I get what you are saying but I’m not sure how to setup the tool paths manually and what type I should use etc

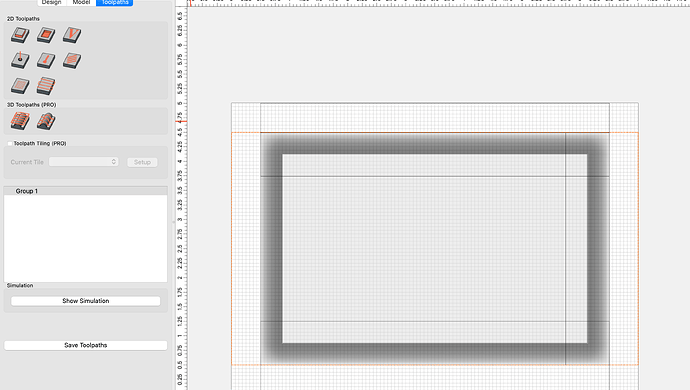

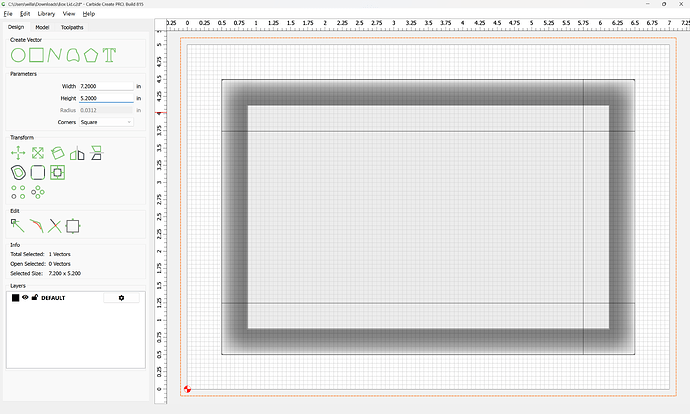

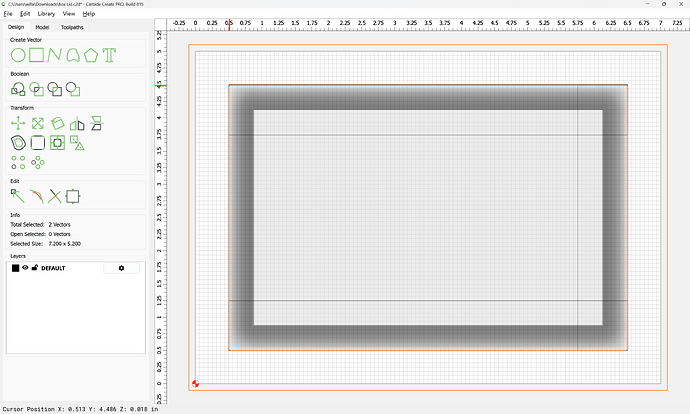

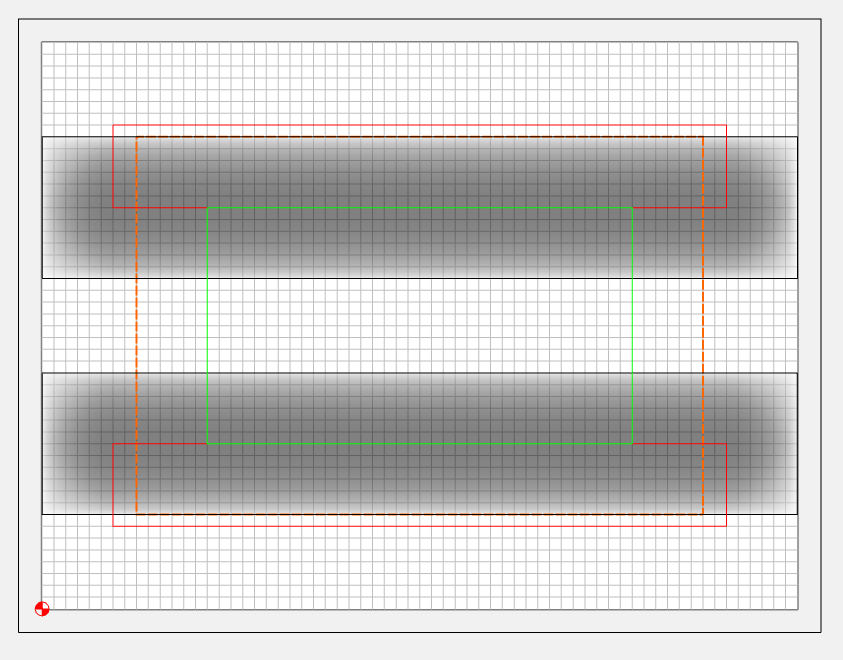

Create a rectangle as shown, the rectangle tool path is layed onto your workspace just as you already have it? Create the second one as shown.

The tool path is no different than if you were cutting out your square to the dimensions you provided above? Just stretch the square to a rectangle as in the illustration I provided. Make another 90 deg from the first.

I know you is said you were short on time but you really should cut on a practice piece.

