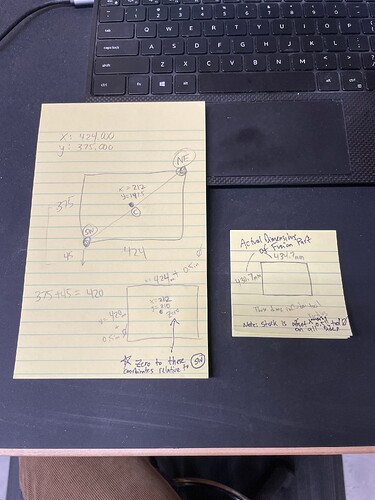

Thanks to the help from @wmoy and other in the Carbide community I was successfully able to flatten the bed on my Shapeoko 4 Standard after some careful planning. How I did it: I used Fusion 360. I measured the “usable” bed area by using the rapid positions for the SW corner measuring the diagonal to the NE corner. I added additional travel in the front of the bed to make sure to machine the slats all the way to the front. I created a Model that was these X/Y dimensions minus 1mm on each side for margin. I found the zero of this rectangle (which is NOT the Center rapid position…it is closer toward the front of the machine). For the Stock in Fusion I made it 0.5in smaller on each of the 4 sides of the Model to account for my tool radius (a 1" surfacing bit). This ensured the cutter would fully cut the corners and not leave a radius. I made sure to zero my X/Y at the center of the rectangle for the cutting area (again, NOT the Center rapid position). I machined with 0.5mm depth of cut for each pass. The code is setup for 2mm total depth, but I ended up ending the code after 2 passes because the bed was already flat (confirmed by using a straight edge crossing multiple slats). Hopefully this will be helpful to someone else out there! ![]()

My scribbled notes on figuring out the dimensions: