Can’t believe it took nearly a month to finish this build, there’re few more little things that need doing, but yesterday had finally a chance to test the machine, but about that later.

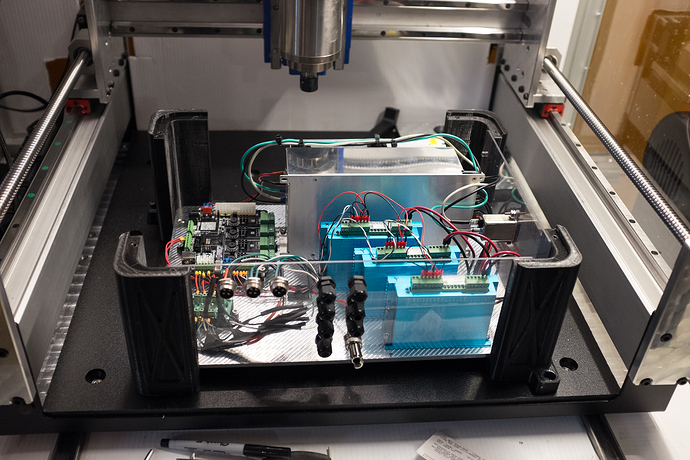

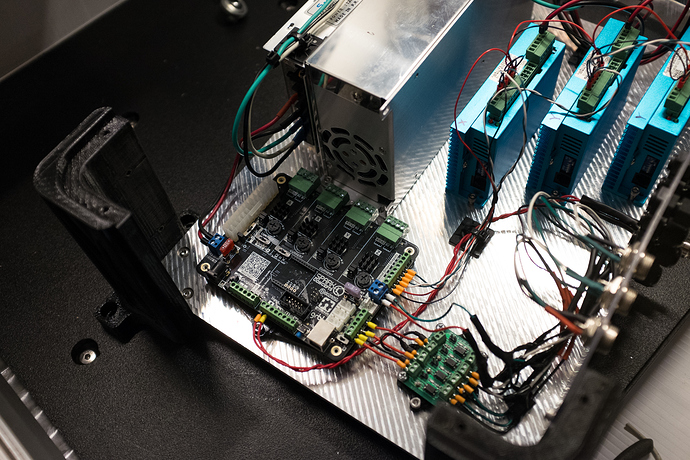

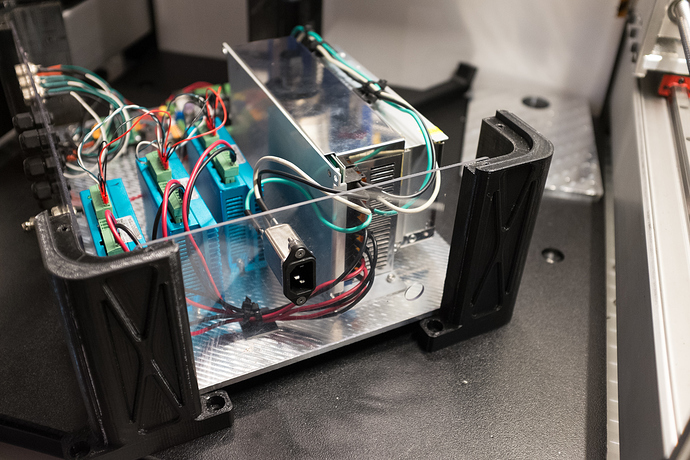

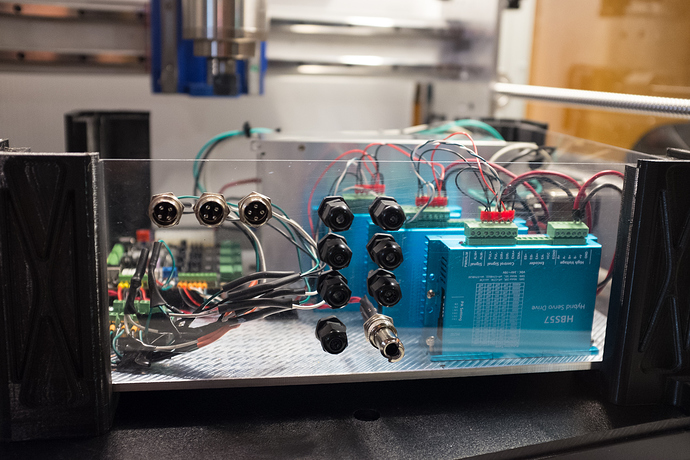

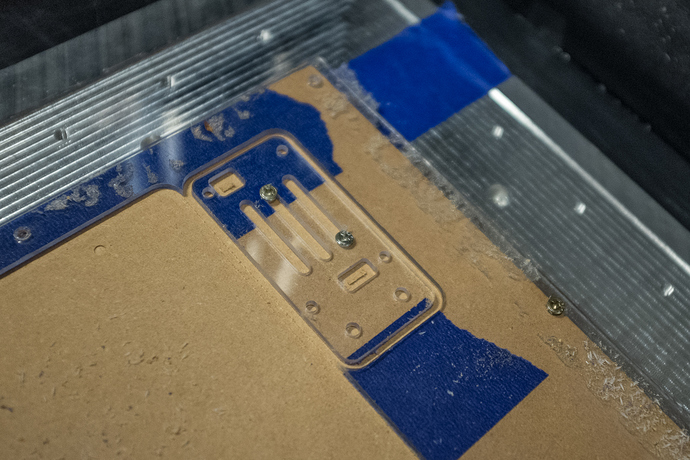

I’m nearly done with the electronics enclosure. Mounted all the components to the aluminum plate and wired everything up. One big complaint that I have is the INSANELY loud fan on the 60v power supply. I wasn’t expecting that tbh. My other cnc uses 48v psu which is pleasantly quiet but this thing is even worse than an obnoxious fan on the HY vfd. Once I’ll add all the plastic covers to the enclosure it should muffle the sound a bit but it’s still going to be annoying. Speaking of plastic covers - I used some leftover polycarbonate sheet that was mounted on the door of my previous wooden enclosure.

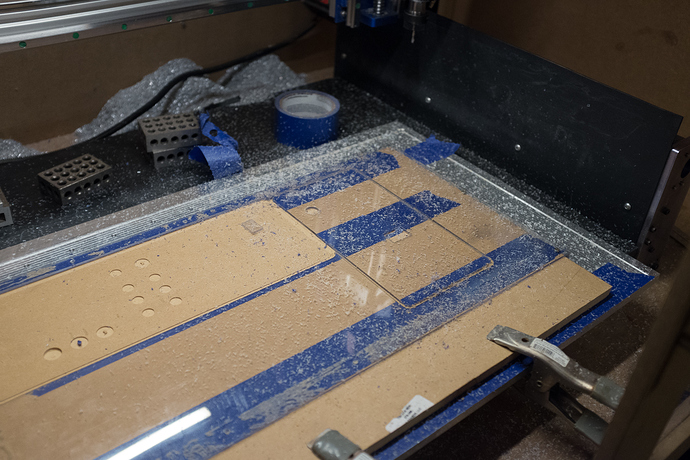

Since these were all contour cuts didn’t even bother surfacing the mdf wasteboard. That thing cuts like butter. Don’t know what settings I were running exactly at, but the faster the better. Probably around 24k rpm 2400mm/min 1/8" 2-flute end mill, and 24k rpm 3600mm/min 1/4" single flute end mill.

There’s still one thing that I have to figure out regarding the electronics. Where and how to add an e-stop. Since the enclosure is in the back of the machine and access to it won’t be easy, without moving the entire thing away from the wall, I’m actully thinking of mounting the e-stop (red button) at the front of the machines enclosure. It would be wired between the PSU and a EMI filter/power cord socket. So it would work as an on/off switch for the entire machine but also as an emergency kill switch - should anything go wrong. I mean … I didn’t really have to say that as it’s rather self explanatory how it works.

On the other hand it would probably be better to splice a power strip cable and add an estop there. It would kill everything off at once - router, spindle, lights. This would be most ideal solution for me - any reasons why this isn’t a good idea?

So, I’ve mentioned that I already tested the machine. The smartest decision I could’ve made was going closed loop. Motors and drivers were about $60-$100 more - depending where you order yours from - but it’s a huge improvement over regular steppers. They’re quieter, run cooler and prevent machine’s gantry misalignment. I started testing speeds and just for fun tried running at 20k mm/min with 1200mm/min accelerations and once the motors detected misalignment, they immediately paused the machine. Well, that happened instantaneously. Super awesome thing to have, especially after seeing my other cnc bend and warp like it was made out of cardboard.  After 30mins play I settled at somewhere around 12k mm/min rapids and 800mm/min accelerations. Plenty fast for me. I’ll try to slightly adjust alignment of ball screws on the y axis and see if I can get it to move any faster, but do I really need to? Can I really cut this fast?

After 30mins play I settled at somewhere around 12k mm/min rapids and 800mm/min accelerations. Plenty fast for me. I’ll try to slightly adjust alignment of ball screws on the y axis and see if I can get it to move any faster, but do I really need to? Can I really cut this fast?

