Until today building this machine, while requiring a lot of work, was rather effortless. Was really excited when spindle cable arrived because was itching to spin this bad boy up and see how the initial cuts will look like. Already knew what settings on the vid have to be adjusted and how to properly wire it, so was supposed to be easy sailing.

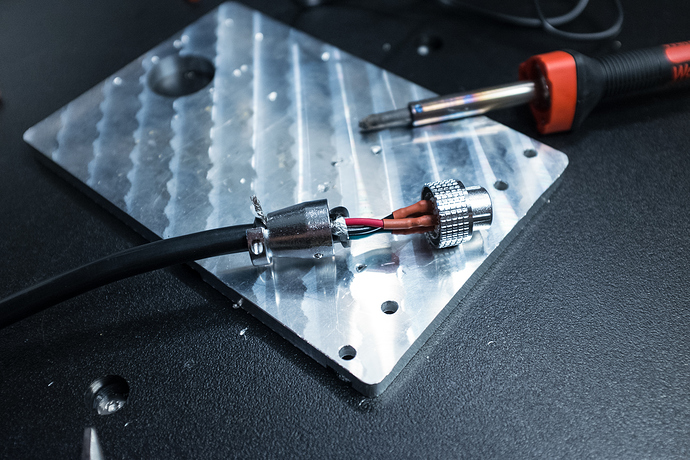

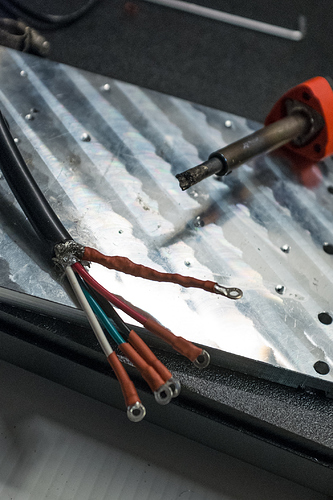

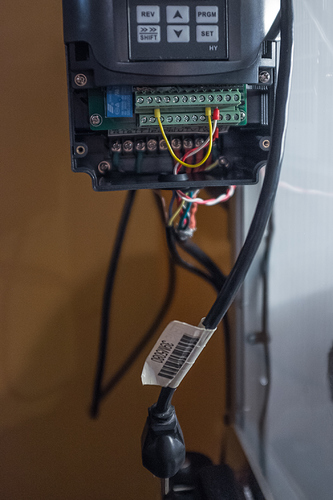

Cable shield was slid between the rubber jacket and plug’s metal housing on one end and fixed to the ground connection on the vfd’s end. Before I get bashed that this is not the best way to tie a shield to the vfd - i know, but since my vfd is not in a metal enclosure i didn’t see any way to wrap a grounding clamp around the metal braided sleeve, so just pigtailed it to the ground terminal.

Every ring and spade connector on this machine was soldered and properly isolated to make sure that the machine won’t be prone to emi issues. While it doesn’t seem like a lot of work with one cable, doing entire machine this way takes a lot of time.

Ferrite bead on the spindle cable was absolutely unnecessary. Added it to stiffen up the cable around the plug. Plus it looks kinda cool. lol.

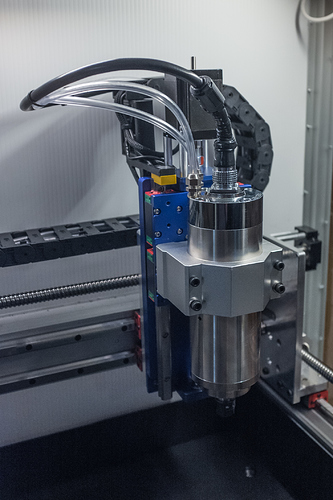

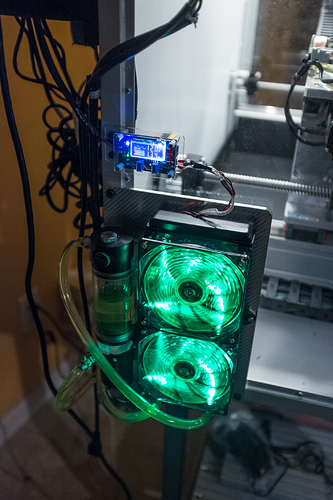

Spindle was all setup but before I could fired it up, had to finish plumbing. All the hoses were already in place, all that needed to be done was to connect a step-down converter to the water pump and fans and top it up with coolant.

