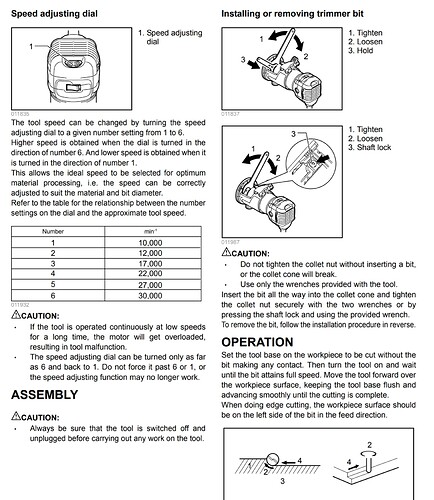

I have a Makita RT0700 router in my Shapeoko 4. The speed options are 1-6. What would that be in terms of RPM’s?

FWIW, I have mine permanently on 3+ to get 18.000RPM, and only use that, adjusting the feedrate as required to get the desired target chipload. My reason is that even though one should ideally max out the RPM to minimize cutting forces, I really can’t bear the screaming of the Makita at full 30k speed for long periods of time, and 18k is where my noise threshold is (with the muffling from the enclosure) to comfortably sit at the computer by the machine for hours.

Thanks, I’m engraving text and symbols on hard acrylic (painted), I can’t go too fast here otherwise the acrylic will melt and stick to the bit… Thanks for the tip on other materials and I do need to get make an enclosure…

Just a quick word on this, for your consideration. What plastics don’t like is the heat that may accumulate locally from the cutting action, but this does not necessarily mean that one should minimize the RPM. This was one of my initial thoughts but a long time ago @gmack set me straight, I tested myself and became a believer (that what matters in plastics is to feed fast, even faster if spinning fast too, but that one could get a perfect cut in plastics at 24.000RPM too…). Numerous tests later I still increase the feedrate (a lot) whenever I see signs of melting, and this always works. Bottom line, plastics require high chiploads, whatever the RPM/feedrate combination is selected. It’s also a good opportunity to see the machine operating at 200ipm, which does not happen every day when cutting wood or metal ![]()

Thanks for sharing this and it makes sense. I will do some testing with the feed rates, so far I’ve been using the standard feeds that come with the bit-settings. I’ll give it a try!

I’ve tried faster feeds up to 180% and for vectors it went great, with mono-text about 160%, no problem. Thanks for the tip!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.