You have to stop or they’ll need to redefine the coolness scale !

Also you need to find a suitable name for that machine, at this point “Shapeoko” is now only a very, very remote sibling

Thank you. While I like what I built and I’m sure it’ll do great job cutting aluminum (that’s its main purpose) it’s nowhere near as cool as this build thread. https://www.cnczone.com/forums/diy-cnc-router-table-machines/328752-cnc.html

Haha, it sure does deserve a new name since all that’s left from the original so3 is frame. However, it is also one of the most important parts of the machine and I’m glad I went this direction. Carbide 3d really did a great job.

Also you need to find a suitable name for that machine, at this point “Shapeoko” is now only a very, very remote sibling

Like maybe ShapeOko-Saurus Rex?

Shapeokozilla ! (and extra chars)

According to the rules:

https://wiki.shapeoko.com/index.php/The_Rules_of_ShapeOko

it’s still a Shapeoko, no matter how much it gets upgraded:

- No matter how much you upgrade your machine, it is still a Shapeoko (and all upgrades to machines must be recorded in one’s signature line and documented in the wiki).

My wife definitely agrees with rule #5:

“Rule #5 — You will be amazed (and embarrassed) at the places you will find little white flecks of HDPE”

Aluminum chips everywhere ![]() hehe

hehe

I must have missed this. Are those closed loop motors plug and play with the current steppers? Was that why you shifted to the higher voltage PSU?

They’re both nema23 and that’s where the similarities between stock motors and these end. Short answer would be no. Closed loop steppers require drivers with an encoder that detects stepper’s position and corrects it if needed, so theoretically they should never loose steps. Carbide 3d board has built in stepper drivers which means that - while you’re able to replace the motors for bigger ones, it’s often pointless because they’re limited to the voltage and current that driver can supply.

The reason why I went with higher voltage psu is because ball screws require considerably more power to drive them compared to belts. Also, if you look closely I have two PSUs - 24v and 60v. 24v powers bread board and Z axis motor ( because I don’t need 10000mm/min rapids on a z axis), and 60v psu powers x and y motors. 60v psu should handle additional motor, so if I decide that z axis needs to be faster I can buy new external stepper driver.

Hope that makes it a bit more clear.

You forgot one rule: The appropriate number of Shapeoko(N) to own is N+1

I came across that build some time ago, it is next level!

Congrats on getting to the testing phase, your machine looks badass, I can’t wait to see it in action! Your rapids look pretty good, I think on smaller machines 12k mm/min rapids is a decent figure. When you got to 4x8 machines 25k mm/min seems to be what people target.

Absolutely love the attention to details on that build but designing something so intricate takes time. A lot of time.

Thank you. The machine I’m building is specifically designed to cut aluminum so I can’t see myself going above 10k mm/min with 24k spindle anyways. I’m mostly using single and double flute end mills and stay within 3000-6000 mm/min but that might change. What I have to do is add some diagonal bracing to the metal table that the machine is mounted on. Been doing some air cuts yesterday, and the entire thing shakes pretty well near the machine’s top speed.

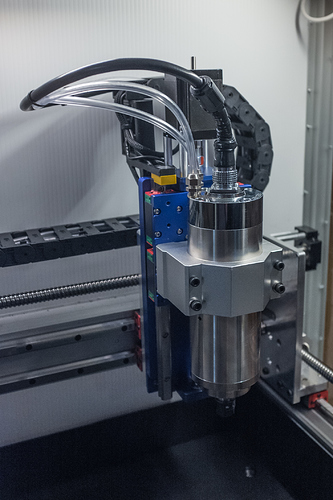

Until today building this machine, while requiring a lot of work, was rather effortless. Was really excited when spindle cable arrived because was itching to spin this bad boy up and see how the initial cuts will look like. Already knew what settings on the vid have to be adjusted and how to properly wire it, so was supposed to be easy sailing.

