Can’t remember exactly how the idea got into my head but for a while I’ve been putting off attaching an accelerometer to my spindle to measure “stuff”.

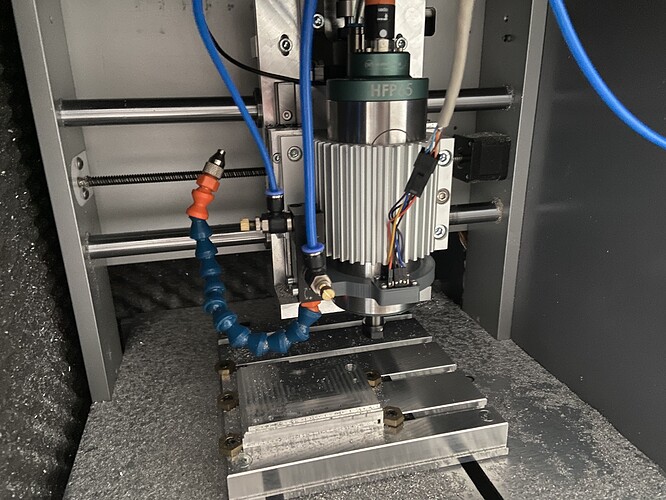

I finally got around to it:

It’s a 3D printed mount that clamps around the spindle body and has two slots for M4 nuts (for the MQL nozzle) and a little space in the front to hold an Adafruit ICM20649 breakout board. Attached to it via dupont connectors is a Molex Micro-Fit 3.0 connector, which connects to a 1m-long Cat 6 ethernet cable which has the same pile of connectors on the other size, except the dupont connectors go to a Teensy 4.1 running an Arduino sketch.

The Teensy 4.1 currently just spams SPI asking for data and spits it back over UART as CSV when it receives it. I then capture the UART output with my laptop.

That’s the setup and I haven’t done any cutting yet but I have done a few experiments. I wanted to test the following hypotheses:

- Does the collet make a difference (e.g. due to concentricity)?

- Does tool length make a difference (e.g. due to amplifying errors in concentricity)?

- Does the tool diameter make a difference (e.g. due to mass)?

- Does the tool make a difference?

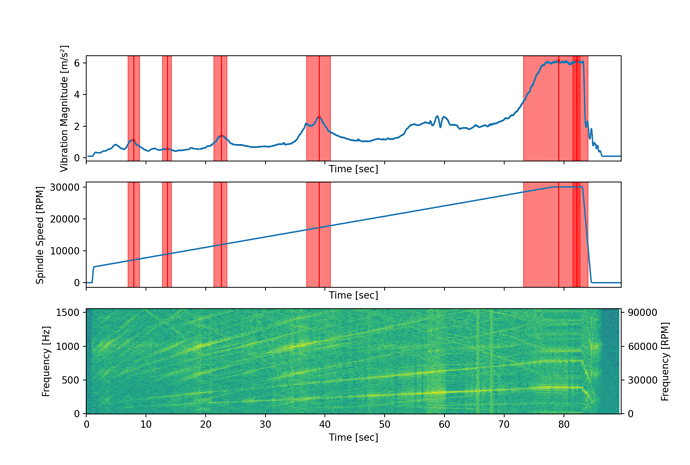

To test each of these hypotheses, I kept all else constant and changed the variable in question. In all cases, I ran a ramp from 5k RPM to 30k RPM, held the spindle at 30k RPM for 5s, stopped, waited until I didn’t hear anything else and then stopped capturing.

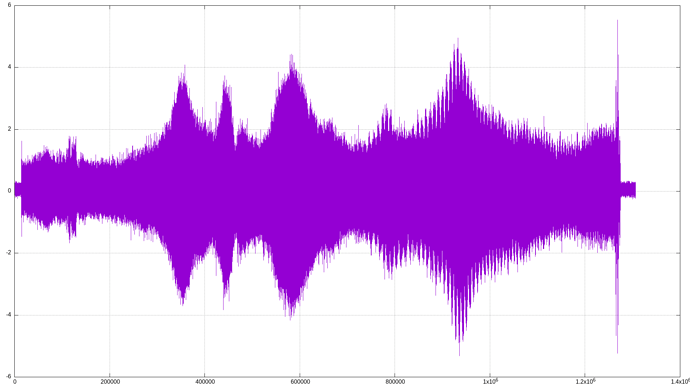

Once I recorded the data, I was mainly interested in how strong the vibrations were over time, so I just plotted them into a kind of waveform.