I afraid I can’t help much more without actually being there.

OK I think I did it right but it is saying 71 minutes to rough it in each direction and an additional 10 and 11 minutes to do a finish Toolpath. Also the

Box Lid.c2d (184 KB)

curves look weird at the top on the preview

Yes, your concept is correct. Cut the 6” or long side first then the 2nd toolpath cuts the 4” side. I’m not at my computer to look at your file unfortunately, not sure why your cut is so long? Are you cutting the lid in 3D or 2D?

I believe the technique being suggested is the one from my link.

What Roundover tool would you like to purchase and use?

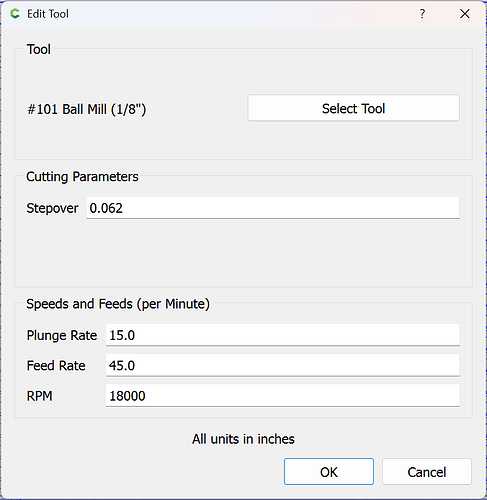

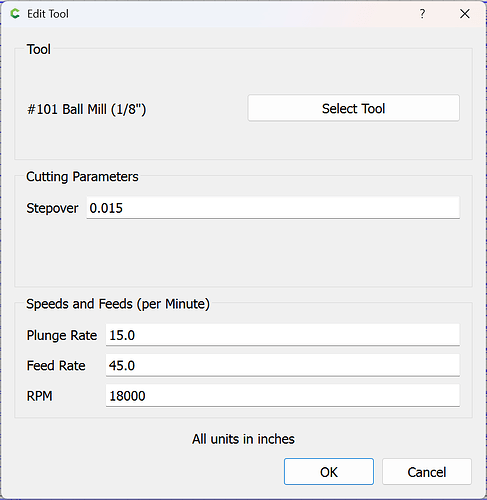

Change the stepover:

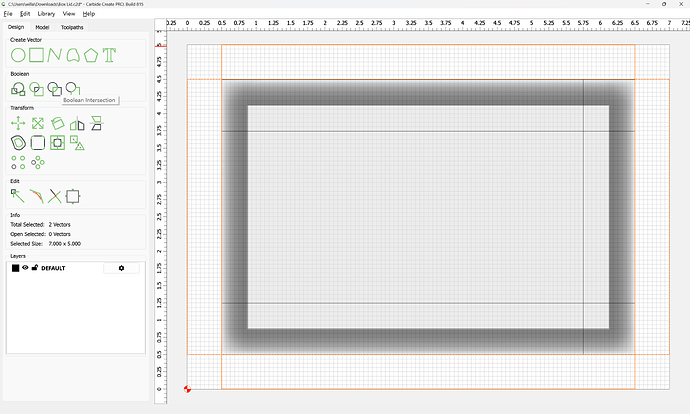

Also, you shouldn’t need multiple 3D Roughing toolpaths for a single model:

Also, is it really necessary to remove over half the material? Why not bandsaw the stock in half and get two parts rather than converting more than half of it into sawdust?

can I rough it with a 1/4" flute and then use 1/8" ball nose for finishing pass ? Just wondering as Ive never done the rough pass or finishing pass before

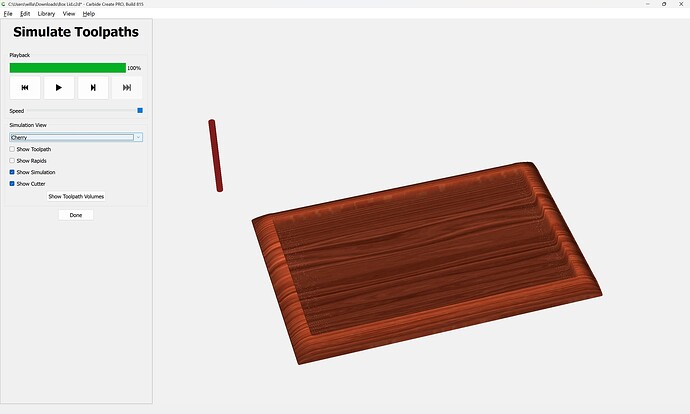

Not understanding what you mean? I want the lid to be a solid piece for a box I am making the pocket is for an inlay I am going to put in the lid. the pocket should be at a maximum of a 1/4" depth but I may make it more shallow to 1/8" depth

Yes, I thought that was how your file was set up.

A post was split to a new topic: Round over or Ogee shapes

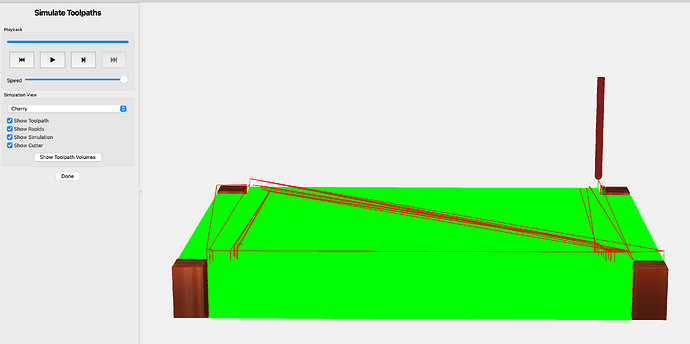

I dont know what Im doing to be honest Im basically messing around with the software trying to figure it out and when I tried the roughing the simulator shows nothing like how it should look so something is wrong but I dont know what.

When I go to the Model tab it looks right but when I go to tool paths it looks nothing like it.

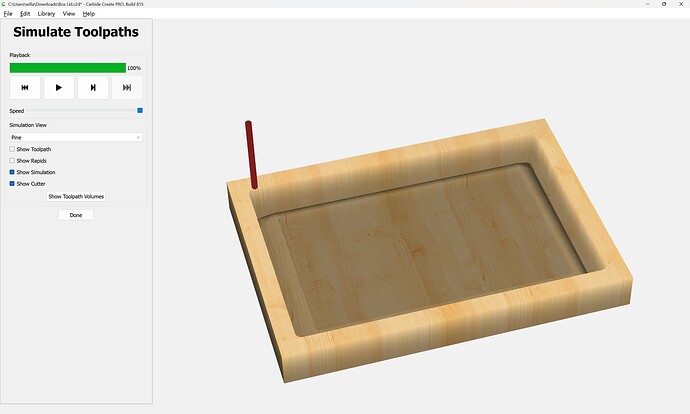

That is what the 3D toolpaths which I show show (modulo the uncut surrounding stock).

