I just used a router and a board clamped down as an edge guide.

Sorry for the late reply. I don’t remember getting a notification about these posts…

You can use any caulk but this is the acoustic caulk I used… Franklin International 2892 Sound Sealant, 28-Ounce, Green Amazon.com.

Just make a test rabbet joint a a scrap piece of acrylic to test the perfect depth. I think 1/16" extra for the caulk will probably get you very close.

Hi,

To begin, thank you for sharing!

Sorry for my bad english, but I’m french…

Your workspace has given me a lot of ideas …

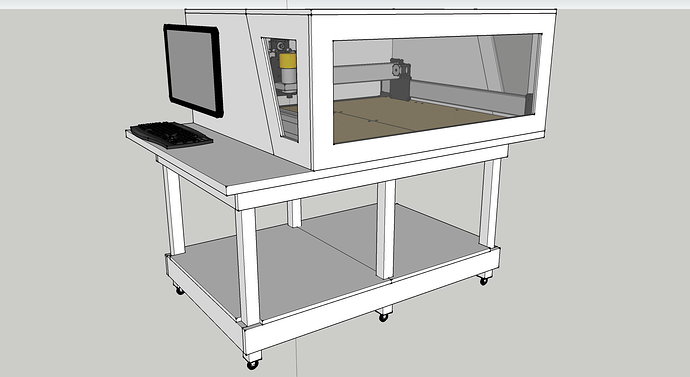

I started doing my workspace for my future Shapeoko 3 XXL.

To have room in my garage, I had to remove an old cabinet … And rather than throw it, I decided to use the wood to make my workspace …

Here is where I am:

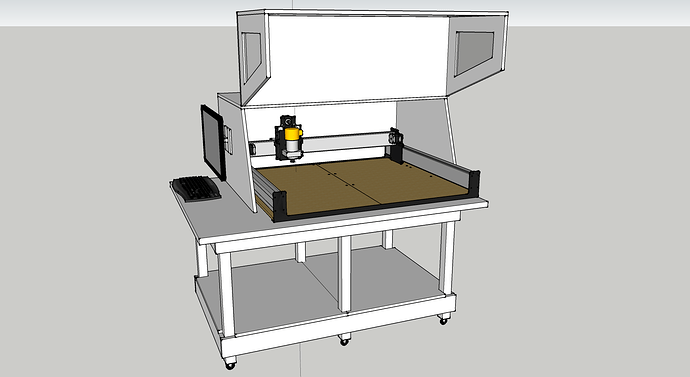

And the plan:

What’s the minimum inside depth for the enclosure to be closed, and being able to reach the entire cutting area with the router? Is 48" enough? Thanks.

45" is the minimum inside dimension. You will need more if your dust shoe hose sticks out past the front of the router mount.

You also want to make sure your cable management doent hit the back of the enclosure in a way that will interfere with it zeroing. I had to extend my table a few inches because of that.

Or shorten your y axis chain. Mine goes all the way to the rear stops and the chain doesn’t go past the rear plane of the machine.

In your plan you have the computer on the side but this could make it difficult to be in front of the computer while aligning the material or need to press the pause button. IMO, it is best that the computer screen and keyboard/mouse is in the same axis as the X so you can look at and operate both the computer and CNC at the same time. Maybe you could mount your monitor on a swing arm that you can turn and bring forward with the keyboard under.

Wow, I really like your plan.

you would do me a great favor if you can share your plan with us.

I hope one day i can reach your level.

That’s really nice setup,

would you mind sharing the plans with us.

I don’t know how to work with only my stupid head.

Many thanks

I haven’t made plans for it yet but drawing up a set of plans is on the (long) to-do list.

Here are a few layouts for an enclosure and torsion box w base. the 49" dimension may be a problem. I actually glued a 1" pc to some parts to achieve that . I am glad I left the extra room for the XXL. I still mounted the Drive electrical box connections out side.

I hope this helps at least it will get you off to a good start.

XXL Enclosure 11.14.PDF (26.8 KB)

XXL pcs VW_ai.pdf (55.4 KB)

XXL Enclosure LO 7.2.18.PDF (19.5 KB)

You can easily make it 49in without a joint if you use a sheet of Baltic birch plywood that comes in 60in X 60in.

How did you build your torsion box? It is not clear from the plans.

I used .75" light MDF for top and bottom and sides of box w 1/4" for interior members.

I glued and stapled the whole thing together. See the referenced photos also . I only did as much drawing as was needed for myself this is not Proper documentation I know. There are 5 pcs The base unit , the torsion box,the back main box of the enclosure w base plate which screws into the torsion box, and the hinged door. Be sure to allow a slot or whole in the base plate to allow for air to flow into the box so you have a good air plenum flow if you plan to use a vacuum in a closed fairly airtight enclosure like mine is.

<a class="attachment" href="/uploads/default/original/3X/3/5/3545513114b7bc86e915f6369f7491425f51b455.PDF">XXL Bench 10.31.PDF</a> (188.6 KB)

XXL Enclosure BASE & TORSION BOX.PDF (22.1 KB)

That looks great, Aaron.

THANKS- Tony - It works well in the very limited space I have

Sorry for dragging up this conversation again, but I cannot seem to figure out how to message people directly. However maybe more points of view can help clarify it for me. What are the internal dimensions of the enclosure with the foam? are there any clearance issues to worry about going around the full CNC? Trying to draw out my enclosure plans without having the CNC yet.

Click on the name of the person you want to message then you will see their info and a box to click to message them.