The main thing I’m hoping for with the accelerometer data is that some endmills will require less force than others to make the same cut, due to sharper edges or less friction. That would then show less vibration. Or maybe rigidity of the endmill could be a factor.

What are you cutting and how?

So I tested a bunch of endmills:

“Why are they all Cncfraises”, you might ask? That’s because right after I started cutting with a DIXI Polytool 7561 endmill, my accelerometer died. I saw that the light was off, so opened it up and discovered that the cavity that it sits in was filled with chips, which presumably had shorted something. I’ll need to solder up another one or replace my Teensy (in case the short broke it somehow).

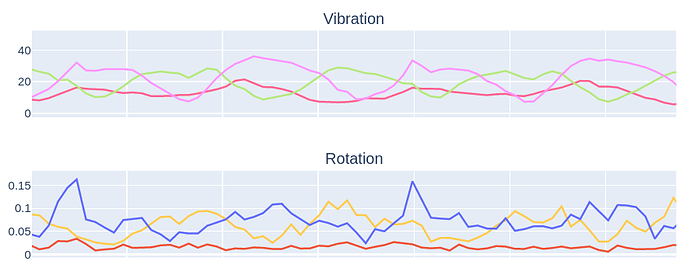

Good news is that it looks like there is a point to all my testing. If I look at the last loop of the spiral path, I can see that the level of vibrations are pretty different for all the endmills:

- EVOMAX

- FC1DA3008

- FDC1DA3008EVO

However we know that some of this is up to where the machine happens to be at the time, so to exclude that, I compare the lowest levels of vibration on Z only, in which case the results are:

- EVOMAX: 7.26

- FDC1DA3008EVO: 12.01

- FC1DA3008: 13.68

So the EVOMAX endmill has substantially lower vibration than the other two, indicating that the endmill does make a difference and making me feel much better about all the effort I’m going to.

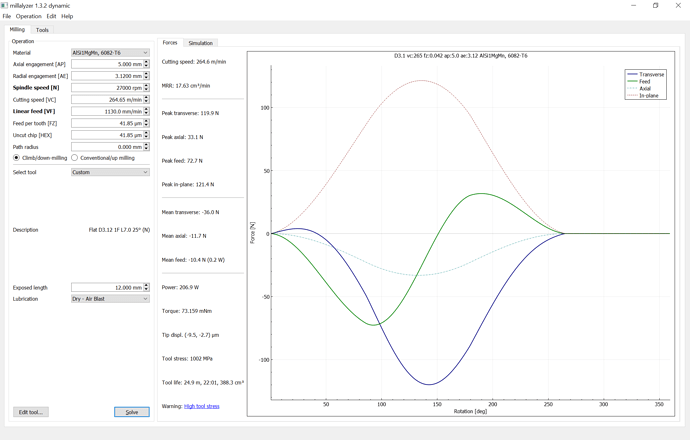

25mm square rounded pockets in 6062 or 6081 Aluminium (can’t remember the alloy) using a Solidworks CAM Volumill toolpath, 5mm ap, 3.175 ae, 27k RPM, ~1130 mm/min feed rate.

Are those all the same helix angle?

The helix angles aren’t specified but eyeballing them next to each other, the EVOMAX has a steeper angle than the other two. Both of the other two have the same angle.

So the Evomax is spreading out it’s pulse of cutting force over slightly more time?

Hmm, I’m trying to wrap my head around the question but it doesn’t make sense to me. The amount of time spent in the cut is defined by the RPM and chipload, no? With 27k RPM, it takes 2.2ms to make a rotation, regardless of the helix angle. Then, how much of that 2.2ms rotation is actually spent cutting is defined by the angle of engagement, which is a function of the endmill diameter and feed rate.

My guess is that the helix angle would only affect the velocity at which chips are evacuated?

I think the difference is that, over the depth of the cut a more helixed cutter will be engaged somewhere in the cut for a larger angle of rotation, starting with the tip at the bottom and ending with the last bit of flute in use at the top of the cut. The ideal with a deep cut being to have some bit of one or more flutes engaged all the time.

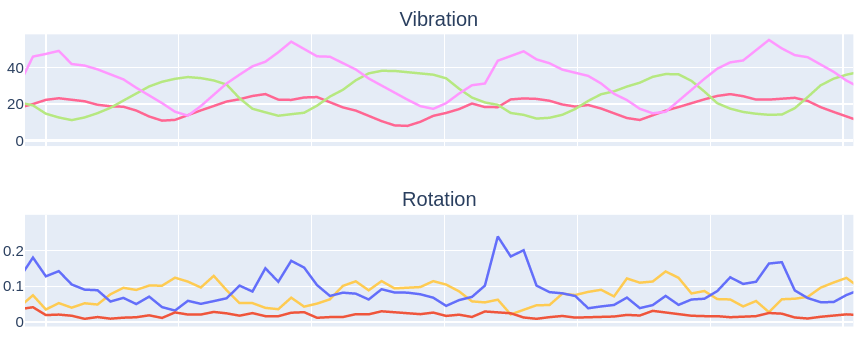

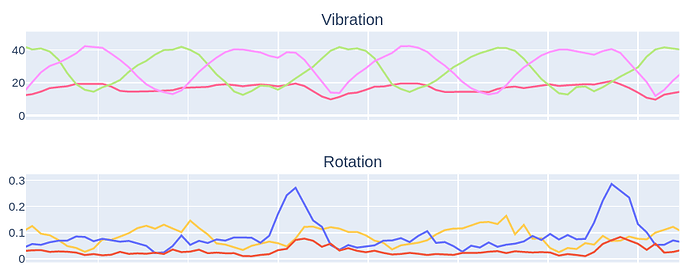

Tested 3 more single-flute endmills:

Looking at the same vibration troughs and combining with the ones above:

- Cncfraises EVOMAX: 7.26

- Sorotec Alu: 8.02

- Sorotec ProAlu: 8.23

- DIXI 7561: 8.96

- Cncfraises FDC1DA3008EVO: 12.01

- Cncfraises FC1DA3008: 13.68

I don’t think I’m going to continue using these toolpaths though. The chatter seems okay when I’m in the room but that high-intensity ~85Hz vibration travels really well through the walls and I don’t want to bother the neighbours too much. I’m going to be using multi-flute 6mm tools for most of the grunt work anyway.

That would require an unlikely 63 degree helix angle. With a more reasonable 25 degrees it probably looks like this.

@Moded1952 Is it possible that the cutter impacts are acting as impulses exciting workpiece/machine resonances (“ringing the big bell”)? Maybe measure the machine’s impulse response?

@spargeltarzan’s calculator predicts “High tool stress”. Do you think that overheating is also causing and/or contributing to the endmill damage?

Earlier, at 30k, it was doing it even more, so I dropped the spindle RPM to 27k and it’s still a problem. So I don’t think it’s that.

Sorry, I derped when I gave you the AE earlier. It’s 0.3175, not 3.175. Divide by 10.

It only takes one impact to ring a bell.

Yep, but hit it 27,000 times and that bell knows it’s been rung ![]()