Any problems with that VFD?

None yet. I have a 10 hour cut I’m planning to start tomorrow, so we will see how it’s working after that.

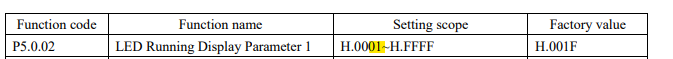

Since your VFD reportedly shouldn’t be locked down, you should be able to set P5.0.02 to 0860 to enable the display of Torque, Power, and Speed as shown here.

I have mine set to 0861 as you can not set the last bit to 0. Output torque is in percentage, power is in kW and speed is in RPM.

OOPs - missed that - thanks - you always get frequency too then? You know that the display can easily be located away from the VFD for easy viewing/recording right? Lucky you! ![]() You can easily see how hard you’re pushing the spindle and machine, when things are deteriorating, as well as easily vet speeds and feeds calculators like Millalyzer.

You can easily see how hard you’re pushing the spindle and machine, when things are deteriorating, as well as easily vet speeds and feeds calculators like Millalyzer.

Yes, frequency is always one of the display views.

When I first got the machine and after I got the missing parts and broken limit switch replaced support was screwing with me about how they can’t help me because “they don’t support 3rd party anything” and “it works fine because it moves” and “how do you know how it’s supposed to work” I asked them the same thing on the phone about how i just return the whole thing. This is when I thought it was just my machine and I got a lemon and it was clear I was on my own.

I was told I would have to pay for return shipping and also pay a restocking fee, and it would only be refunded after it was inspected and approved. I don’t have to tell you how much it would cost to ship 2 oversized boxes that weigh over 100lbs across the country along with a restocking fee that is a specific percentage of a 5000 dollar order…

Once that machine arrives it’s your new baby, your responsible for it for good expecially because they don’t think anything is wrong and neither support nor sales knows much about how it’s supposed to work in the first place.

This is simmilar to what ive accepted with my hdm. Once anything electronic fully dies im just using a grblhal2k i have and ordering clear paths + new spindle and vfd. Unfortunately its the only way to know all the settings and everything im running is the standard and not mixxed with firmware or hardware juice.

You wouldn’t even have to really replace the VFD and spindle until it dies, you just have to gut all the stuff that carbide added in that box that’s getting in the way, unless that burns up.

Those 750 dollar spindle kits they are selling are the cheapest of the cheap low bidder back alley Chinese factory stuff. The ones where they don’t even try to make up a name for branding and just sell everything white label.

I’m not sure who designs the “Warthog” board or the “Spinderella” board, when they will graduate from school or how hard the people at whatever factory laugh as these roll off the assembly line but I can tell you all the stuff being talked about here and elsewhere on the internet is no laughing matter.

This is what the shop literally says, among other things that are funny.

Good Vendors - Nope

Testing - Nope

Safe! - Only if you consider it spinning up full speed without notice safe

Plug and Play - Well it does plug in…

Derp.

None of that works if the 5 Pro controller is the problem, which I suspect is the majority of the problem. Have you bought a different spindle or just crushing nuts here???

My spindle works fine now since I was able to bypass the added carbide nonsense and use the standard output of of the ICSP header that is tied to the spindle control pin. Now it just does the spin-up when powered on and connected because clearly someone forgot to put a diode in the correct place and didnt use pull down resistors in their newly found octocoupler hysteria. The Arduino platform isn’t rocket science, unless you start adding poorly designed rockets to it.

The spindle I have was known good and in use before this mess. But clearly come to find out that not only are there problems with the controller hardware on an engineering level, including their thermal budget for the stepper drivers but also the “adapter” boards that they have to use because of the previously mentioned design flaws.

So no, I’m not just “crushing nuts here”.

