Not sure why I can’t get the XXL to center on the stock. CC shows design center on the stock but when CM executes the gcode its off to the left. Settings are configured for lower left corner.

Found my issue … senior moment … not sure how my dimensions changed in the settings. Stumped.

Please post the file and provide a step-by-step of:

- what you did

- what you expected

- what actually happened

I give up … changed the dimensions and now lost all the design that I spent hours on.

Revisited … still stumped.

- Stock is 6" x 6.75".

- 6" x 6.75" rectangle box drawn on CC.

- A heart shape is aligned to the center of the rectangle box.

- Gcode (heart shape) generated.

- CM, heart shape loaded.

- CM, machine homed.

- X, Y, & Z offsets cleared and zereod.

- Gantry jogged to left corner of stock, using rapid position.

- Touch probe placed on top of stock, including the touch probe lip.

- X & Y zeroed respectively using the CM probing command. 1/4" end mill installed, #201 selected in CM.

- Z zero manually to top of machine bed.

- Bottom point of heart shape off centered to the left. As measured, total stock width is 6". Center point of heart shape measured 2 13/16" from left of stock.

Still can’t figured out the issue.

Other attributes … J Tech laser installed, using Light Burn software. Light Burn software has a gcode command to switch from CNC to Laser mode. This is done to reverse the direction from negative to positive value.

Light Burn has been previously running with CM with no issues until recently (this post).

If you start at your X0 and jog 3" to the right, are you 3/16" to the right of your heart point?

Neilferreri,

Here’s another approach I did based on your question.

In CM, I entered G0X85.8012F100 or 3.378" from left of stock. Vbit zeroed at the corner of the stock.

X axis moved 81.53mm or 3.209" from left of stock.

A difference of 4.2712mm or 0.1682" short of target 3.378".

$100=37.9mm

So now I am stump … I reset the default value for $100=40, entered G0X85.8012F100 and guess what, I am back on center.

What gives, I calibrated for belt tension using a value of 125mm, checked the distance after inputing the new calibrated value (37.9mm). Now the default value is on target and the previous calibrated value is off.

Your thoughts …

Belt shrinkage? ![]()

How’s your belt tension?

How were you measuring when you did the calibration?

There have been discussions about the belt driven machines needing different step/mm values for different distances and even different machine positions.

Belt shrinkage = temps in the house is constant … AZ %Rh is pretty constant. Belt feels good and tight.

Calibration: secured a digital caliper to front of machine bed and within same position as where I normally place the stock. Caliper zeroed; but at rest on one caliper jaw; midi command travel 125 mm on either X or Y axsis; closed caliper jaw; record 3 readings; average readings; input new values for all 3 axis; validate new adjusted values for a travel distance of 125mm. Note caliper stays fix during calibration therefore, zero reference is constant.

I wouldn’t know for sure. It just sounded like a steps/mm issue in your original post.

Hi @GIban671,

I did not quite follow the full story, but just wanted to share that I have never seen myself a calibrated belt value that is so different from the default 40 steps/mm value: when I calibrate my belts, I usually end up with a value that is typically between 39.9 and 40.1 (and often much closer to 40, like “39.92” or “40.07”).

Which makes me think that your calibrated value of 37.9mm may not be correct, for some reason. That’s a 5% correction factor (that you end up seeing as 5% error on your move, e.g. 81.53mm versus 85.80mm), as far as I am aware belt stretch cannot amount to such a large error by itself.

When you calibrate, do you start the process with $100=40 or a previously calibrated value maybe ? Is that result of 37.9 steps/mm repeatable ?

Not 100% sure, but I believe I did restart from the default values.

I am stumped and confused or perhaps another Senior Moment. This Newbie hobby has been Great but comes with a lot of oops.

So I recorded my first calibrated values:

X 38.98635

Y 38.93475

Z 40.22459

Checked at 125 mm, GOOD

Retightened the belt after several hours of usage, I guess it’s call the break in period.

New calculated values:

X 37.99777

Y 37.9449

Z did not redo

Wasn’t happy with the calculations and actual measurements, so I manually trial and error values and checked against a measured distance with a caliper.

X 37.9

Y 37.84

Z did not redo

Validated these new values and all checks ok.

Going to redo the entire calibration, reset to default values and then see what I get.

I’m quite surprised that the values would change that much in a few hours (and that they would be below 39 steps/mm after the first calibration already) because I hardly ever tighten my belts, and keep getting relatively precise dimensions.