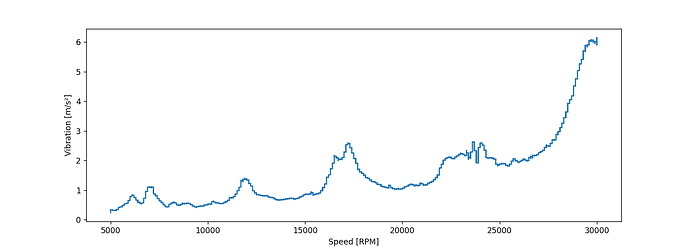

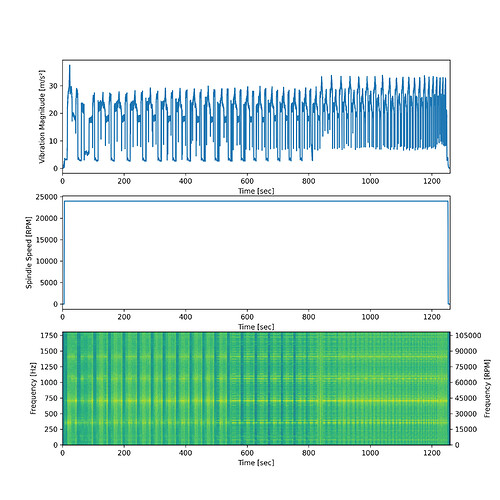

Here’s the waveform data with an empty collet:

Everything else should be looked at relative to this.

The waveforms I’m using show acceleration in m/s² on the Y-axis and sample number on the X-axis. There should be ~4120 samples per second. The spindle ramps up from 5k to 30k so the far left of the chart is 5k RPM and the far right is 30k RPM.

Does the collet make a difference?

I ran the following tests:

| Shank diameter | Collet | Endmill | Waveform |

|---|---|---|---|

| 3mm | GERC11-HP | DIXI Polytool | sampledata_speedramp_GERC11-HP_3,0_dixi |

| 3mm | 3.5mm GERC11-B | DIXI Polytool | sampledata_speedramp_GERC11-B_3,5_dixi |

| 1/8" | Probably Carbide3D | CNCFraises FC1DA3012 | sampledata_speedramp_NomadNut_0,125in_cncfraisesFC1DA3012 |

| 1/8" | CNCFraises | CNCFraises FC1DA3012 | sampledata_speedramp_CncFraises_0,125in_cncfraisesFC1DA3012 |

| 1/8" | 3.5mm GERC11-B | CNCFraises FC1DA3012 | sampledata_speedramp_GERC11-B_3,5_cncfraisesFC1DA3012 |

| 1/8" | 3.5mm REGOFIX UP | CNCFraises FC1DA3012 | sampledata_speedramp_REGOFIX-ER11UP_3,5_cncfraisesFC1DA3012 |

| 6mm | Sorotec | Sumitomo ASM2060DL | sampledata_speedramp_Sorotec_6,0_ASM2060DL |

| 6mm | GERC11-B | Sumitomo ASM2060DL | sampledata_speedramp_GERC11-B_6,0_ASM2060DL |

| 6mm | GERC11-HP | Sumitomo ASM2060DL | sampledata_speedramp_GERC11-HP_6,0_ASM2060DL |

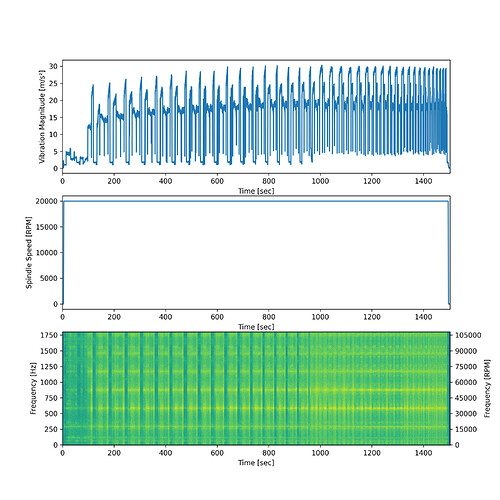

The spindle is held at 30k RPM for 5s at the very end which is why you see one largely flat blob there.

