4/13/2016 I received my Shapeoko3 XXL today. I’ll keep this thread updated as I get further along.

I’ll preface this post by saying I’m a Nomad883 owner and other than some logistical issues I had a great experience there. I like that machine other than the very underpowered spindle. It lets me do things I couldn’t do before with 3D printing or a manual kneemill.

My first impresions of the Shapeoko3 XXL assembly process are mixed but I’m not that frustrated because startups like C3D have a rough life. They don’t have the resources or experience to control everything as well as more established companies. They do offer products that do a lot for not a lot of so its worth dealing with some growing pains. I don’t get perfect service from well established companies either so I’m not complaining.

Its a heavy box! It looked to be in good condition. I think the shipping info said 150 lbs or so. This thing is beefy compared to the previous versions.

I started unboxing at 3pm

There were no instructions, parts lists or even a reference to where to find assembly instructions. That’s disappointing but we like to figure things out so I didn’t really care. There’s not that much assembly left to do anyway.

The unboxing…

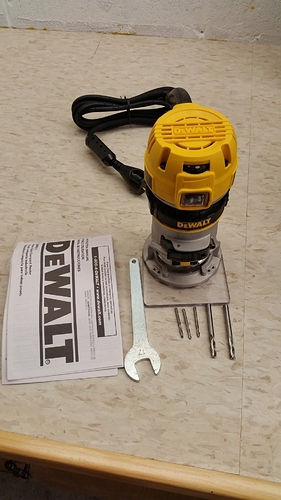

I was pleasantly surprised to see 5 carbide router bits included with the DeWalt router…

I laid out the base frame. Its pretty beefy sheet metal for this level of machine. The bulk of the weight is in these 5 pieces. Nice powder coating and the PEMSERTs are a great design feature.

The carriages are all pre assembled so I just installed them onto the rails. All three rails are the same extrusion and the same length except the X-axis rail has two threaded holes to mount the control card box. Two of my rails had the two holes so that probably means someone else got a kit with three rails with no holes.

The carriages were not adjusted properly. One was too tight and the other two were too loose. I tried one carriage on all three rails and it fit differently on each rail so the dimensional accuracy of the rails isn’t as tight as I would expect for CNC equipment. I don’t know how straight they are but I’ll check that later.

Of course, I put the first carriage on backwards. I pulled up a picture of a Shapeoko3 to figure that out  I called Carbide3D to see if there were any instructions available and they said to go to the Shapeoko webpage to find them. I just had my phone in the shop. I tried downloading a .PDF that said instructions but I don’t know where it disappeared to so I just used my superpowers of deduction to figure out where the few remaining parts had to go…

I called Carbide3D to see if there were any instructions available and they said to go to the Shapeoko webpage to find them. I just had my phone in the shop. I tried downloading a .PDF that said instructions but I don’t know where it disappeared to so I just used my superpowers of deduction to figure out where the few remaining parts had to go…

So far so good…

Now, I start scratching my head because the leads on the XY and Z steppers are too short to allow full movement and I didn’t get any cable extensions. I called Carbide3D and Apollo said “email Shapeoko” to let them know what you are missing". At that point I was wondering why I didn’t just buy the kit from Shapeoko. I asked if I could talk to someone at Shapeoko to discuss the problem. Apparently that’s not possible. When I persisted Apollo said he would email them to ask them to ship me cable extensions but he couldn’t provide any confirmation that they were going to do anything. He said I “might” get a confirmation email tomorrow.

At this point I realize there are more holes left than there are screws. I figure I can find whatever screws I need and even make brackets if they are missing but its kind of tough when there’s no assembly instructions. I don’t like that Carbide doesn’t have control of the process either.

However, I purposely didn’t plan on having anything depending on this machine. I know C3D employees are probably not loving life right now and probably won’t be for a little while to come with this kind of poor quality control. I’m not upset though. Its part of the price you pay for getting a machine from a startup and not paying the huge markups that more expensive machines have. I feel like its a fair trade so you just have to prepare yourself. I like these guys and will probably keep buying from them. This is a very good machine for the relatively low price tag.

So, right now I’m dead in the water with no assurance that Shapeoko will send me what I need anytime soon. I’m pretty sure there are several other pieces of hardware missing but I don’t know which ones because I don’t have a parts list and no one has offered to send me one.

I’ll keep you posted as this progresses…