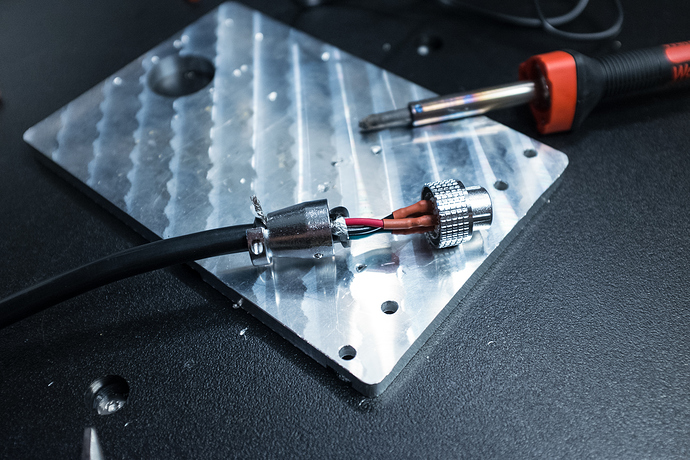

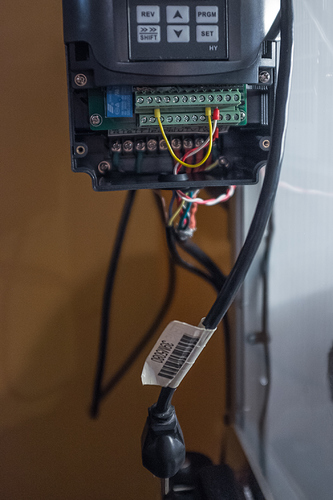

Cable shield was slid between the rubber jacket and plug’s metal housing on one end and fixed to the ground connection on the vfd’s end. Before I get bashed that this is not the best way to tie a shield to the vfd - i know, but since my vfd is not in a metal enclosure i didn’t see any way to wrap a grounding clamp around the metal braided sleeve, so just pigtailed it to the ground terminal.

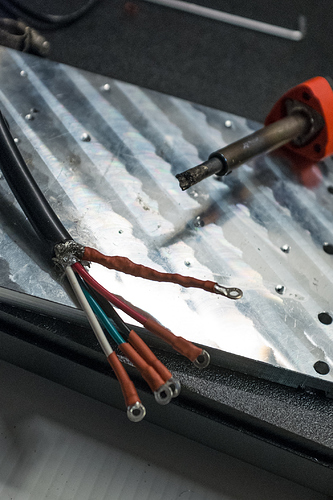

Every ring and spade connector on this machine was soldered and properly isolated to make sure that the machine won’t be prone to emi issues. While it doesn’t seem like a lot of work with one cable, doing entire machine this way takes a lot of time.

Ferrite bead on the spindle cable was absolutely unnecessary. Added it to stiffen up the cable around the plug. Plus it looks kinda cool. lol.

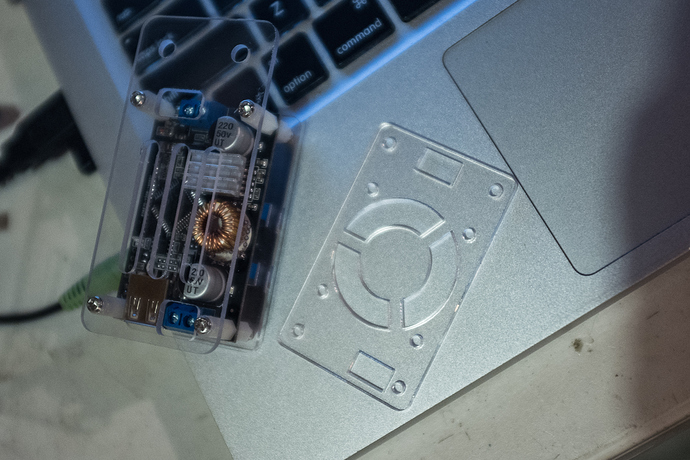

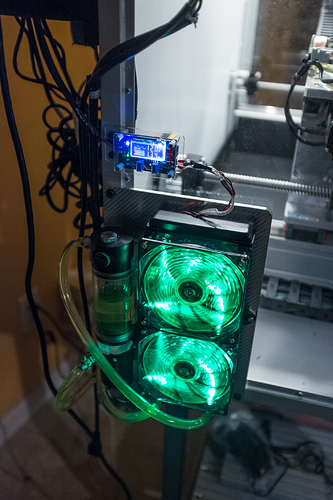

Spindle was all setup but before I could fired it up, had to finish plumbing. All the hoses were already in place, all that needed to be done was to connect a step-down converter to the water pump and fans and top it up with coolant.

Didn’t know where to install the buck converter and specifically didn’t want to use double sided tape or any other sketchy method so milled a new back plate, from the remaining polycarbonate and bolted it to the enclosure.

Step down converter was connected to the 24v psu and now is powering all the plumbing equipment.

Couldn’t be happier with all the disco lights on this side of the enclosure, if not for the fact that the water pump is leaking  I knew there was a crack around the water fitting but was hoping that plastic welding it would fix it. Well it didn’t! Seller already sent a new unit, but when will it arrive from china, hard to tell. So this is the first disappointment of the day. But the water is circulating so let’s see how the spindle spins for the first time.

