Hey, Mike. How are you testing the stiffness? Or, in what ways are you noticing it? Would you say it’s definitely an improvement?

When trying to move the carriage, it clearly moves a bit with force in the Y+/- direction, and is much more firm in the X+/- direction as it’s set up now. Measured? No. Direct comparison with a bit of qualitative guesstimation? Yes.

Good enough for me to add it to my to-do list…unless someone comes in with some subjective praises for a double belt upgrade.

Mike so did your order from RepRapWorld or AliExpress? Is the Kevlar 2mm pitch? I have concern with the steel and the lateral load it applies to the steppers. Time will tell by the users.

Why do you think the load is different if the tension is the same? You certainly COULD make the tension higher. All I’m looking for here is less stretch over time causing me to need to re-tension/recalibrate.

Ordered from reprapworld- netherlands.

My thought or theory is if the belt is less flexible as it goes around the idlers and up around the stepper the side load will be increased. Without handling them myself I only have what I see in my head, or theory. Someone mentioned that the moving the carriage, with power off, takes more force. Unquantified but to me that incremental resistance is created somewhere. That extra force maybe what helps reduce the chatter being experienced by removing some backlash. Maybe I’m all wet wouldn’t be the first time.

Reprapworld has confirmed the kevlar is 2mm pitch. The 2 in GT2 is for the pitch for those like me who didn’t pick up on that.

It’s my understanding that it’s 2 for second generation and that there are GT2 belts with 3mm pitch.

Yes, typically if you see GT2 it means second gen. If you see 2GT, that means 2mm pitch (most likely gen 2). But it gets mixed up a lot.

RepRapWorld order came in today.

Kevlar vs Steel vs Fiberglass. Got enough to spare for just in case and some future projects.

Probably be a few weeks before I install them (Kevlar). Plan on tearing down the S3 for maintenance, squareness and tramming.

Wow, nice photo of them. Do you have steel ones currently installed or you have yet to switch from the fiberglass ones?

I have the stock Carbide3D (fiberglass) belts installed at the moment.

I hear those Kevlar ones are bulletproof

Sorry, couldn’t help myself,

Dan

I went ahead and ordered some steel ones so we’ll see in about a month how they perform. I’ll measure positional accuracy and consistency beforehand and then try some speeds and feeds with each one.

I got my steel belts (2 rolls) in from Aliexpress a couple of days ago have not installed yet but comparing them to the stock fiberglass belt here’s what I see. The steel belt is marginally stiffer when bending then the stock. But I could see zero stretch with the steel. As far as wear goes to the stepper motor bearings I don’t see much of an issue as long as you properly tension and not over tension the belts. Belt life will have to be observed over time. But about $40 for 20 meters of belt I think I could afford a little less belt life for increased rigidity. I will try and get them on my machine this week and give an update.

Extra care needs to be taken with installation due to thickness and guide wheel interference

Besides that’s I’m testing now at 1000ipm / 25,400mm and 2000mm accels. No sign of slipping or skipping

Awesome! Thanks for the tips.

Have you measured backlash? Is it worse?

Received 3m of steel, and 3m of kevlar from RepRapWorld. I already have some steel core on the X axis. I installed kevlar on the Y axis this afternoon. They are more flexible than the steel core, not as flexible as the fiberglass.

I did notice that there seems to be a lot of defects in the kevlar belts - I’m not sure they’re anything more than cosmetic, but they exist. I don’t see the same issues on the steel belts. I wasn’t able to find a long enough section on the 3m I ordered to get two segments ~1m for the Y axis without them, so I guess I’ll found out if they’re a problem.

Set grbl steps to stock defaults and cut very consistent to stock, held 5thou tolerance easily and 0.001 repeatability

However, not perfect testing due to my linear bearing leaving artifacts in the parallel surfaces. The steel belts could be accentuating this due to increase in stiffness.

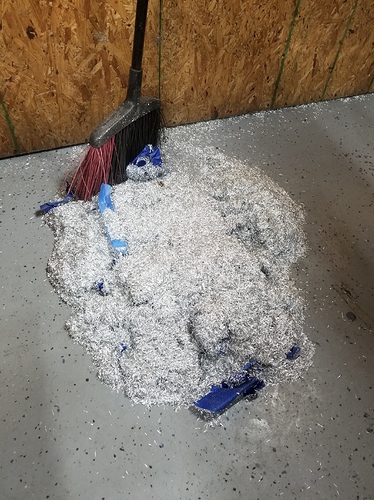

I ran them for about 6 hours with heavy 8mm single flute rough and finish 50-150ipm and up to 10mm doc. No sign of any delamination or separation. I think about 8lb material loss, check out that chip size!

Seat of the pants stuff felt like there was a real increase in quality of movement. Machine still has a tendency to slightly chatter on entry and exit of X moves when deep adaptive and some speed

Hey mike, any info on the Kevlars?

I could only find them from Reprap as well, any other supplies?

Steel belts have been golden, zero delamination issues for now.

Not yet, have a couple projects to do, but work has been a bit too busy to get to them.