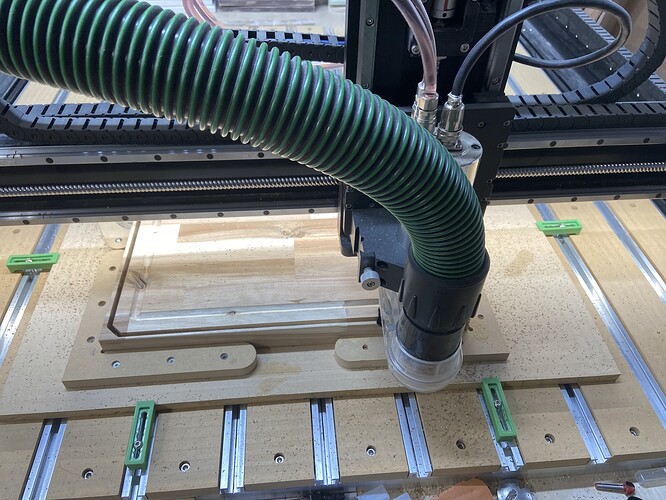

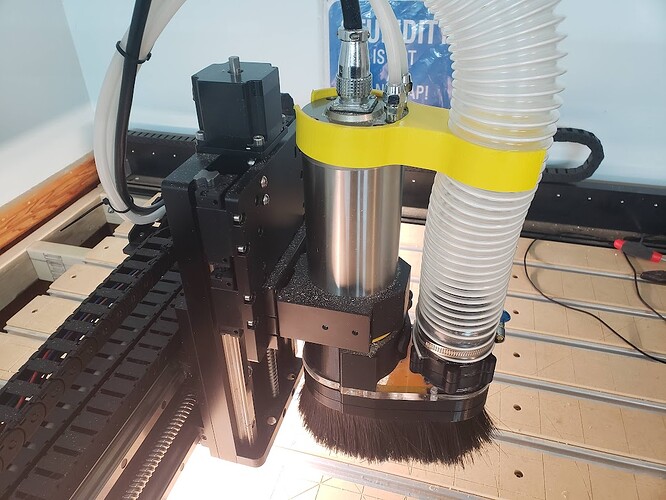

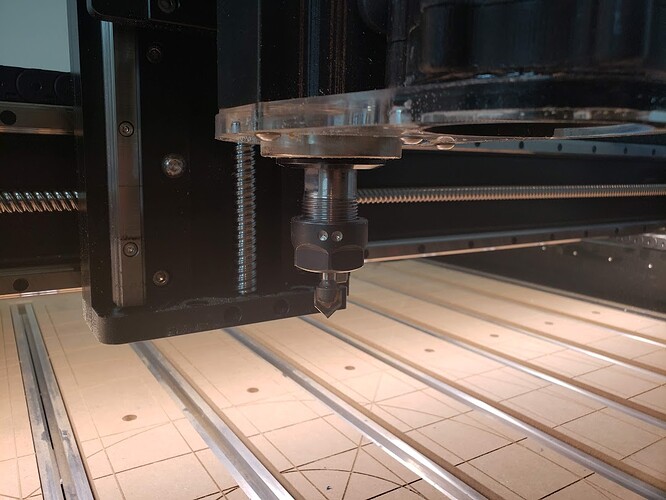

my spindle is a 80mm 220v 2.2kw water cooled one with ER20 collet.

Spindle

Business end

The 80mm mount for it had to be gotten from PWNCNC along with the dust boot.

Carbide doesn’t offer an 80mm anything in the terms of mounting for the new Shapeoko. But mine now sure works amazing except for the surge if the spindle is enabled when you turn it on or connect to it via usb.

Beauty. I wanted one, but there was no mount when I was looking. Didn’t know pwn has started offering one. How do you let it rest when you turn off the power? Do you have some sort of cradle?

They were in pre-order for a while but when I went to order them they shipped right away. No cradle needed it doesn’t droop at all when powered off.

That’s odd. Are you sure there’s no power to the stepper motor? If I hit the estop, my z sinks immediately. It didn’t with the router installed, so I figured it was the extra weight of the spindle. I let it rest on a board under the frame.

Nope, no droop at all which I was actually expecting because of the ball screw thread pitch. I have the whole machine on a power bar so there’s defiantly no power going to them.

You might want to lube up your z axis. My SO5 drops at a decent speed with a 80mm 2.2kW water cooled spindle installed. It would drop sometimes with just the C3D 65mm 1.2kW. I’m planning on adding a motor brake.

Not sure what to lube besides the standard maintenance stuff. The machine is basically brand new I just received it about a month ago and haven’t really run it very much because of the problems getting the spindle actually running and controllable by the controller.

When I park it for the night, the next day the z is exactly where I left it.

My machine came bone dry. Lube up the ball screw and rails then run your z up and down. My z did not drop with the 65mm spindle until I properly lubricated everything.

C3D recommends Vectra 2 oil but I don’t think they realize that the tackifiers were removed a while back when they reformulated it and now Vacuoline 1409 is what Vectra 2 used to be. Mobil does not recommend Vectra 2 for vertical rails anymore.