Conclusion: Yes, the collet absolutely makes a difference. If you compare the files for the 1/8" endmill, you can see:

- The “Probably Carbide3D” collet has a maximum amplitude of only ~10m/s², while the others are mostly around 15m/s². This is relative to a peak of ~4m/s² with an empty collet.

- They all show peaks in similar areas but the REGOFIX and Cncfraises collets both have a peak around 400000 on the X-axis, while the other two collets do not.

How big these differences are in practice, I have no clue.

Does the tool length make a difference?

| Shank diameter | Collet | Endmill | Waveform |

|---|---|---|---|

| 1/8" | 3.5mm GERC11-B | CNCFraises FC1DA3008 (8mm) | sampledata_speedramp_GERC11-B_3,5_cncfraisesFC1DA3008 |

| 1/8" | 3.5mm GERC11-B | CNCFraises FC1DA3012 (12mm) | sampledata_speedramp_GERC11-B_3,5_cncfraisesFC1DA3012 |

Conclusion: Needs more investigation. There is a difference, the 8mm tool peaks at ~11m/s² while the 12mm tool peaks at ~13m/s² but it’s not huge. Might need to try a wider variety of tools.

Does the tool diameter make a difference (e.g. due to mass)?

| Shank diameter | Collet | Endmill | Waveform |

|---|---|---|---|

| 3mm | GERC11-HP | DIXI Polytool | sampledata_speedramp_GERC11-HP_3,0_dixi |

| 6mm | GERC11-HP | Sumitomo ASM2060DL | sampledata_speedramp_GERC11-HP_6,0_ASM2060DL |

Conclusion: Yes. Bigger tool → more vibration.

Does the tool make a difference?

| Shank diameter | Collet | Endmill | Waveform |

|---|---|---|---|

| 3mm | GERC-11B | DIXI Polytool | sampledata_speedramp_GERC11-B_3,5_dixi |

| 3mm | GERC-11B | CNCFraises EVOMAX | sampledata_speedramp_evomax_GERC-11B_3,5 |

Conclusion: Yes. The peak around 400000 is different for both tools.

Sample 400000 by the way corresponds to somewhere in the region of 12k RPM.

