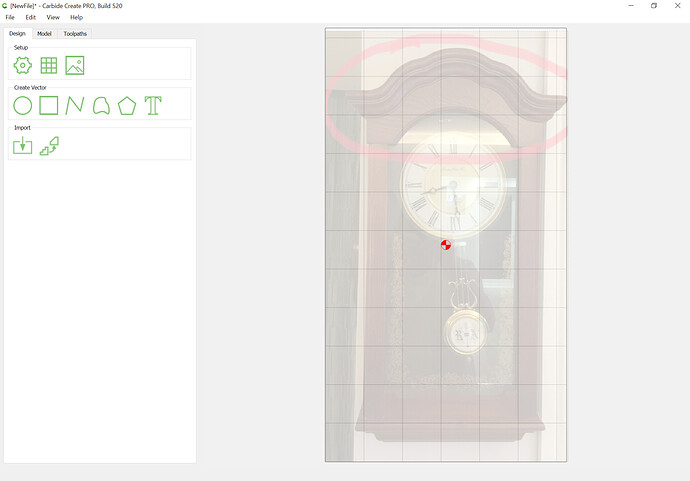

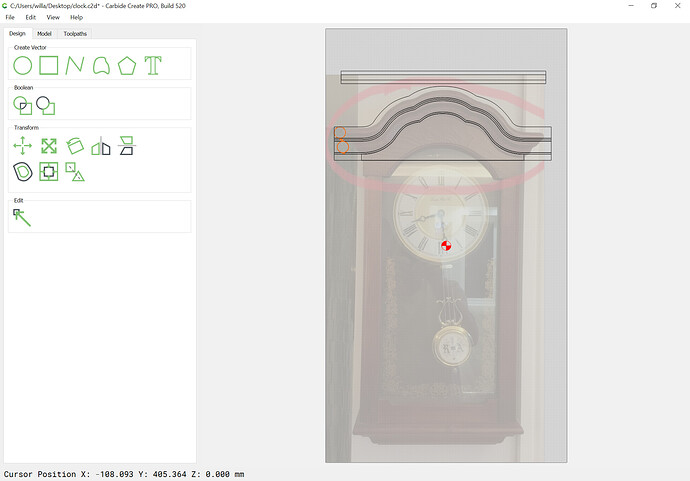

I am about to make a replica of this clock,the question I would like to ask would it be possible to make the top surround on the shapeoko??It is about 30 mm thick and approx 270 mm wide.Any thoughts would be very much appreciated.

Yes, but it won’t be possible to get a 3D preview of the rounded out top portion of the molding if using Carbide Create — it doesn’t support cove radius endmills:

One question is what sort of stock will you use and how will you work it? Options are:

- a single piece of wood which you remove a fair bit from

- smaller sections which are pieced together which will allow more efficient stock usage

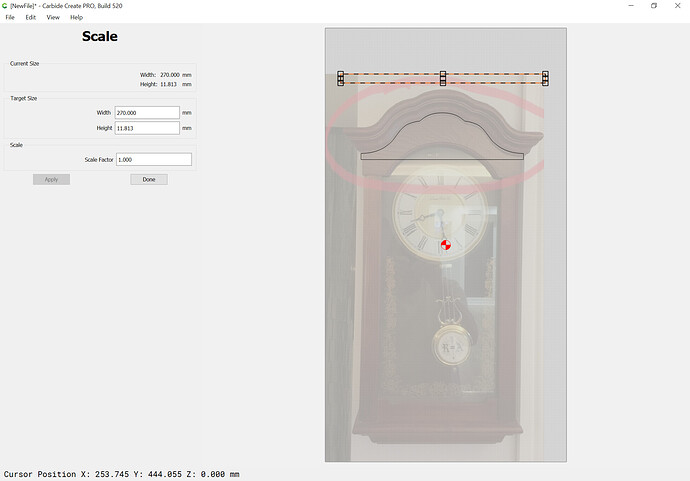

First thing is drawing up the outline of the design, and a profile of the molding along w/ dimensions — if you can provide a rough outline of the latter we can apply it to the former which would be easily drawn up from your photo:

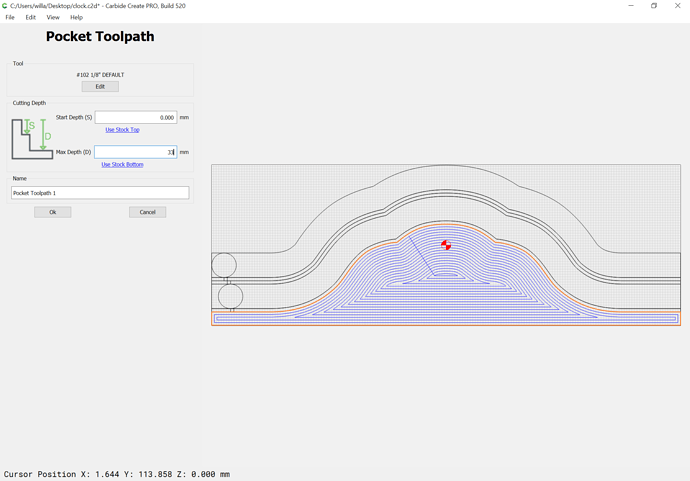

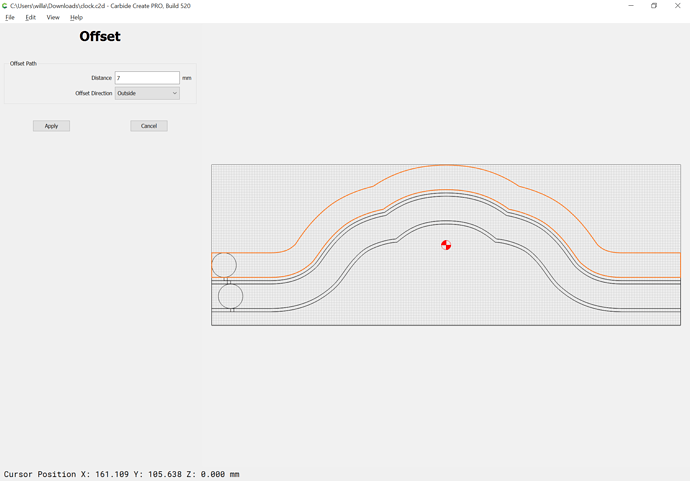

Once the basic outline is drawn up:

It’s simply a matter of offsetting it as necessary to to achieve the geometries needed to cut each level out.

clock.c2d (1.1 MB)

