Interesting, mine is definitely not bone dry but I will have to look into what you just said about the oils. I went over all of it when I got it and keep everything oiled well because Im in northern new england and well, rust is the state mineral.

Yeah, the thread automatically closing is ridiculous. Let that sink in. It is ridiculous and makes me feel ‘not good’ about participating.

I do want to mention @WillAdams can re-open it (edit: I see you have found a resolution for your issue), but it is ridiculous that you’d have to even ask…

That’s great info!

Unfortunately it is $170 for the smallest amount I could find (5 gallons)…

For me, once the warranty has tolled I will likely totally retrofit the weak components. The VFD situation really sucks and in retrospect, I should have gone to market for a better solution. Mine on M5 (shut condition) still shows 175ish RPM on the readout. Seems like a bug to me, but support says “that’s normal”. Further, the fact that I can’t override spindle speed from the hard controls on VFD controller seems like a kluge.

This is my first CNC / VFD combo, so I was hoping it would suffice considering prior I hand crafted everything. Jury is still out for me, as I’ve only had it functional a few days now. Now to figure out EMP shielding for it so it’s useful into 2025 ![]()

There’s nothing normal about the spindle still running after an M5 is issued. That’s not safe and you shouldn’t use it until you can get that resolved.

If I were you I would open your own thread about this issue and press it. This is not okay.

For clarity - there is no rotational motion. The RPM sensor in the VFD controller is showing 175ish RPMs though it is truly zero. That just seems a bug. That, support states is normal behavior.

That’s most likely the voltage going to the VFD from the control line I showed in my video above, the VFD must be programmed to ignore anything under a minimum rotational speed. That’s probably why they lock the settings on the VFD.

At least it doesn’t spin like mine did. That’s still not normal lol

Everything feels so hacked together.

We’ve stood back a little from trying to do support over the forum as we can’t track cases. This topic has stretched out.

Yesterday Rob put out a blog post to address the issues we’ve seen with VFD/S5P users.

Please take a look.

https://carbide3d.com/blog/cold-solder-joints/

We’re doing what we can to rectify any issues. Please bear with us and rest assured we’re going to make sure things are working as they should.

@Luke I ordered my Shapeoko August 4, 2023 and it shipped a couple days later . I was told that the spindle spinning to full speed was “normal” by support and Brandon

It still does surge to 100%.

And wouldn’t that be a PULL DOWN resistor they forgot instead of a PULL UP resistor? A pull up resistor would pull the signal to 5v all the time aka full send, a pull down resistor would pull the signal to ground until it was given current aka 0v.

So now what do I do exactly? Open another support ticket? And now I have to worry about the bitsetter? Come on!!

I’m not adding to the support burden here (because I know this is a QC issue,) but this whole episode has shaken me to my CNC core. My 3XXL has been running perfect since 2019.

To be honest, I’ve been perusing other manufacturers to see what viable options I have, because I’ve been looking at the 5 as my newest and last machine. As a tech and past business owner, Rob’s blog post brings a lot into perspective, and I appreciate that. We should all appreciate the open discussion allowed here on the forum, because these kind of on-the-fly comments are truly detrimental to a manufacturer.

To their credit, they’ve not censored any threads that I know of (even the “salty” ones ![]() .)

.)

My initial decision, in December 2022, to hold back on a purchase is still the way I’m thinking … for now.

Please DM me your support ticket reference no, and I will review it.

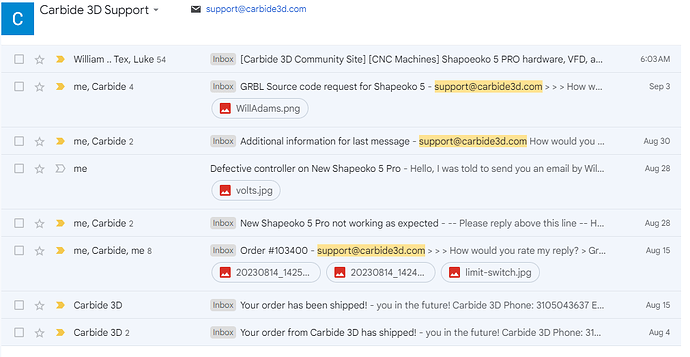

I have no support ticket reference numbers that I’m aware of in the entirety of the communications I have been having with support over email or phone.

Thanks, I’ve found your tickets.

I need to talk to Brandon about this - can you confirm you have our Spindle and VFD?

Noted that in the conversations, I’m seeing reference to a third party brand.

I DO NOT have your spindle and vfd. The output signal of the controller board is the issue. I have posted in detail in this thread. The entire reason I contacted support right after I got my machine was for that reason. I have put both a multimeter and osciliscope on that signal wire, I have posted a video of what that voltage is, and what it does.

