Ugh, so I spent an hour this morning testing 10 endmills but when I came to analyze the data, turns out the accelerometer had written all zeroes for some reason

Still, I did take photos with the microscope and that’s still interesting (open these in a new tab to see full-size).

| Endmill | Before | After | Pocket bottom | Pocket corner |

|---|---|---|---|---|

| CNCFraises FC1DA3008 | ||||

| CNCFraises FC1D3008EVO | ||||

| Carbide 3D ZrN Single-Flute | (Missing) | |||

| DIXI 7561 | ||||

| Sorotec Alu | ||||

| Sorotec ProAlu | ||||

| Sorotec Alu-B | ||||

| CNCPlus 102-30 | ||||

| Janpo 1MEM | (Missing) |

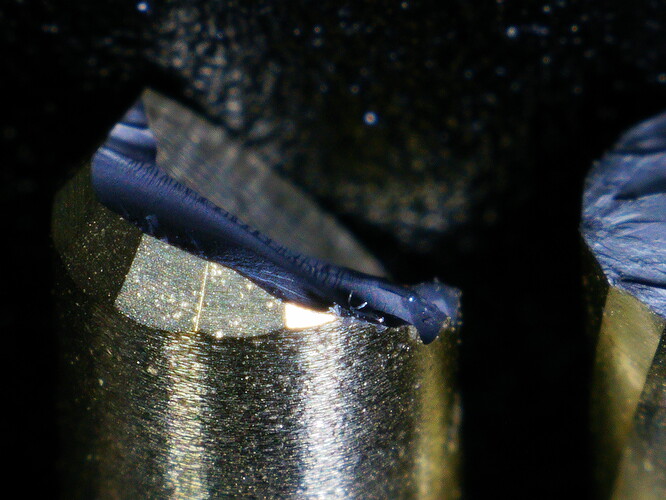

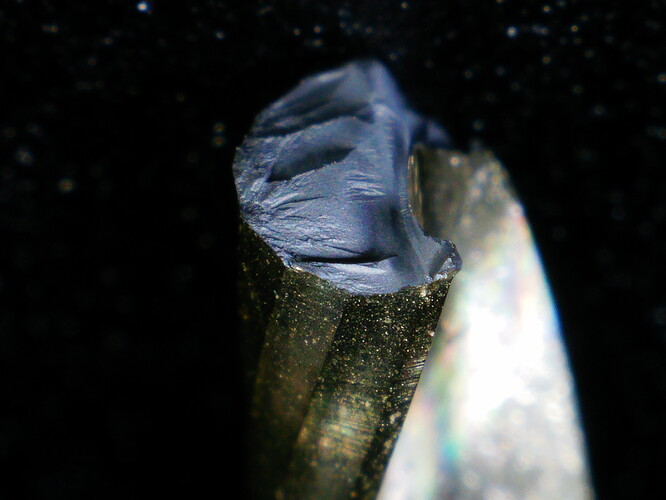

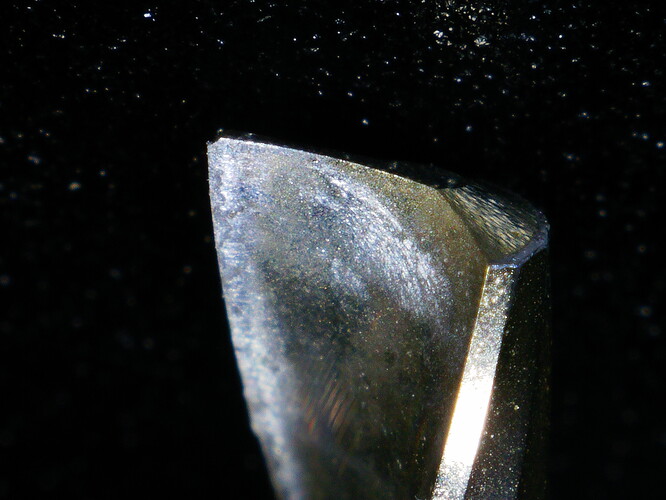

I’ll have to re-test most of these except of course the Carbide 3D endmill, which is the only one that broke. Here are some more shots of the broken endmill:

The only conclusions I feel I can make right now are:

- The CNCFraises, DIXI, Sorotec Alu and Sorotec ProAlu endmills all left pretty decent surface finishes as-is

- The CNCPlus 102-30, Sorotec Alu-B, Janpo 1MEM all left pretty meh surface finishes

To save on time, I might only bother with the first set of endmills when I re-test.