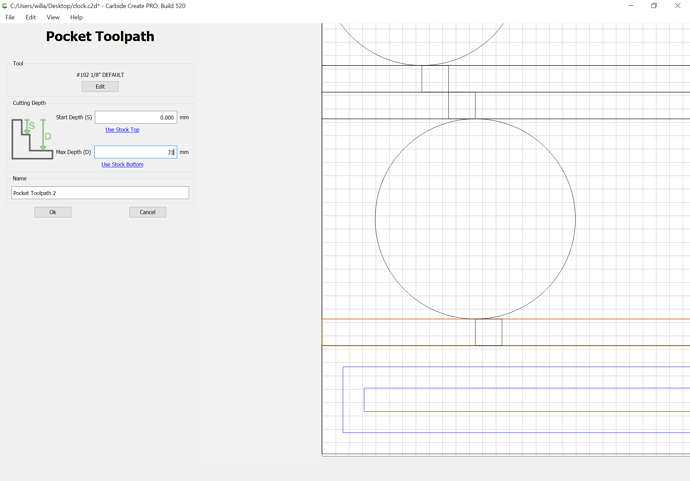

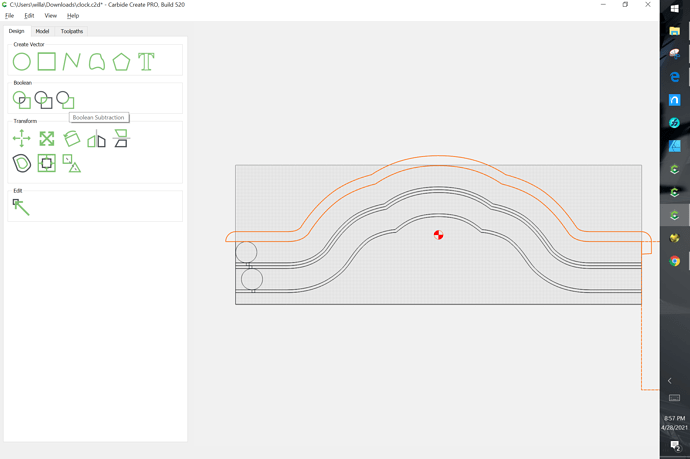

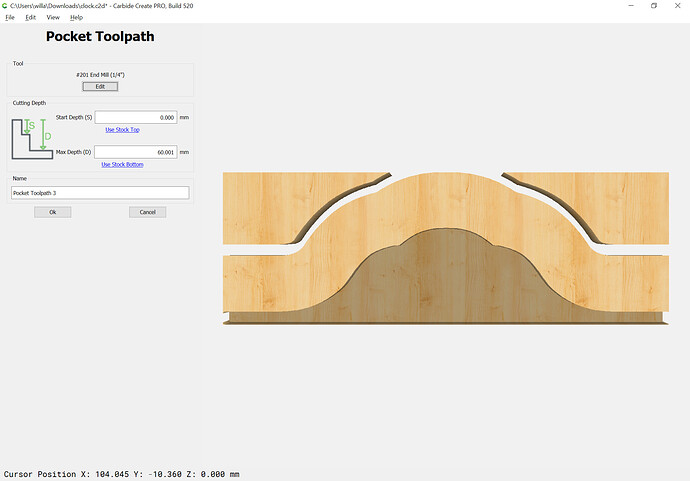

then assigning the toolpaths necessary to cut out each level (assuming using a single piece of wood for the stock (gluing it up might be expedient).

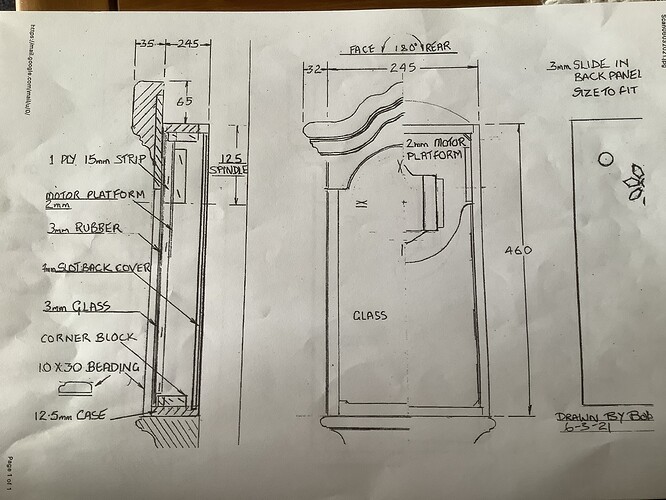

Hi Will,the material I am doing it out of is Macracarpa which is a little bit coloured and more tighter than a pine.We shifted house and had old macracarpa on the property and bought that with us.The story behind this clock is our friends came out from the UK and lived in NZ for 15 years and bought the clock with them,for me it looks great,they have since gone back to the UK and took the clock with them,hence wanting to make a replica.The husband has done all the drawings for me.

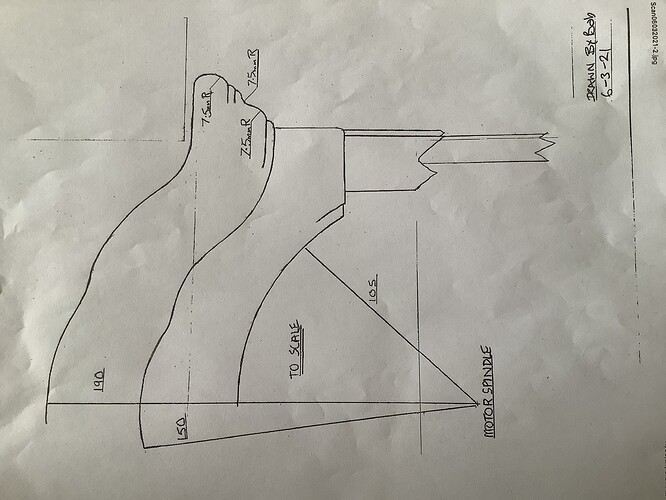

Okay, you’d need a 15mm ball-nosed endmill, and a 15mm cove radius endmill, but otherwise it looks like we could work out the balance of the profile — one thing not mentioned above is the return — probably easiest to use a slightly longer piece of wood and to cut it at an angle and miter the ends.

Hang on for drawing up the profile.

Will,where is the best source of those end mills??Can not see any available here in NZ

That’s a good question — McMaster-Carr? Perhaps Amana has them?

If you can’t source those sizes you might need to make do w/ the nearest size you can find, or model in 3D and cut thus.

