Thought I would share the Shapeoko 3 XXL enclosure I am working on as it unfolds. My Shapeoko is scheduled to arrive tomorrow  , but thought I would get a jump on the enclosure.

, but thought I would get a jump on the enclosure.

My primary goal was to design something that I can use indoors (I hope I dont regret this). I am out of room in my garage, plus really dont like the idea of the Shapeoko being in an un-climate controlled space (southern high humidity, and cold winters). So sound and dust resistance is a high priority as you can imagine. Also, I have limited space in the room I am putting it, and wanted to optimized things by incorporating a workbench on top of the enclosure.

I started with this as the basis of my enclosure. Its a Hopkins 2x4 Basics Workbench. It includes the black supports, you just provide the lumber. Its supports a footprint of up to 8’ x 4’ (or smaller).

I started out planning to put the CNC on top, and building an enclosure around that. But then I realized that if I skipped the middle shelf, I could put the CNC on the bottom shelf, add walls, and voila, a CNC enclosure with workbench on top! Not the most ergonomic design, but with my design goals, I think it will work out well.

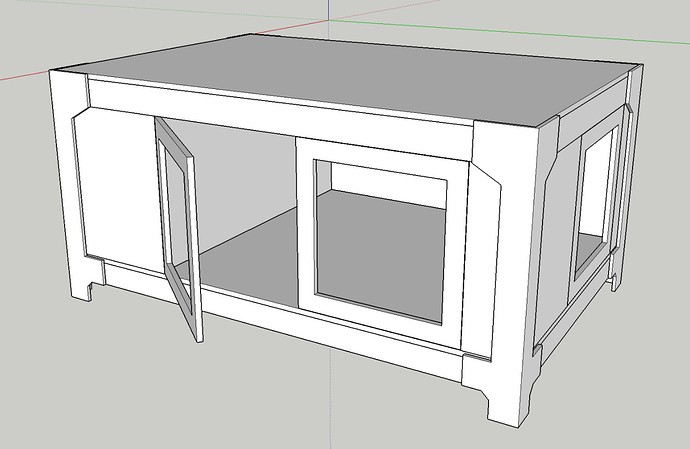

So I whipped up this CAD drawing with my ideas:

The total dimension is 6’ W x 4’ D x 36" H. The lower space for the CNC is 54" W, 47.5" D, 27.25" H. The remaining fully enclosed area on the lower left is for a wet/dry vac and Dust Deputy.

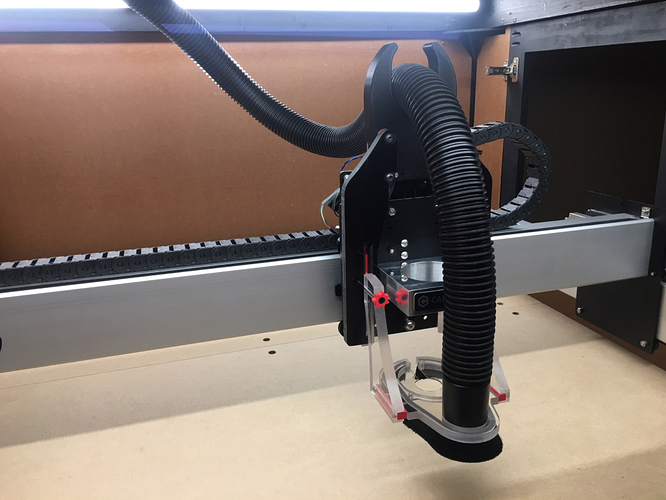

So this weekend I got starting putting things together. I cut all the 2x4 and 2x6 lumber, and 2 sheets of 3/4" MDF. I painted the lumber black, and did 4 coats of poly on the MDF. This is the result:

I was impressed by how well it turned out. Almost seems like it should go in the Kitchen, not a used as a CNC enclosure!

Next steps are to begin working on the panels and doors to enclose the bottom, then work out where to mount switches, buttons, vacuum ports, etc, and how to route it all.

Anyway. Hope some gets ideas from this as I progress. And please, feel free to give me ideas and input!