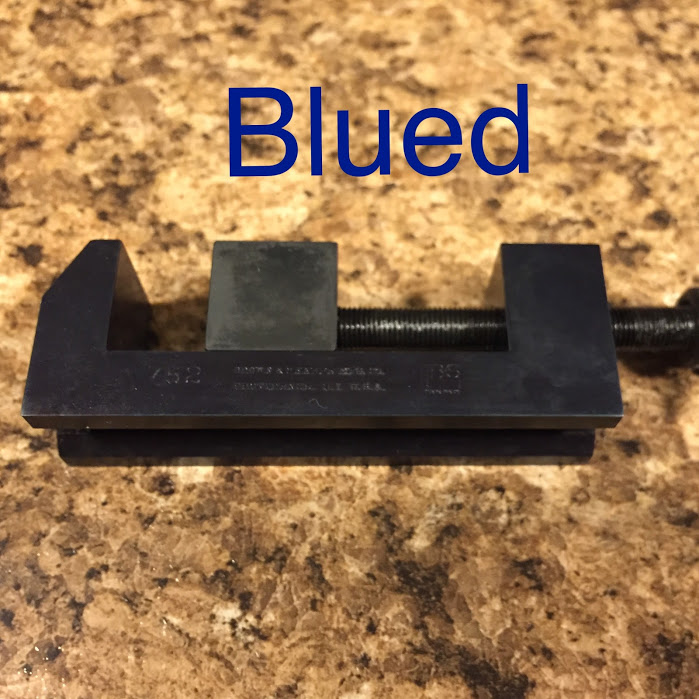

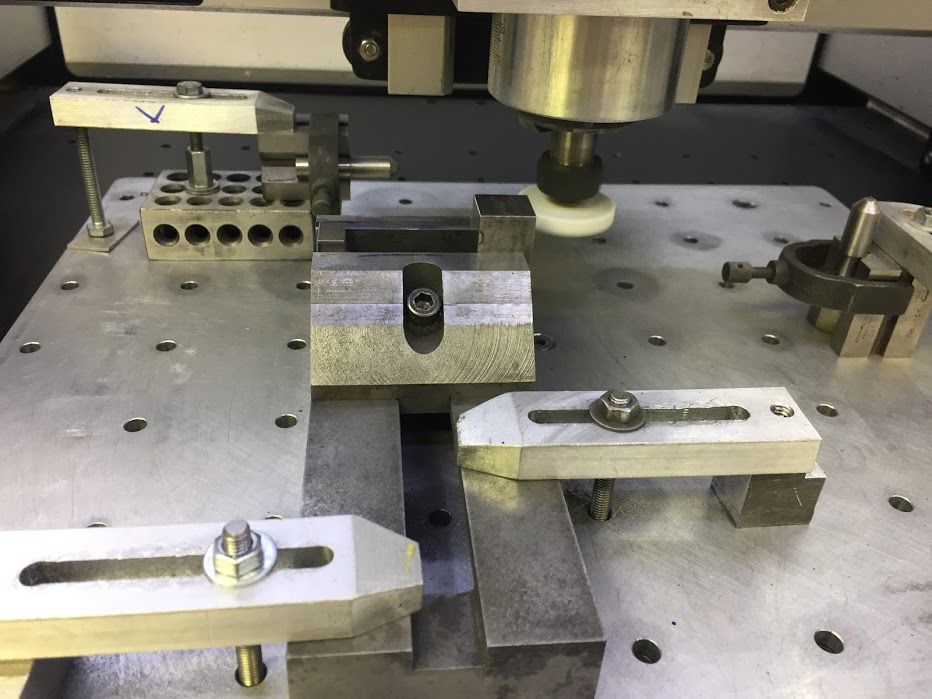

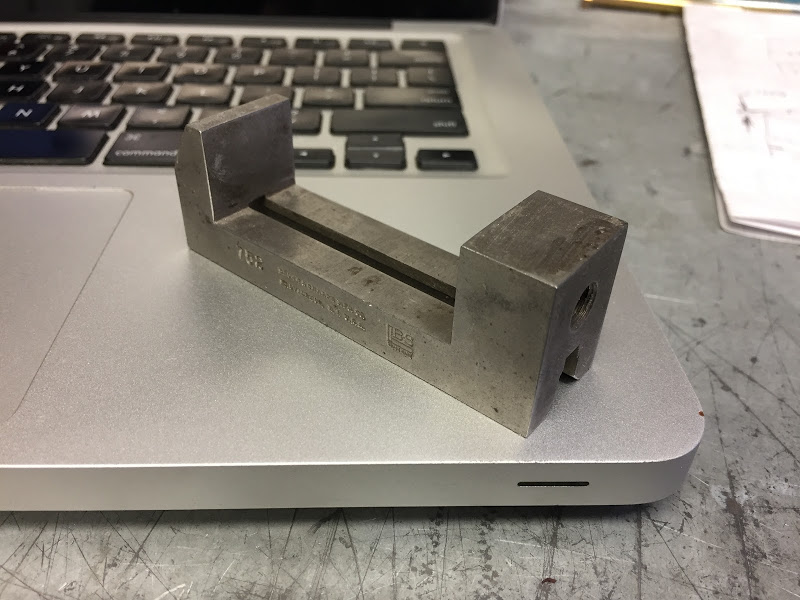

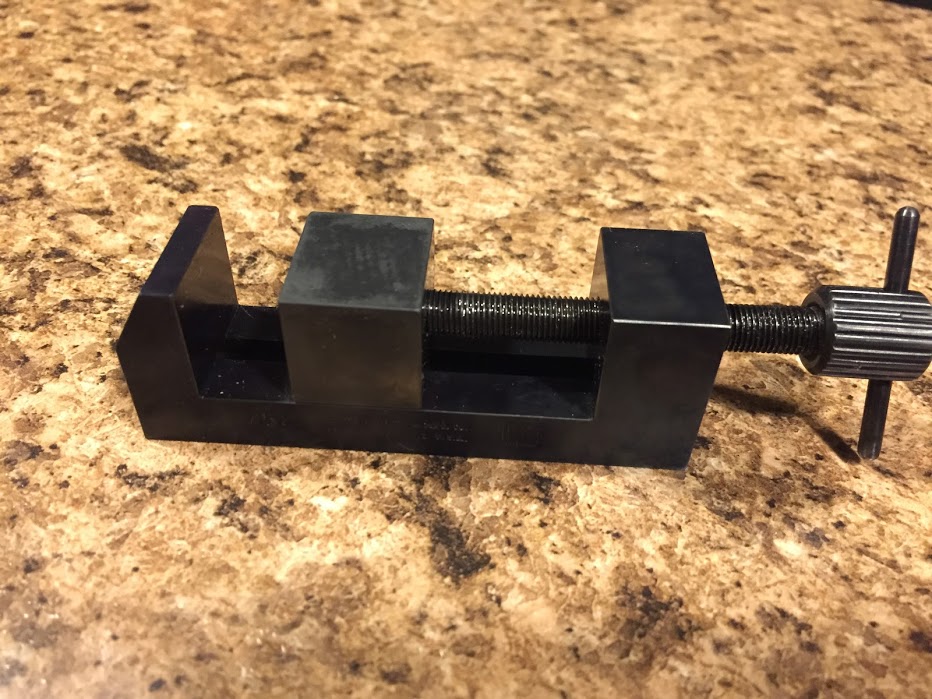

Here is a hardened steel (Rc 65) Toolmaker’s Vise that I finished Ground on my Shapeoko:

Note: ALL surfaces are ground square, parallel, etc. (My tolerance was +/- 0.00025")

Check out my IG for lots more photos and videos (JPL_Richard)

If you’re interested in the story, continue reading:

About 30+ years ago, I was given an unfinished 752 Vise Body. It was pre-machined, heat treated and tempered to 65 Rc. Missing was the jaws, lead screw (of a proprietary thread pitch), and the jaw retainer. When I was working in a machine shop I could never find enough (personal) time to work on this vise, so it sat.

Along came the Shapeoko 3 and while I knew I could make the missing jaw parts, the lack of a lathe and grinder kept this project out of reach. One day @ApolloCrowe (you remember that guy?) told me about a Tool Swap meet. At the show, I found a thread gauge and found out the proprietary thread was actually a 32TPI…and THIS moment was the starting point.

If I could make the lead screw, maybe I could tackle the rest of the parts…even the grinding (on the Shapeoko). I determined that the thread OD was somewhere between 5/16 and 9/32. I bought a 5/16-32 adjustable die and practiced. on some soft steel. When I finally figured how to make the correct size, I then I purchased some grade 8 bolts (to use as bar stock). I annealed them to a soft state and then threaded two of them, and kept the best one. I then re-heat treated it and tempered the lead screw to 40-45 Rc (Rockwell C Scale)

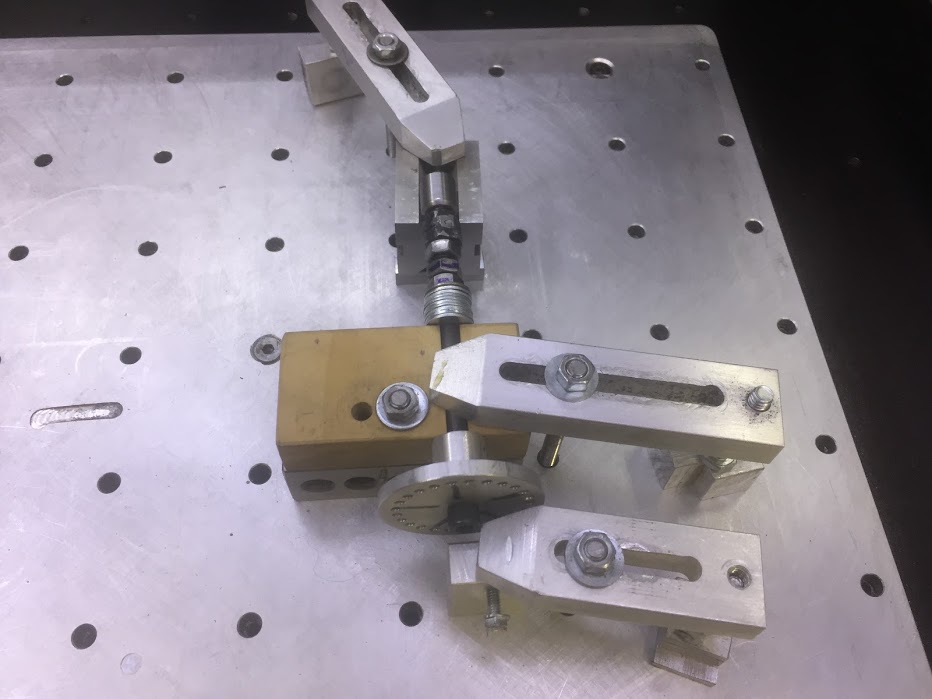

Using an old index tool I made last year, I used it to mill a straight knurl on the lead screw as will install a ball plunger to add tension to the dowel pin handle.

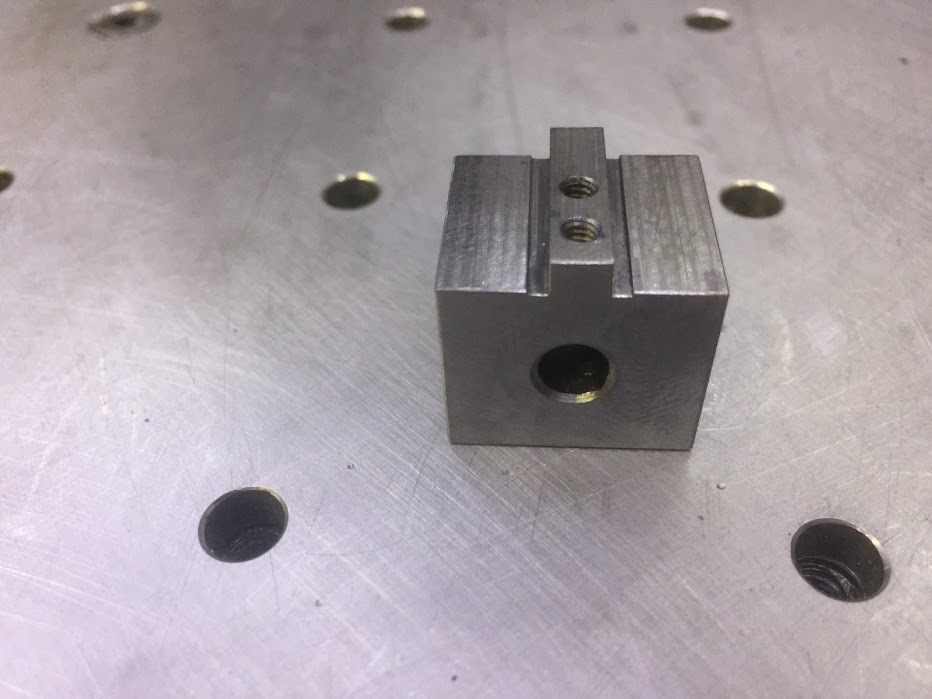

Now I was ready to tackle the vise!! I have seen far too many toolmakers who have lost one or the other jaw, I also decided to forgo the two piece jaw design of a single jaw (longer that the short jaw, but shorter than the stand long jaw. I purchased a foot of O1 tool steel, and using my power hack saw (another Shapeoko project) I lobbed of a piece. I decided that 0.010” extra material all around was enough to allow for grind, so I designed the finish part in Fusion360, then scaled the part to 101.14 percent.

Once the jaw was finished machined I made a redneck Heat Treat Oven out of a few fire bricks. Heated the material to 850ºC (1560ºF) I then tempered it at 400ºF to Rc 62-65

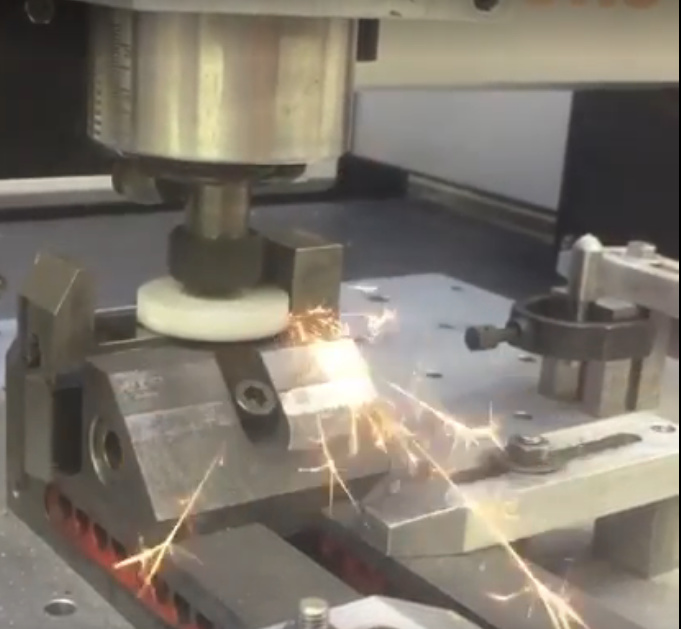

Grinding: I purchased some 6mm shank Grinding wheels (40mm Dia x 10mm Thk) Grit unknown, but I guesstimate 36 grit. $1.30 each.

I set up two diamond wheel dressers. One to dress the OD and one to dress and dish the bottom

Setting I picked:

Speed: 12,000rpm

Feed 11 to 20 inches a minute (travel)

Down feed between strokes 1mm

Depth of cut: 0.002” (max)

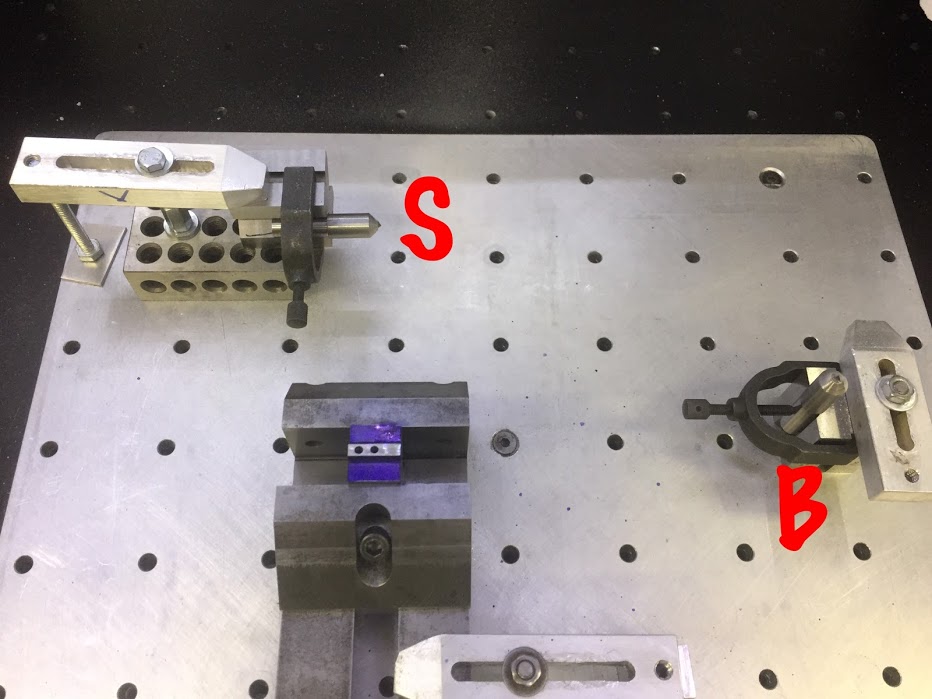

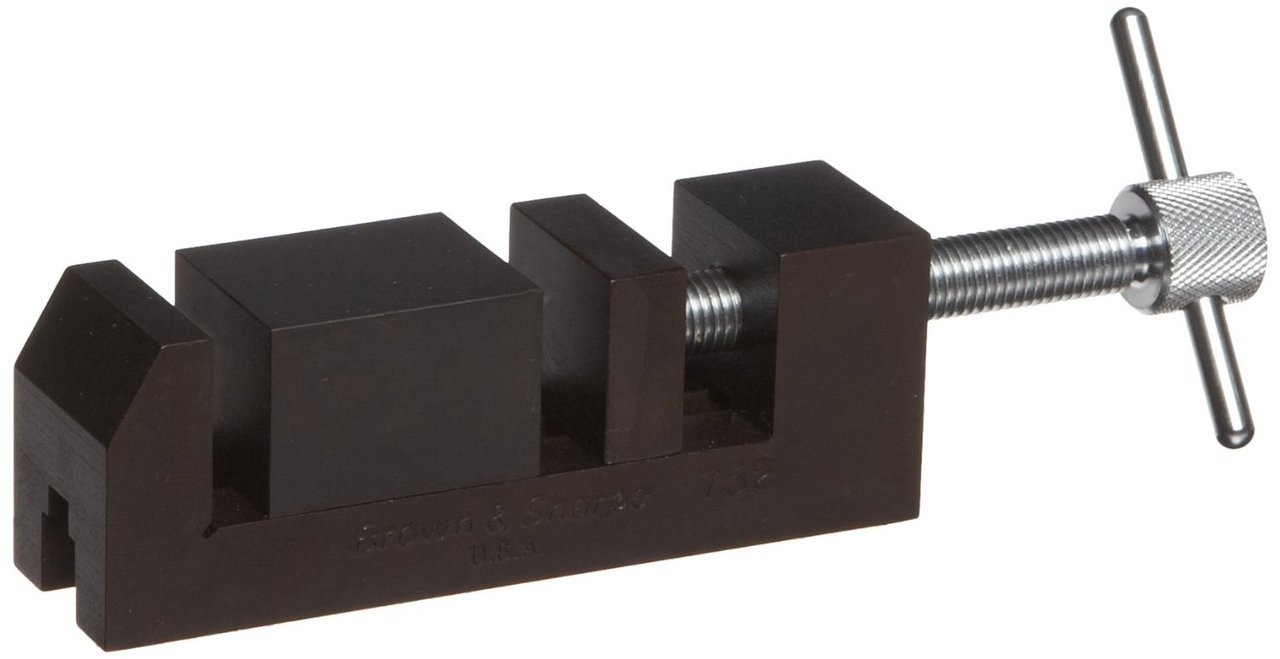

Commerically available B&S Vise: (Note the new corner relief for the jaw)

My Vise (Ground to within 0.0003") Ealier designs never had a corner relief, they (and mine) were ground square)