Here’s my approximation of the profile:

Cutting it out would be a series of pocket and other toolpaths:

Here’s the file for you to experiment w/ — let us know what you work out about the ball-nose and cove radius endmills.

clock.c2d (1.2 MB)

I think the ball nosed endmill would need to be 30mm in diameter, and the cove radius would be 7.5mm

Hi Will,I will see what I can source tomorrow as today is a public holiday.The commercial cnc guys should be able to help

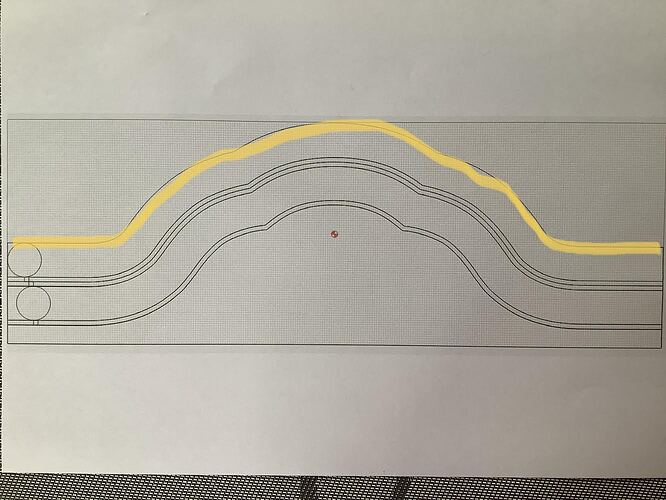

Hi Will,I need some help,the file you posted is brilliant but I only have one problem I can not work out,that is how do I set up to cut a contour cut on the top of the carving as per the photo,I am fine every where else but this has stumped me.

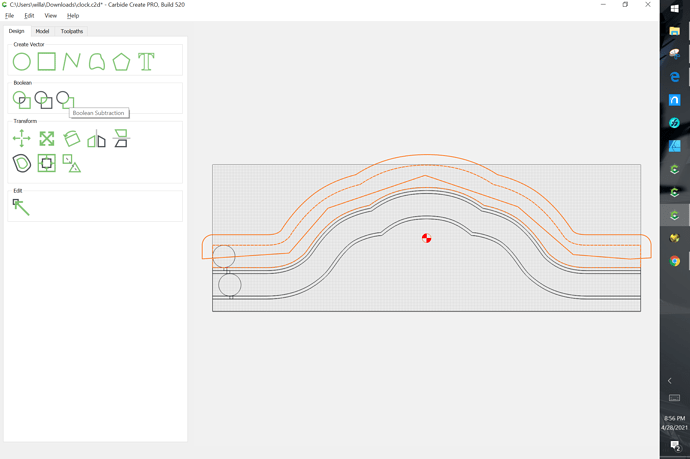

Okay, to create a cut which will only remove material along the top you need to offset by the diameter of the endmill plus 10%, so:

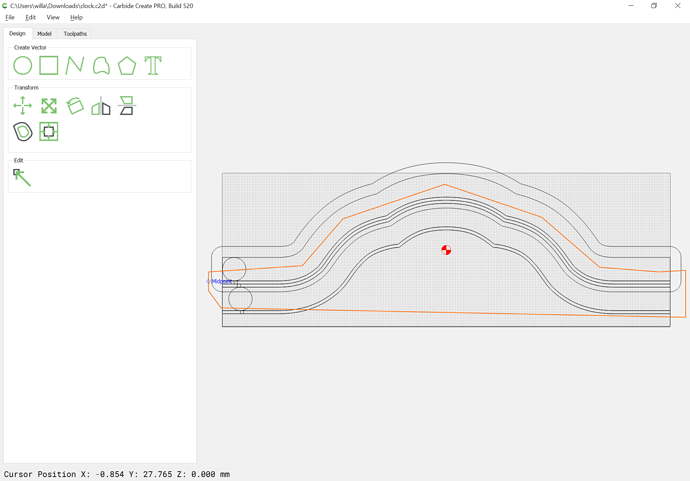

Then you need to reduce that to less than the original geometry:

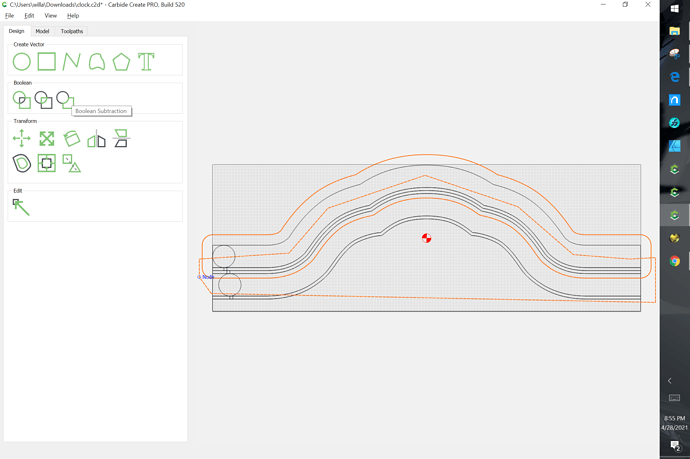

Boolean Subtraction:

