Why does the topic proclaim that it has been Solved?!?

I thought I was going to be writing about how well things have gone, but that is not possible. I still cannot create reliable double-sided (flip) parts.

Our project is complex, with 5 major parts designed in OnShape, 2 of which are large 3D prints (20 hour prints with over 1 lb of filament each) plus 3 wooden (maple) CNC parts. The complex shapes (which need to match each other) are generated as STL files and run through MeshCAM for the CNC. I know of no other way to process STL files into CNC at a reasonable price. We started out using MeshCAM’s flip feature, but gave up on it and are now using two separate job sequences (for top and bottom). Since we CAN get perfect parts, we do not doubt the general approach we are taking.

Our general approach for the CNC parts is to create a series of registration holes (for dowels) in the Y direction on the waste board, with a well-defined center (Zero) point. The center of each stock piece is placed at the center of the registration holes, and 4 CNC passes then take place. The stock is held in place using 4 side clamps, and the outside of the stock is never removed. The top roughing and top finishing passes create the top half of the part, along with the top half of two registration holes. The part is then flipped top-to-bottom (around the X axis, not like book pages) and dowels hold it in position, with the side clamps used again. The bottom roughing and bottom finishing passes are then done.

We did this repeatedly using cutoffs from a spruce 2x6 for testing and then tried to make the final parts using maple.

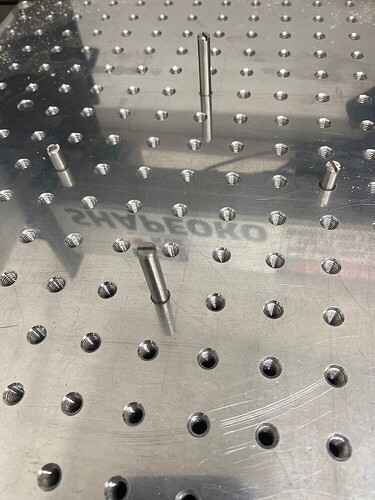

The typical failure mode is that the two top passes do not register with the two bottom passes. There are shifts, usually in Y, but recently in both X and Y. A typical Y shift is 1/8”, as is shown here with a 1/8" drill bit.

We use a 1/4” end mill for both roughing and finishing most of the time, with a 1/8” bull nose for finishing some of the parts. The 1/4” end mill stays in place for the first 3 out of the 4 passes, and sometimes for the 4th pass. The tool is “re-loaded” at the start of each job/pass (really just re-registered).

Some of the problems were due to the drive gears on the Y steppers having loose or missing set screws, but that is fixed. The machine is mechanically solid, at least to me.

I made the mistake of trying to adjust the Zero in the middle of a series of runs, which explains some of the problems for those runs. I now set the Zero in a specific place (and write that down) and ensure that ALL of the passes are made with that Zero (except for adjusting for stock heights).

I now re-initialize the machine just before every run, so at least 4 times for each part.

We made one near-perfect part out of spruce on Monday night, but after that, none of the maple parts were correct.

I have observed some savage changes in Zero after some runs, perhaps as much as 1/4” in X and Y. The Zero is the middle line, so the end mill is off by 1/4".

There have been at least 3 crashes, where the end mill was wrenched from the collet, usually do to user error (wrong Z Zero). The end mills run true, visually, and that one perfect spruce part was made just a few days ago, so the router and end mill are probably OK. The router occasionally stutters, as if it would like some new bearings, but it created a perfect part two days ago.

Possible causes?

-

MeshCAM could be generating code that challenges the machine too much (it is on the hard wood setting for feeds and speeds). I hear occasional loud cuts where the router RPM falls a bit. Carefully monitoring the process for 8 hours is exhausting, and even if I hear a challenging cut, I have no way to correlate that with the NC files. I suppose I could run over and find what line Carbide Motion is on, roughly, but I have not done that.

-

The machine could not be strong enough to withstand the cuts, resulting in lost steps. It appears to be fine, but I could be missing something.

We considered running some tests, but with some runs taking almost 2 hours, a 2 minute test is unlikely to be useful to us. If the machine is slowly losing Zero, a 2 minute test will not tell us much.

The major issue is that we cannot produce parts repeatedly. The fact we are able to produce a perfect part suggests the issue has something to do with the Shapeoko itself. The varied results could indicate the machine doesn’t maintain a reliable Zero position.

This is the latest failure:

At this point, the entire process is unreliable. There is no way to predict if a part will come out correctly or not. Extremely frustrating, and I am ruining a lot of stock.