no problem.

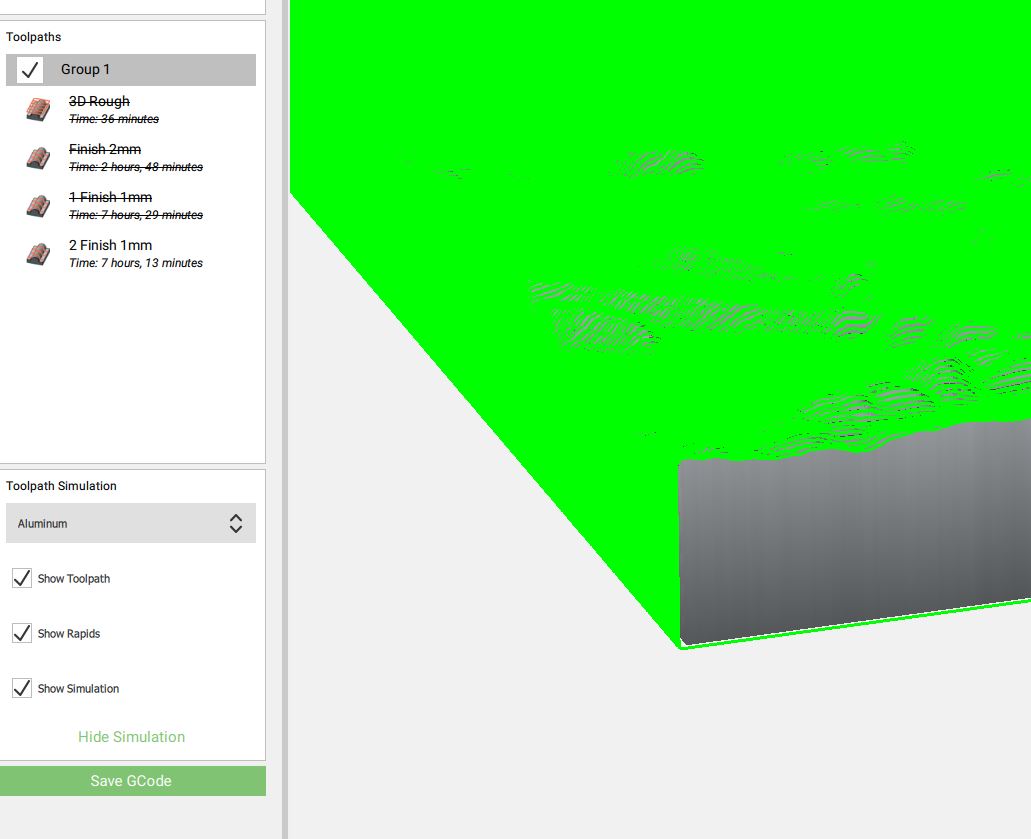

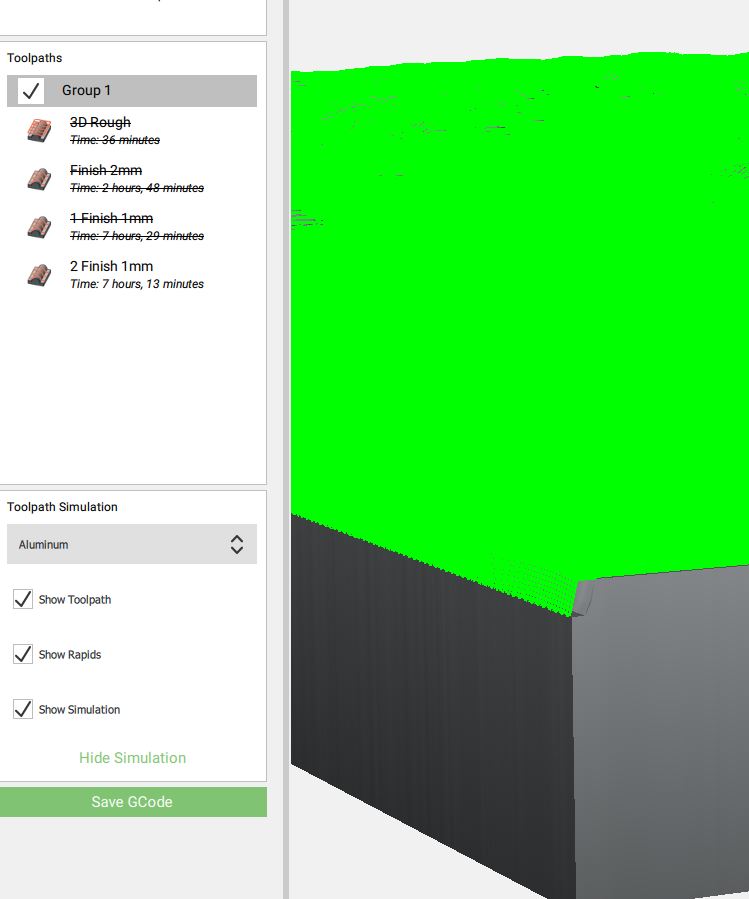

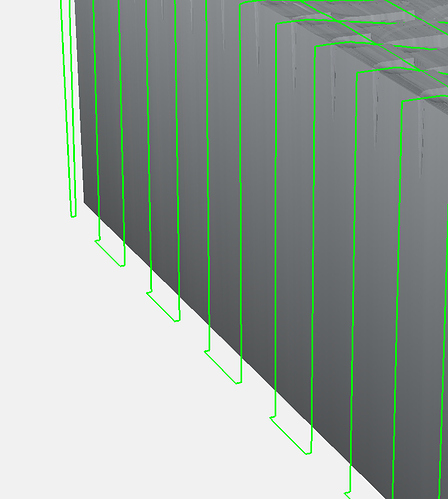

But when I do a finish with a 0.8mm Square endmills, the machining is done on the side of my stock. Shouldn’t it be?

Bwood34

April 27, 2020, 3:24pm

2

Julien

April 27, 2020, 5:31pm

3

I wonder if this is an effect of the “bug/feature” that @fenrus reported in the challenge thread (that the toolpath is computed up to the edge of the shape, without taking the endmill diameter into account)

2 Likes

Bwood34

April 27, 2020, 5:57pm

4

yes I read his comment this morning, I thought I’d mention it, if it’s another problem…

Julien

April 27, 2020, 7:47pm

5

Oh and by the way, I reproduced the same behavior in a different test of mine 5min ago:

stock material defined as (74mm x 125mm) dimensions

3D bounding rectangular shape defined at (74+2mm) x (125+2.5mm)

when using a small enough endmill, in my case #111 (1/16"), the toolpath “overflow” over the walls of the modeled stock

if change the tool to a 1/4" endmill, I get what I wanted:

@robgrz may be able to comment about how edges are managed in CC Pro toolpath generation, which would probably answer both our common question and @fenrus ’s.

2 Likes

system

May 27, 2020, 2:44pm

6

This topic was automatically closed after 30 days. New replies are no longer allowed.