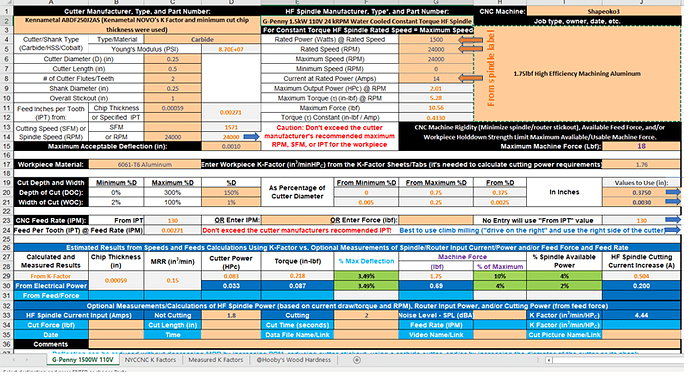

I made this one for the 1.5kW 110V G-Penny spindle recently SFPF Workbook for G-Penny 1500W 110V 24000 RPM HF Spindle.zip (169.4 KB).

Yup, as shown here:

There’s really not much to it - orange fields are for user entries.

In addition to the spindle info, cutter info needs to be entered. After entering the basics into cells C4-C10, desired spindle speed can be entered directly into cell C14, or it can be calculated from the cutting speed (SFM) entered into cell C13 and the cutter diameter in cell C6.

There are two options available for IPT and IPM feed rate calculations based on “chiploads”. (They are provided in cells D11 and C23 respectively.) You can enter either the desired cut chip thickness into C11 (which accounts for “chip thinning”) or the specified IPT from the manufacturer’s speeds and feeds recommendations (which doesn’t account for “Chip thinning”) into cell C12.

You can set the machine feed rate (IPM) to whatever you want in cell E23, have one calculated from a machine force limit entered into cell G23, or let it default to the calculated C23 value.

Desired DOC and WOC are entered into cells J20 and J21 respectively.

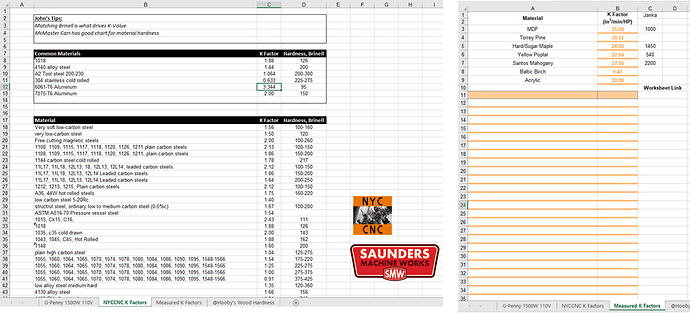

Workpiece material K-Factors approximate how much cutting power is required for the cutting parameters you’ve entered. As shown, some are available on other sheets (tabs) in the workbook.

IMO there’s no magic, high level math, or AI (yet?) to effectively advise you. The spindle and cutter essentially do all of the work, the machine positions the spindle to enable that, and it’s up to the user to determine what works for him/her. The workbook (and other calculators) just provides estimates of cutting power and machine force requirements based on estimated material and cutter characteristics.