Hello. Can someone help me with feed and speed rates. I continually get different answers. I make basic signs and wood flags. Any help would be appreciated.

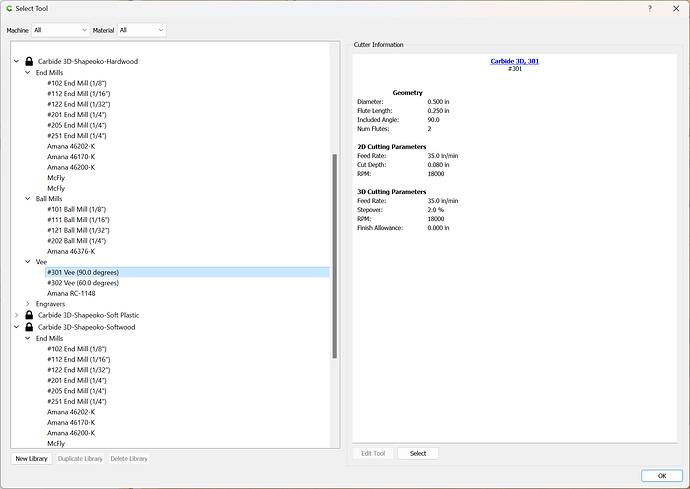

We have very conservative settings in Carbide Create:

for the tooling which we sell which should work as a starting point.

We have some videos on this at:

and hosted a pair of blog posts on the concepts:

https://carbide3d.com/blog/feed-and-speeds-part-1

https://carbide3d.com/blog/feed-and-speeds-part-2

and the community has put together a bit:

and at least one vendor rep here has a site entitled “Calibrating Feeds and Speeds when using Carbide Microtools”.

Thank you. Very helpful.

Buy a few different pieces of wood and create a few small pockets in each to cut out and try different speeds and feeds. I start with Carbide’s conservative settings and increase feed rate and RPM by 15%-30% (if you increase speed by 20% increase rpm by 20%). There is a lot of info on the internet about speeds and feeds, but nothing concrete like “use 22000 rpm at 80 ipm for walnut.” So, I just experiment and figure out what works for me.

It sucks and you’ll find 100+ threads on here even. It’s a challenging topic and you’ll see even different speeds from people using the same machine and bits with different results. There are just so many factors that add up to the end solution.

The only real way is to test and find out what works for you, with your wood, your project, your machine. You’ll find pockets vs profile cuts vs 3d all require different settings.

Use what you find and what’s in the tool databases as a starting point, and go from there.

This topic was automatically closed after 30 days. New replies are no longer allowed.