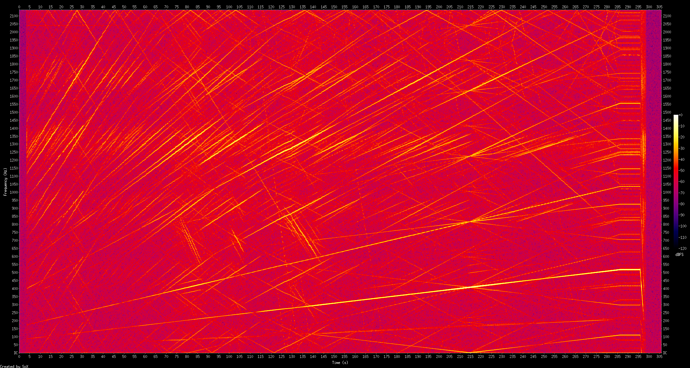

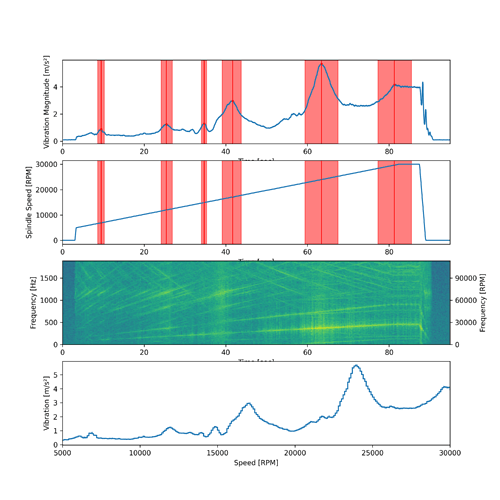

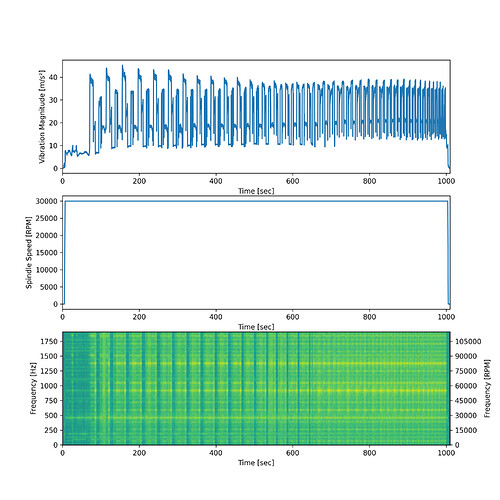

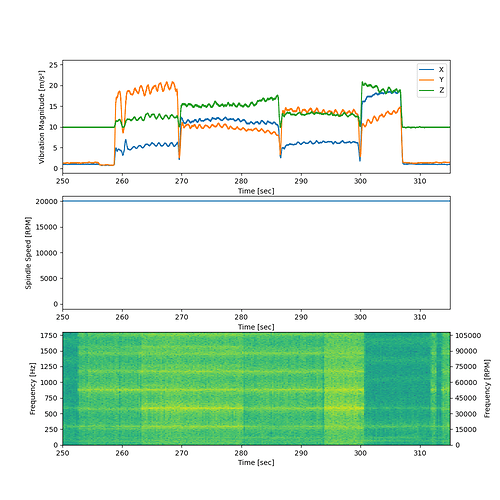

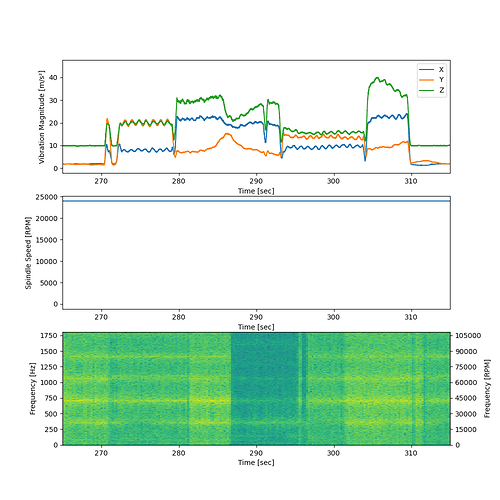

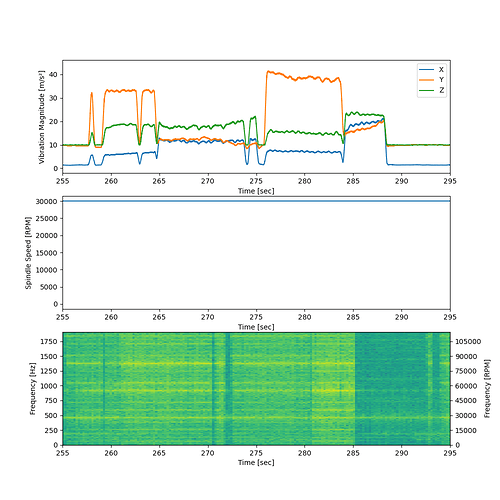

And because I have it laying around, here’s what a spectrogram looks like if I convert one of the CSV files to audio:

I have no clue what most of the lines I’m looking at are but it looks pretty. You can clearly see the spindle RPM ramping up.

My next projects are:

- Actually cutting

- If I run tools with similar specs and the same feeds and speeds, do I see a difference in the produced vibration, e.g. because of geometry or sharpness?

- If I avoid the peaks I see when running the tool in the spindle without any load, do I see any positive results when cutting?

- Looking at more tools

- Analyzing the data using all three axes of the accelerometer and not just the X-axis