Is there an application for an android phone, that does speed and feed for wood?

List at:

(which is now off-line)

Notable things from that:

The free version is somewhat limited materials-wise but I still find it handy:

millright cnc has an app

If you have a Spreadsheet app on your phone, you can download the excellent free F&S calculator spreadsheet that was developed by @gmack and @Julien that you can find in the Shapeoko ebook V2 thread. I have it on my IPhone.

Like the Windows version, those spreadsheets should work on the free Android OpenOffice app.

Like most/all others, that calculator is likely intended for pro metal milling machines. Shapeokos and likely most/all CNC routers are limited by machine rigidity (i.e. cutting force) rather than spindle power as assumed by these calculators. As it’s developer Eldar Gerfanov says about his other product (HSMAdvisor):

"My software out of the box assumes you have the best conditions possible. That you use coolant and sufficient chip removal. It is up to users then to adjust cutting parameters based on their results.

It assumes machine is rigid and cutting forces do not cause positive loop or resonance issues sufficient to break anything.

Although I have lots of users with sub - 0.75kW spindles and small cutters, I can not promise you it will work in your particular set up. This is why you have 30 day trial to figure that out. If anything just to compare how your own experience matches the suggested results.

If it wasn’t for limited resolution, HSMAdvisor would be superior to GWizard because, unlike GWizard, it shows cutting force and adjusts its calculations for the selected specific metal “alloy” K-factor in each metal “family”. Unfortunately that’s not the case for wood. It uses a 10 cu-in/minute/HP for all woods (which is about right for Baltic birch and likely quite conservative for all but the hardest of woods.)

You are correct.

I’ll often use something close to the suggested feed speed, while using 1/2 to 3/4 D for my DOC.

I’ll provide a real-life example of a recent project…

Wood (hard maple). 4.75mm thickness. 1.5mm bit, two flutes, actually one of the bits I got for machining the printed circuit boards for another project.

Bit “stickout” is approx. 18mm, and flutes approx. 8mm. Shank 3.175mm.

The app suggested (for slotting) 27000-RPM, .3317mm DOC, and 30.14 in/min.

I ended-up using the 27k-RPM, but a 1mm DOC and 35 in/min. The 1mm DOC was arrived at by the scientific method of adjusting it until the # of passes seemed reasonable given my previous experience with these bits in the copper-clad phenolic.

I’d probably used closer to .75mm as a starting DOC but had a package of ten of the bits and figured breaking one wouldn’t be the end of the world.

This was for the tonearm project. I purchased a turntable on eBay (a 30-YO Technics SL-6) and it came with a tonearm that had a broken part. I ordered a replacement tonearm and the same part was broken (likely a stress fracture, later models redesigned this part).

So I harvested the platter and motor, figured out the wiring of the motor’s controller board (these are direct-drive tables where a ring of magnets on the bottom of the platter sort of turns the entire platter into the rotor), and made my own tonearm based on proportions from an SME Series V.

Here, this:

That is all very OT, but it goes back to my original method of using suggested feed speeds and picking a DOC of approx. 1/2 D of the bit.

I downloaded the F S spreadsheet. It has a link to a doc file. But the doc file does not exist.

Is there someplace that It can be downloaded?

It’s in the zip folder posted here. But you’ll probably find @Julien’s instructions in his latest e-book more useful.

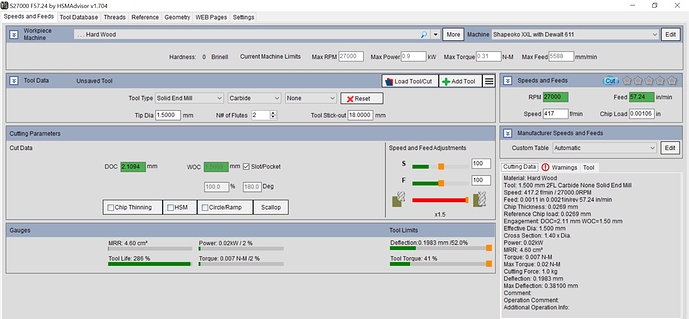

The latest version of HSMAdvisor recommends 27,000 RPM (because that’s as fast as the Dewalt can go), 2.1 mm DOC, and 57 IPM for a 4.6 cu-cm/min MRR at 1kg force and 20 W spindle power. Seems reasonable to me - but it’s a lot different than your reported app results. Do you have the latest version? If so, someone should tell Eldar! In my experience Eldar is much more receptive and responsive to feedback than BW. ![]()

Here’s HSMAdvisor’s recommendation (not bad IMO!):

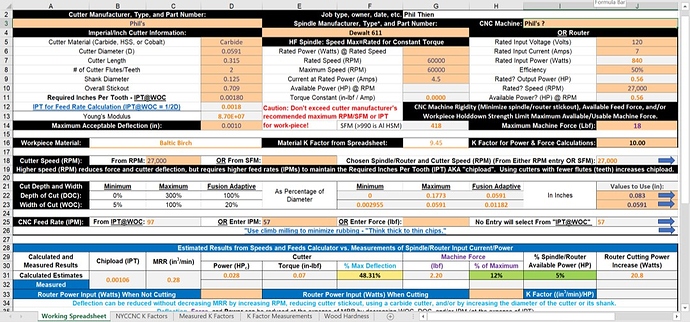

Here’s what the workbook comes up with those conditions:

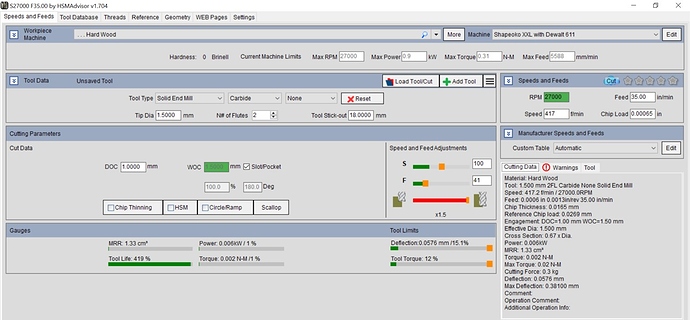

Here’s what HSMAdvisor says you reportedly ended up doing;

I’m not sure if I have the latest version, I’ll look into it.

Hmm…

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.