Please tell me this isn’t going to go down that path again about how I’m SOL because I already had a fully functional spindle and VFD that I didn’t purchase from you.

We don’t typically support third-party VFDs.

By that, I mean we don’t stop any integration, but it’s not possible for us to support other brands - which might have a different specification or setup process that we are not familiar with.

That said, your electronics should be working correctly - I’m have opened a new ticket and have dropped you an email.

Thanks… I guess… I’m not now, nor have I ever asked carbide to support any third party anything. I’m asking for support on a controller that is not in any way functioning as any controller should function.

The signal leaving the controller should be standard and consistent. It should not matter if I am hooking it up to your spindle or a ham sandwich.

You linked a blog post made by your own company going down a laundry list of issues, admittedly. A manufacturing company that clearly didn’t care in the slightest if the products you ordered got to you in a functional state.

There is an issue here and chalking it off on a spindle that works perfect on absolutely everything else I throw it on because it’s “third party” isn’t at all a great look, and is terrible customer support.

The machine and your spindle VFD kit are two separate products. If they are exclusive to each other that needs to be stated. But I shouldn’t lose support on one product because I didn’t specifically buy a completely different product.

No where anywhere did it state at all that the shapeoko 5 was not compatible with any other VFD besides the one you sell. This is getting absolutely ridiculous.

As above - I’m trying to help you get up and running and check your controller is working.

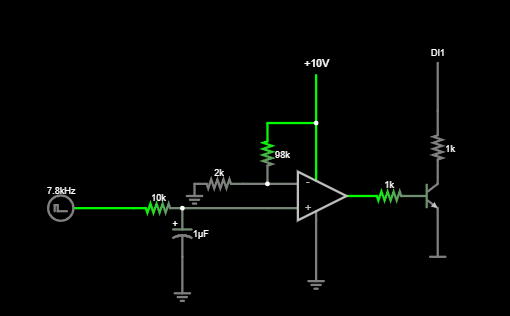

You could set a enable pin that doesn’t turn on until you are at a higher RPM. The enable pin can come from your PWM signal by running it through a low pass filter and comparator with a 200mV trigger that switches a transistor to short digital input pins on your VFD. C3D’s VFD does something similar to pull DI1 to COM on their VFD controller.

This was my solution to gaining a enable pin for my PWNCNC VFD kit. The comparator used in this circuit was a LM324 because it is what I had on hand.

If you really are truly concerned about safety then you should have a dedicated interlock button on your VFD. Even better, power the VFD off and LOTO before touching the spindle(Only OSHA approved method).

Thanks for the diagram. Currently I have the forward enable on a manual switch for when I change bits. It is what it is and an extra step but whatever. It does a full pull on power on and USB/serial connect anyway so it will still trigger the enable pin regardless.

It’s the fact that the controller system on this new machine is either not working correctly in the first place or just a flaming pile of junk. The lack of taking responsibility for either one of those things is staggering.

Even these problems with whoever made the control board in the first place, the backlash from what has happened triggered a giant blog post to point blame at them. I thought carbide was supposed to test everything before shipping?

If you are one of the people that bought the VFD and spindle kit for almost 800 bucks where the listing said they test and break in each and every one before shipment how on earth do they get to you broken in the first place? Because they aren’t testing that’s why. The fact that things are leaving not being tested at all is clear. Cost cutting mode engaged.

A full output sweep of 5 volts at not only power on but also USB connect isn’t “normal”, and if it is Carbide didn’t design a device that controls a spindle. Floating pins isn’t normal. Forgetting pull up or pull down resistors isn’t normal. Cold solder joints in production isn’t normal. None of this crap is normal.

All of our VFDs have shipped with a circuit similar to the one @gibs posted. You need something like that to do it correctly (I’ll assume his is correct; I didn’t look closely).

The Shapeoko 5 Pro electronics were designed to eliminate EMI/ESD as much as possible, which meant adding optoisolators everywhere, including the spindle output. That might mean that you need some signal conditioning to get your VFD working with it. Our VFDs already include that.

There are people who’ve opened up the electronics and connected directly to the CPU pin to get the raw PWM signal. Obviously, we don’t recommend that, but it’s your choice.

Support will work with you to make sure your electronics are not missing the pull up resistor, which would be a problem for you. I can’t tell from your shipping date if you might be affected, but I think yours probably shipped before the batch with problems. If you’d like to just swap out the electronics that you have, let Luke in his email thread from support.

I’m going to lock this thread because we’re in a loop here (and it was already scheduled to close tomorrow anyway). Your point is clear, our point is clear.