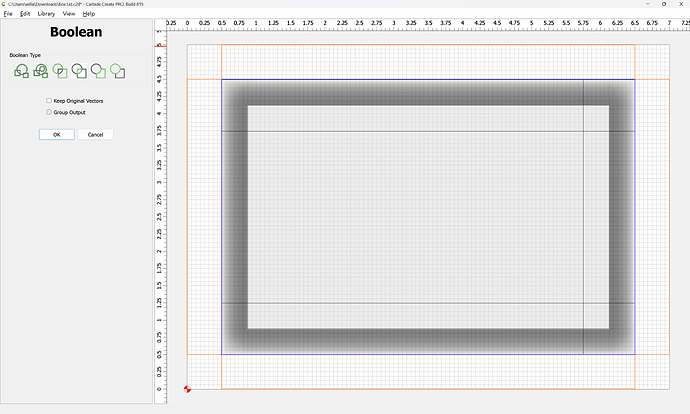

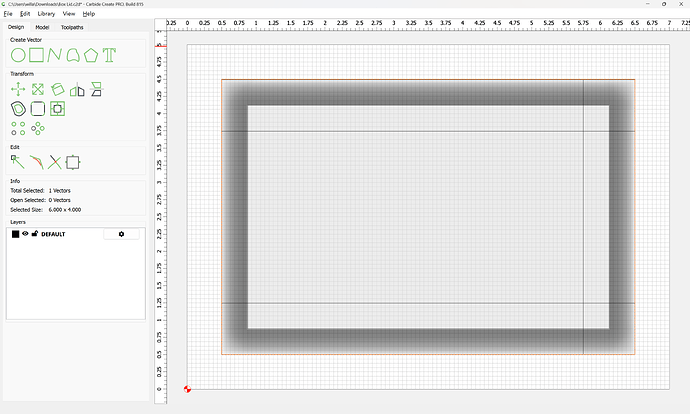

If I then add geometry to cut away the surrounding stock:

then the simulation is much the same, albeit one may see some tooling marks:

So I am doing a roughing tool path or finishing ?