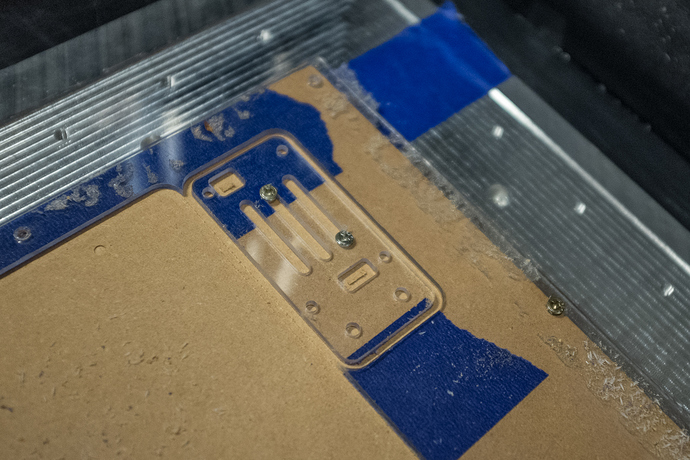

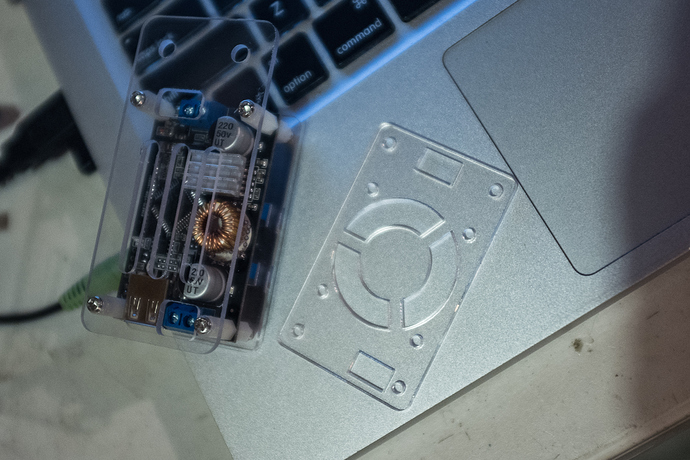

Didn’t know where to install the buck converter and specifically didn’t want to use double sided tape or any other sketchy method so milled a new back plate, from the remaining polycarbonate and bolted it to the enclosure.

Step down converter was connected to the 24v psu and now is powering all the plumbing equipment.

Couldn’t be happier with all the disco lights on this side of the enclosure, if not for the fact that the water pump is leaking  I knew there was a crack around the water fitting but was hoping that plastic welding it would fix it. Well it didn’t! Seller already sent a new unit, but when will it arrive from china, hard to tell. So this is the first disappointment of the day. But the water is circulating so let’s see how the spindle spins for the first time.

I knew there was a crack around the water fitting but was hoping that plastic welding it would fix it. Well it didn’t! Seller already sent a new unit, but when will it arrive from china, hard to tell. So this is the first disappointment of the day. But the water is circulating so let’s see how the spindle spins for the first time.

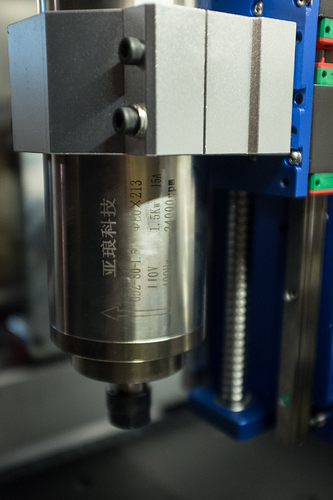

Here comes the disappointment #2!!! Decided to go with the 1.5kw spindle because already had a HY 1.5kw VFD. Didn’t realise that the spindle that arrived is rated for 15A.

Kind of ignored any spindle related topics until today, because I already knew how to wire it all up. Besides there was no info on the seller’s website regarding that. My 110v 2.2kw spindle is rated at 8amps so when I noticed that this is almost double i was shocked. I’ve seen 2.2kw 15a spindles but never 1.5kw at such high rating. Needles to say, spindle made two slow turns and the vfd threw out an error code. Yhhhhhh…

So now I’m wondering what should I do. Pick up higher rated vfd, or get a 2.2kw spindle? I’m actually leaning towards 2.2kw spindle with er20 collet but maybe someone has a better idea? Thanks in advance for all the input.