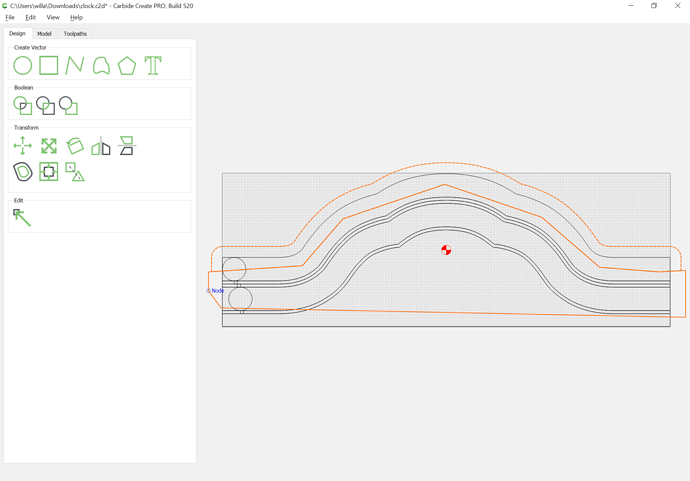

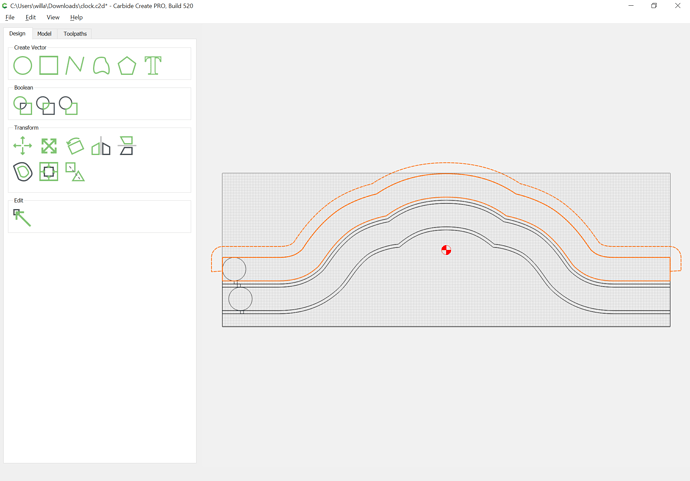

Delete the unneeded geometry, if need be duplicate the original, then select the remaining offset geometry, shift click on the original so that it is the key object (indicated by dashed hilight):

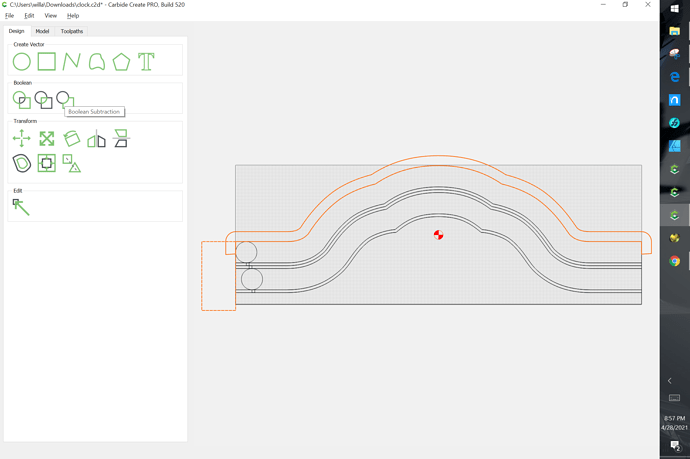

and clean up the corners:

It’s called Art to Part. This is a fairly easy part to produce if it’s correctly modeled in some 3D CADCAM Software (I recommend Fusion 360). From what I see it would require three standard cutters. 1/4" to rough, 1/8 Ball for most of the curves and a Tapered Cutter (0.015" End Radius) for the remaining few edges.

Same three cutters reproduced this 1790 Chippendale Ball and Claw Desk Leg.

I did it Will,thanks so much,I will treasure that procedure,I spent a good 2 days bending my brain to do it.I think for the vertical curves I am going to see if I can run around it with the trim router,that is cheating but I think it will work.

Hi Richard,thanks for the comments,I am trying to fully get my head around the CC then onto 3D,I need to set up a training item that is simple to learn on.I thought I had CC but this tripped me up

While ostensibly Boolean operations are straight-forward binary logic, achieving certain affects requires a bit of an outside-in approach and the creation of additional geometry which isn’t always straight-forward.

This topic was automatically closed after 30 days. New replies are no longer allowed.