It’s possible, I haven’t tested the flatness of my normal wasteboard to try and isolate the problem to the vac table. I’ll be trying that next

Not everyone has a slab of stone countertop material laying around but I do. If you had a scrap that has a pretty level surface. You could attach a dial indicator (see Winston Moy on youtube) and see if your rails were causing your variations. I use a stiff nylon brush to clean my v wheels and a fine scotchbrite (white) non woven sanding block to clean my alum rails. It is possible you have some buggers on your v wheels and/or rails but that is doubtful that they would be big enough to cause random variances but it is possible. You have tried everything else. Make sure after cleaning your v wheels that you make sure they are snug and not loose. The proper method for tightening is to loosen the bolt and place a wrench on the eccentric nut and turn until your v wheel quits turning. Then hold the wrench in position and tighten the bolt. If you do not hold the nuts the bolt will cause your eccentric to be out of adjustment because it will move it. You should be able to slowly move your gantry front to back and be very smooth and your z axis side to side quite smoothly. If you go to fast you will be EMF feed back in the stepper motors and they will sound like you are losing belt steps. So go slowly and smoothly. If you find any hard spots take a look at what is causing it. At the very extreme ends the belt clips can be mis adjusted and cause the gantry and Z axis to not move all the way to the stops. The belt clips are similar to the v wheel eccentric nut in that you have to hold the belt clips with a pair of pliers while tightening your bolt or the bolt alone will twist the belt retainer and cause it to get in the way of the v wheel.

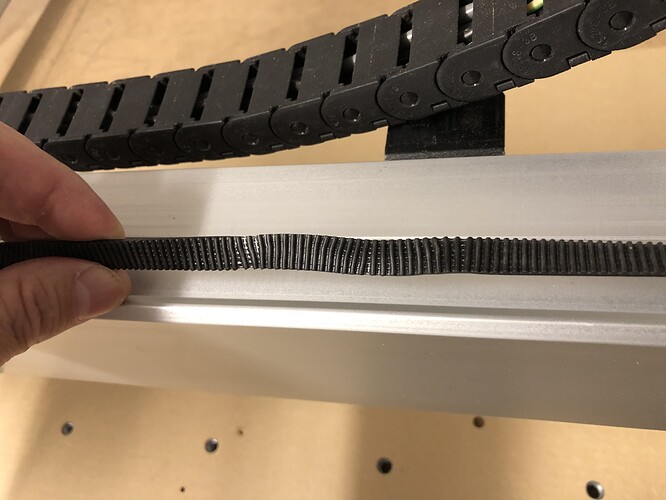

Now I’ve just noticed this. What on earth did I do to make this happen? It’s the X axis belt. I’ve watched the vids on belt tension and didn’t think I had mine overly tight.

Have you ever had a machine make you want to just step in front of a bus?

I also replaced my vac table with a wasteboard, resurfaced it and it seems a little better. Now about 0.2mm differences but still no pattern to it.

You probably did nothing wrong, sometimes after a while belts decide they have had enough, or maybe they had a manufacturing weakness in the first place. Anyway, contact support@carbide3d.com with those pictures and they will take care of it.

I have seen the exact same failure on the forum from others. Time to change belts. The other failures I remember were steel core belts. After you replace your belt would you see if a magnet sticks to the end of the belt. There is not much steel but a small piece will stick to a magnet.

I have steel core belts and was asking on the forum if I should proactively replace mine.

Yep,

Those look like steel reinforcements where they’re sticking through the rubber in the pic. That just happens with age and number of flex cycles with steel cores.

The standard Carbide fibreglass or the kevlar cored aftermarket both last a lot longer than the steel on the pulley size in the Shapeoko. I keep at least one axis worth of spare belt with my machine parts. I suggest you replace all three belts if they’ve got to this age point rather than waiting for the others to fail.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.