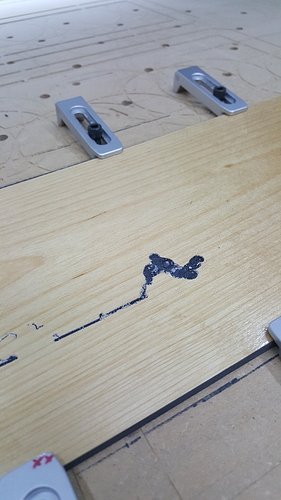

Here’s a reminder to never leave your machine unattended or at least not out of hearing range. This happened to me while I was running a finishing toolpath with a short 1/8" ballnose that did not need to go all the way to stock bottom. Short stickout, I eyeballed it and thought “this is going to be close, but it should be fine”. I was wrong. I did not notice but my toolpath happened to go a bit deeper in some areas, and the spindle collet nut came crashing on a part. Rubbing a piece of metal spinning at 20.000RPM on wood did not end well. That burnt area is 0.5mm deep. I only saw it (and smelled it) after the spindle retracted when I hit the feedhold button

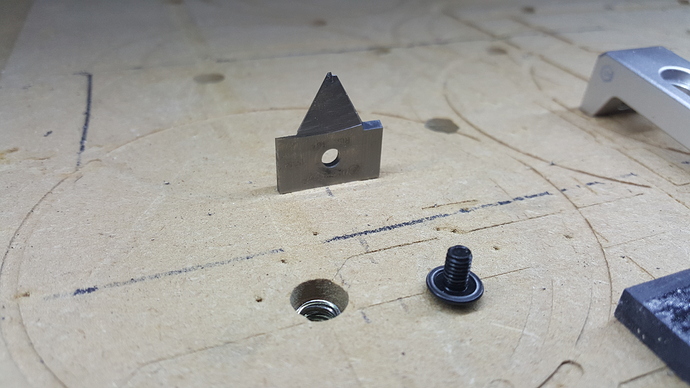

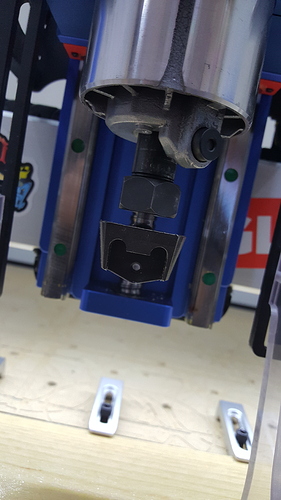

Yesterday I had a similar “should be fine” teachable moment… don’t assume that the set screws on carbide insert bits come tight from the factory… and (most importantly, I think) running insert bits without a protective barrier between you and the machine is just asking for a trip to the hospital with a piece of carbide buried in your gut. I know it would have given me a solid puncture wound if it hadn’t shot out towards the back left corner, gouging my waste board and the wall. This monkey is feeling rather stupid today…

Aaaand I just developed a mild case of inserts-phobia now

Glad it ended up with no injury, and I’ll see you later at the “I feel stupid today” bar.

What is making me feel so stupid, and compelled to share, is the fact that the first time I saw an insert bit I said to myself, “Oh hell no, what idiot would run one of those outside of a fully enclosed machining center…”

Edit: to be fair, I know plenty of people use them with no incidents of failure… I have a smaller 90 degree amana insert bit that has never shown signs of loosening, heck I don’t know if I am going to be able to change out the insert when the time comes it seems so tight.

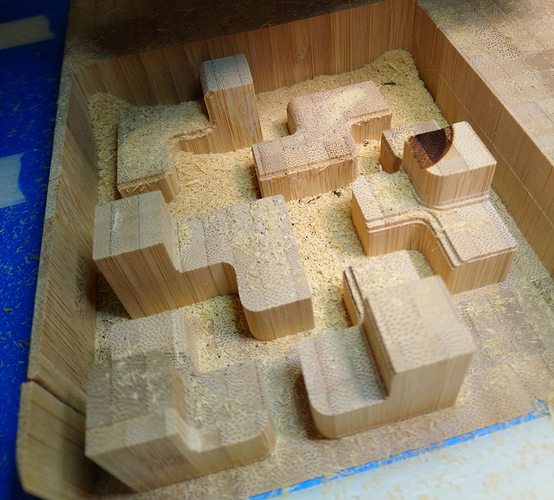

Are you making a puzzle?

Yeah, just for fun to play along in challenge #12

Remember the Sherpa Mantra - “Anyone can make a mistake, but Special people share them” !!!

Jon

Hey @Microwave_Monkey have you got a link to that insert Mill please?

Jon

Rough day for me too. I had a new 30deg engraving bit, one of the really solid, .025" ones, drop from the collet after I thought I had hand tightened it enough. I let go to reach for the collet wrench, saw it go, somehow managed to, in a split second, consider my options and decided I did not want the new tip to get damaged. Like a ninja I went to catch it and it embedded about 5mm into my finger. The tip was saved but my wife thought I had cut off a finger with the amount of blood that followed. Didn’t think to get pics for this thread…barely a mark today. Those things are sharp!

60 degree: https://www.toolstoday.com/v-14428-rc-1064.html (note: kinda odd after I sent them an email containing the exact pictures posted, it now shows a “pre-order” button instead of “add to cart” when I look at the product. More than likely purchased one of the last ones in stock…)

90 degree:https://www.toolstoday.com/v-10600-rc-45711.html (Currently really enjoying this bit, it cuts super clean even through masking)

You can’t beat a gory pic of a minor accident

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.