Just to check, when you say you checked at 125mm after the calibration and it was good, did you measure that using the same caliper process, and without having moved the caliper since the calibration measurements?

If so, a better check could be to move the caliper elsewhere, and recheck. A possibility I can imagine is if the axis of your caliper during the calibration was not 100% aligned with the natural axis of the machine, then you would measure a slightly longer or slightly shorter distance than what the machine has actually travelled. And you would still read a perfect 125mm after calibration, because…the calibration factor would have included that skew. From experience, it’s not so easy to attach the caliper such that it is perfectly aligned with the machine axis, so who knows…this is just a guess.

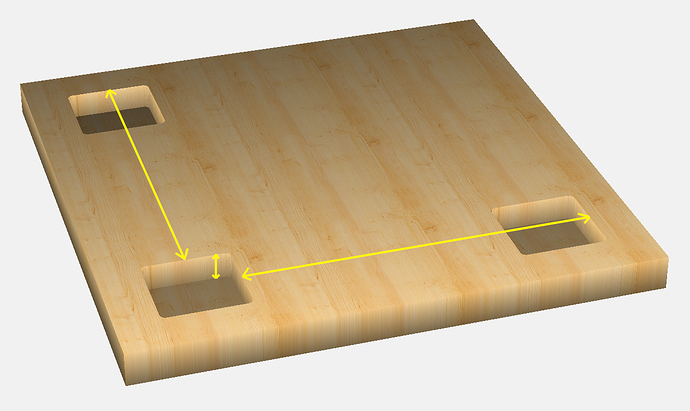

You could also try to measure the calibration factor using a different method, and see if you get the same values? For example, cut three pockets far apart but aligned along X and Y, and measure (with a ruler) the actual distance edge to edge:

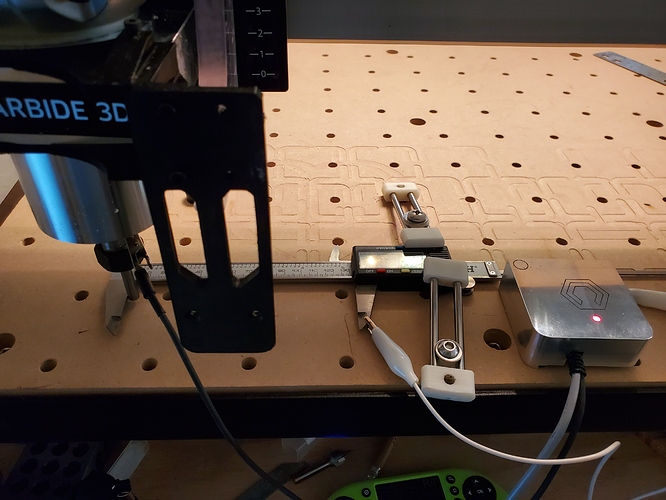

Yes, I attached a pic of a setup I use based on one of our members setup using a dial caliper.

The caliper is aligned using the holes on the waste board. The holes were verified to be running parallel to the X axis and Y axis.

The caliper did not change and is at a fix position to avoid the uncertainties of cosign errors.

I use the touch probe to show me when the inverted router bit touches the caliper jaws. Also the Z axis is dropped down to the same depth using the rapid position plus 6mm of manually moving the Z down.

Mmh. I have no clue then, these values and their variation seem weird to me, but I don’t have an XXL either so maybe other XXL owners who have calibrated their belt stretch could comment whether they have such low (38-ish) $100 params…

Did you have a fresh battery in the caliper ?

Unless someone has a better idea, I would advise to do the three-pockets method, see what value comes out, in the (unlikely) event that something in the caliper setup is wrong

So 125 mm at default value of 40 mm resulted in a measured distance of 131.26 mm.

With a new calibrated value of 38.09234 mm resulted in a measured distance of 125.45 mm.

As in my previous calibration, not being satisfied with 125.45 mm, I tweaked the coefficient value by trial and error till I got 125 mm. Only this time I will not till I can find the root cause of why the default values have a deviation of 5.81 mm.

I have an uncertified 123 block that I can use as a go/no-go reference to check the accuracy of the Chinese Caliper.

1" = 25.43 mm

2" = 5.083 mm

3" = 7.629 mm

Looks good …

Yes I am stump …

Interesting discovery:

From the SW to the NW, the X axis deviates by 0.5". Looking for the fault.

EDITED: Correction Y axis is not tracking parallel.

X axis is tracking.

Belt tension sounds good on both sides of the rails.