I knew there was a crack around the water fitting but was hoping that plastic welding it would fix it. Well it didn’t! Seller already sent a new unit, but when will it arrive from china, hard to tell. So this is the first disappointment of the day. But the water is circulating so let’s see how the spindle spins for the first time.

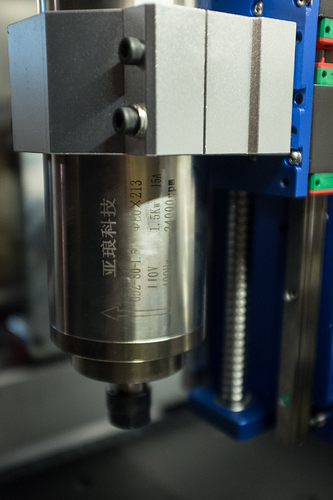

Here comes the disappointment #2!!! Decided to go with the 1.5kw spindle because already had a HY 1.5kw VFD. Didn’t realise that the spindle that arrived is rated for 15A.

Kind of ignored any spindle related topics until today, because I already knew how to wire it all up. Besides there was no info on the seller’s website regarding that. My 110v 2.2kw spindle is rated at 8amps so when I noticed that this is almost double i was shocked. I’ve seen 2.2kw 15a spindles but never 1.5kw at such high rating. Needles to say, spindle made two slow turns and the vfd threw out an error code. Yhhhhhh…

So now I’m wondering what should I do. Pick up higher rated vfd, or get a 2.2kw spindle? I’m actually leaning towards 2.2kw spindle with er20 collet but maybe someone has a better idea? Thanks in advance for all the input.

I’m confused at why you don’t like it is rated for 15 amps. 110 volts times 15 amps = 1650 watts, which is pretty close to the 1500 watt ratings. Meanwhile, your “2.2kW” spindle, if it’s only rated for 8 amps, is a far cry from the 2200 watts it should be rated for (110v8A=880 watts and 220c8A=1760 watts).

My E-Stop experience.

I have a 220v VFD/Spindle, everything else is 120, 24, 12. I also use E-Stop as on-off switch.

At first I had 3 switches stacked to one mushroom switch. Two problems, use the E-Stop while machine is running i.e., it’s intended purpose, everything shuts down as you would expect. BUT, the spindle continues to spin for quite awhile. 2nd problem, no easy way to just shut off the VFD/spindle for end mill changes. My preference.

So, two E-Stops on front of cabinet, one for VFD the other for everything else.

Also, if I E-stop the SO3 etc, the spindle stops quickly.

Hope this makes sense. I’m a woodworker not an electrician.

@The_real_janderson That’s exactly what I realized this morning. Had a brain fart yesterday when writing this and decided to simply switch the VFDs between both spindles. Makes me feel pretty stupid now especially after realizing that my 2.2kw spindle is merely an 800W with er20 collet.

Yes it all makes perfect sense. Appreciate input. What I’m probably going to do is install e-stop as a replacement on/off switch for the power strip and will move it to the front of the enclosure. This should allow me to use it in case of emergency to kill power to spindle and stepper motors. I’m often designing something or researching on the laptop sitting next to the machines and The only reason why I’m consider adding separate switch to the spindle is so I can turn the vfd off to safe myself from this pesky loud fan. Also killing the motors will stop machine’s movement immediately so I don’t really care how long will it take the spindle to coast to a complete halt, since it’s not ploughing through the material anymore.

Back to the spindle problems.

I’ve tried switching VFD’s and running this 110v 1.5kw 15A spindle of a 2.2kw 110v HuyanYang VFD but it’s a no go. VFD will only generate max of 11A (1.5kw VFD max 7A) and I’m getting an overload warning - A.oL or something similar. For a moment thought that maybe the spindle is broken but checked the resistance between each pair of phases (U-V, U-W, V-W) and they all read 0.5ohm. So the motor is good and it’s incredibly frustrating because I’d love to start cutting on this machine but I cant.

What’s the best possible solution that I have? I’ve narrowed it down to those options so please correct me if I’m saying something that makes no sense.

I could get a new motor that is rated at max 11 amps and runs on 110v. So in that case I’m ending up again with a motor thats around 1000W.

Or I could get a 220v 2.2KW spindle and VFD kit and for the time being try using it with the inverter. Double checked and all the power outlets are wired for 15A so should I be worried that the VFD will be tripping the breaker? If anyone has a better solution I’d appreciate any input.

could it be a setting in the VFD parameters that is set too low, and triggering the overload warning ?