As you will see, this is very much a work in progress ![]()

I wanted to try my hand at some “industrial automation” to see how it compares to the hobby electronics I am used to working with. Oh boy, it’s a different ballgame. The logic and all that appear to be the same but the components and integrations available are very different. It seems the tradeoff for reliability is convenience, size, and price ![]()

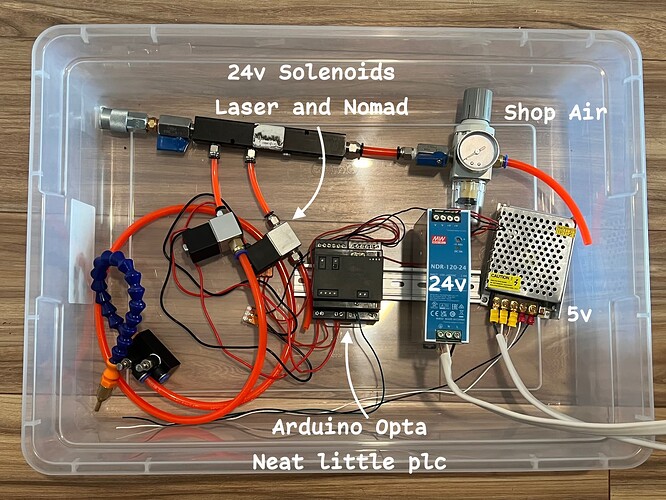

Here is my little “project box” as it sits:

The heart of the automation is an Arduino Opta. This is a neat little plc with little to no documentation. It is also rather expensive for what it is…but it’s a great introduction to the world of plc. I can program the thing with ladder logic and all that fun stuff while also being able to fall back to an Arduino sketch if this whole plc thing isn’t for me.

(Sidenote, this opta was also a test drive for another controller in the arduino pro lineup. After this evaluation, I’ll likely go with the Arduino Edge Control for a relatively advanced indoor hydroponics farm. Peppers all year round baby ![]() )

)

The Goals:

| Objective | Mode of operation | Notes |

|---|---|---|

| Toggle air assist | Auto w/ manual override | 24v Solenoid |

| Toggle shopvac | Auto w/ manual override | 110v Relay |

| Toggle mql coolant | Auto w/ manual override | fog buster mini w/ iso mix: PWM needle valve |

| Toggle measured drip coolant | Manual w/ auto shutoff | Experimental: peristaltic pump |

Air Assist: Pretty straightforward. A two way solenoid opens and closes to allow air through. These are cheap, reliable, and easy to work with. I am only running ~30psi to this side of the shop so they don’t have to do much work when toggling.

Shopvac: Another easy one. Just a relay that switches 110v power to the vacuum. Leave the vacuum “on” all the time and just toggle power as necessary. (My vacuum also has a wireless remote so I could use a wireless signal to toggle…but I’ve come down to the shop at 3am and found it running. Seems they don’t handle interference well.)

mql coolant: This one is trickier. The mql on the fogbuster mini works great, uses very little coolant and makes a world of difference in cutting aluminum. That said, it’s a PITA to get the coolant to air mixture just right and you need to close the valve after every run or risk slowly evaporating/dripping out your coolant. This means you have to do the fiddly bit of setting coolant/air ratio every time you run a job.

The solution? I think I can find a small pwm controlled needle valve to open a precise amount when the job starts and close when the job finishes. We may also get away with an experimental solution of a peristaltic pump to dose iso into the line…we’ll see.

Measured drip coolant: This would be for coolant like tap magic or some other cutting oil. I can use a peristaltic pump to effectively dose out the coolant as the job runs. These pumps are very effective at dosing small volumes consistently. I am going to run a thin silicone tube down to the collet nut and use a trick I learned from @Gerry to pinpoint the lubricant delivery directly onto the shaft of the cutting tool. A bit of heat shrink tubing to make a soft but effective “needle”. (See Nomad 3 Air Needle - #3 by Gerry)

Stretch Goal: There’s a good bit of “potential” automation here but most of it would not be used at the same time on the same job. That kind of kills the whole “Auto” part of these setups. I’d like to set up a little script that reads my gcode along with comments and “decides” which set of automations to use. If I’m cutting aluminum, it should do mql and air assist. Wood, use the vacuum. Plastic, vacuum and air assist but no mql. etc…you get the idea.

This should be very possible but It’ll take time to get there.

Lessons learned:

I have not worked with this kind of equipment before so I’m learning a lot as I go. The industrial stuff does not hold your hand and it certainly doesn’t care about making things easier for you. In a hobby context I could probably pick up a pre-fabricated board that takes 24v and has an i2c header to handle power and logic for all of the relays over a simple data signal. This kind of “smash all the functions into one board” product does not seem to exist in the industrial space, at least not at any affordable price.

All of the pieces are single purpose and it’s up to you to lay it all out and really plan your approach. I feel like it’s all pretty straightforward once you get the hang of it but the initial learning curve can feel pretty steep. Still, it’s been a great experience and really makes you appreciate all of the conveniences that come with the hobby market. It also makes you realize how damned fragile everything in the hobby market really is ![]()

Next steps:

- Get myself a few distribution blocks for sharing the power and getting the signal around. I am currently using wago lever nuts which work great but I’m trying to do this “right”. (See this post for what it should look like My new electronics enclosure)

- Get a proper enclosure to house all of the components and keep the metal chips away from all my hard work.

- Integrate some tool probing protections for the nomad. Not quite sure how I’m going to do that yet but I’ve got one of these…I figure I should be able to do something with it.

The intent here is to control all of my shop automation from a single cabinet. That means a lot of stuff was left out in this post. Things like the air compressor(s), fiber laser, injection mold machine, lighting, hot boxes(for silicone/resin work), etc…turns out there’s a lot to do in a shop and this is going to be quite the journey.

The end: (well, just the beginning really)

I suck at this kind of thing at the moment but feel free to ask any questions and I’ll do my best to answer them. More likely, someone else with more experience will answer aka @Julien and we’ll both learn something, so please do ask ![]()

Also, if you think I really suck at a particular thing, please let me know how I can/should do better. For example, I crimp my cables now…I’ve never bothered before ![]()