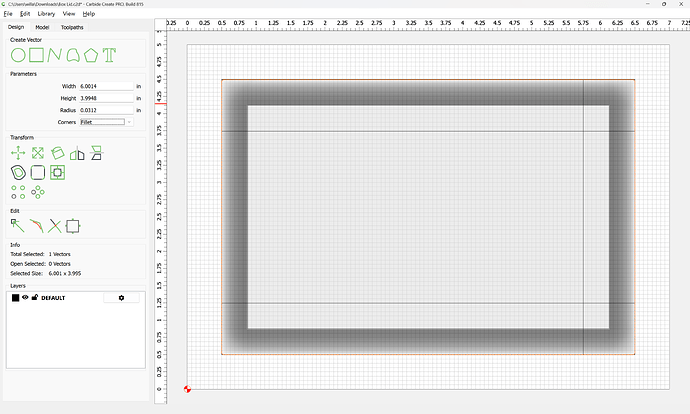

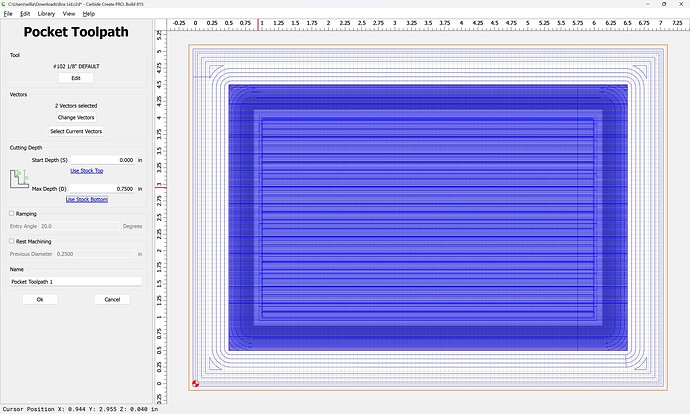

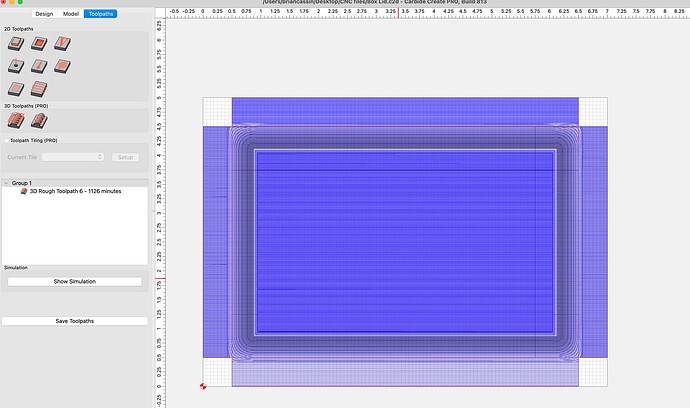

I tried to select just the two rectangles and every time I set it up it looks like this as I have 2 vectors selected and now its showing 1126 minutes…

What am I doing wrong ?

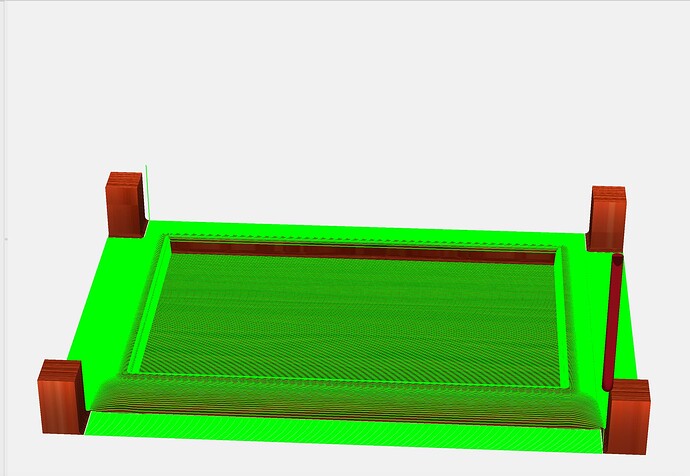

Ok I set the 1/8" ball end mill and set it up now the simulation looks correct and its only 53 minutes

I don’t think this can be modeled together accurately. If you want a true intersecting radius you would need to do it in two steps. Cut the left & right edge past the ends with one set of toolpaths, then cut the top & bottom edges the same way. You’ll have to do this in 2 files.

The selected orange rectangle is the finished part size. The large outer rectangle is just for simulation to cut around the finished part for display. The 2 black rectangles for building the 3D model, the red rectangles for machining the top & bottom radii, and the green rectangle for the pocket. My model components are round, 90° angle, 0.750 height. To get a full radius as mentioned above, I made the rectangles 8" x 1.5"

Repeat the process with the left & right ends in a new file to cut the rest

One thing I thought about, how do I ensure the item is actually cut out of the wood if it’s off by .02 or so, i.e. I set it for .75 height and its .77

If you’re Z zero is on top it shouldn’t matter. It will be .02 full on the bottom.

If it were quite a bit shorter it might be a problem.

A trim / profile path would need to be bumped up to 0.77 or more to cut through.

Well something is wrong, just tried running the job and it buried the head all the way to the bottom to run the job. I used my bit zero and manually set Z zero by the piece of paper on the top of the piece method.

I think this machine has something wrong with it. This is why I haven’t used it in a long time. Every time I run a job something goes wrong and it doesn’t behave as expected