I’ve been dealing with the exact same problem. My 16gal Dewalt compressor works great for sandblasting, painting and air tools but is way waaaaay too loud for me to be using it continuously. I’ve been using an airbrush compressor to clear aluminium chips for a while with varying degree of success.

First, I picked up this mister but it was an absolute disaster. https://www.amazon.com/Coolant-Lubrication-Spray-System-Milling/dp/B01C74DL98/ref=sr_1_6?keywords=cnc+mister&qid=1570450669&sr=8-6

Adjustable arm is so flimsy that the nozzle would almost never stay in the desired position and I could never properly adjust the air stream. What a waste of money.

Secondly I picked up this mister, and it was a huge step up in quality, despite still being a cheap unit. https://www.amazon.com/Deal】OriGlam-Coolant-Lubrication-Cutting-Engraving/dp/B071DXGGP4/ref=sr_1_2?keywords=cnc+mister&qid=1570450669&sr=8-2 Arm is much more sturdy and the nozzle works so much better. Fantastic with regular air compressor and was giving nice gentle air stream (lol cant really call it a blast) when paired with the airbrush compressor. Not what I was hoping for but sufficient to blow the chips off.

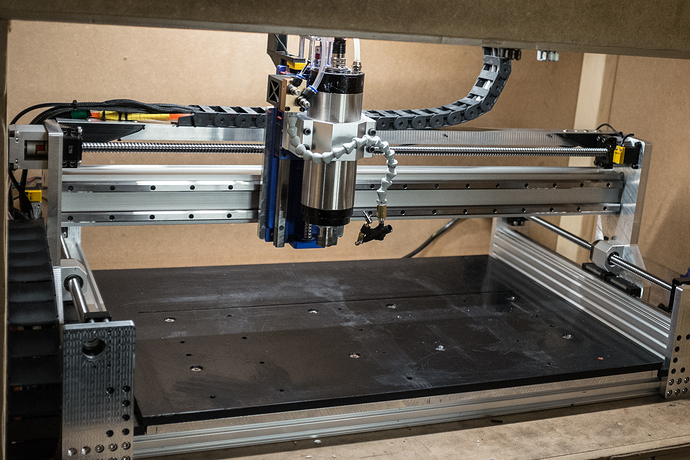

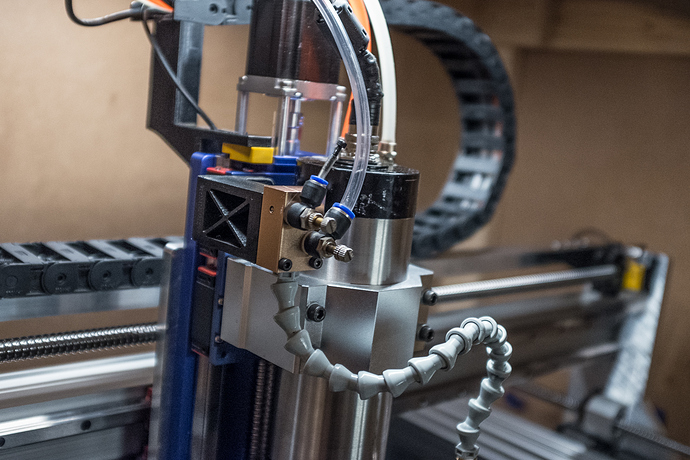

Finally this is the setup I settled on and I’m very happy with the quality and price.

Using this compressor -> https://www.amazon.com/PointZero-Airbrush-Dual-Action-Guns/dp/B010TQCOEE/ref=sr_1_12?keywords=airbrush&qid=1570451163&sr=8-12

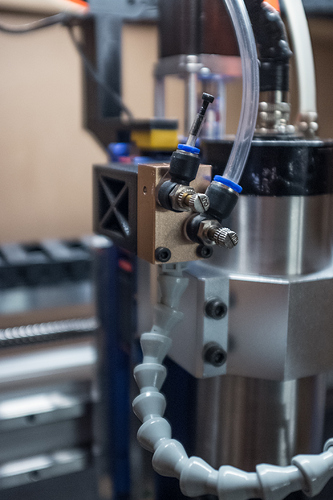

Had to cap the coolant hose with an m3 bolt to prevent the air pressure from escaping the system. It’s just a temporary solution.

Gray mister from a second link was connected to the air gun that came with the compressor using 1/8 coupler available at HomeDepot.

Had to tape the gun trigger to keep the air flowing continuously…

Already tested that setup and it’s doing a great job. Plenty air, quiet, not very expensive . All I have left is to extend the coolant hose. It’s a 4mm OD tube. Once I’ll be able to afford my own shop and won’t have to worry about noise I can remove the paint gun from the mister and hook up a regular compressor but for now this is a great setup for me.

Hope it helps.