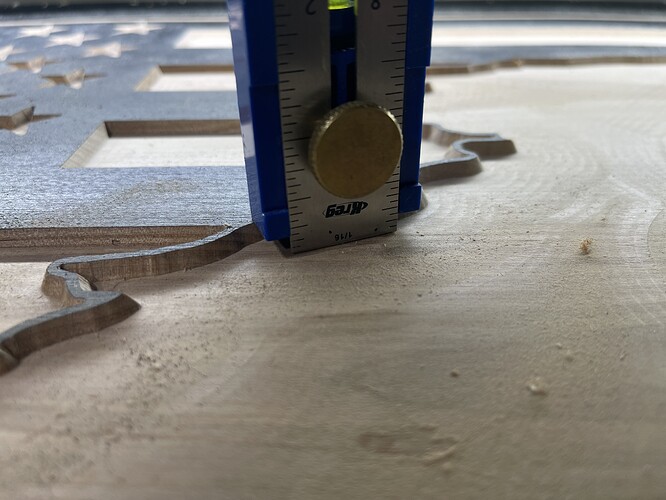

I’m having trouble with my machine cutting quite a bit deeper than I want. In the end the result looks ok, but isn’t ideal. I’m setting the max depth on an Advanced V Carve of .1”. Starting with a 1/4” 201 and finishing with either a 60 degree V or a 30 degree V. The actual depth of the cut ends up being about 3/16”. Maybe a bit more. I can’t figure out what to change or what might be causing this. Any help is appreciated!

is the machine properly calibrated recently?

I’ve only had it a few months. Movement seems normal. Should mention I’m also using the bit zero. How do you calibrate the depth?

A Shapeoko 5 Pro would not need calibrating.

How deeply a given toolpath cuts will depend on where the origin is set relative to the surface of the stock and how flat the surface is, and how true that surface is to the plane of the movement of the machine.

I would suggest trying a test cut in a stable material such as MDF, first surfacing the stock, then cutting a test pattern such as:

Thank you, I’ll give that a try. Would/could it be an issue If the following.

- I tell carbide create that my piece is 1” but really it is say .85” thick

- I tell it to start at 0 and cut down .1”

- I use carbide motion to probe corner

- I send it to cut

Would that cause any issues? I know that cut through would be an issue as it isn’t 1” thick, but the .1” should still be accurate correct? It is proving the top of the board so I would think that wouldn’t be an issue but thought I would ask.

Precision has to start somewhere, starting from a flat, accurately measured and accurately placed relative to zero surface is pretty much essential.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.