I am struggling with CC, lack of intuitive layout tools and having to create shapes as guides is really frustrating. Carveco maker seems like a better choice but I am not sure how it will work with carbide motion. I was told that bit setter would not work with imported files from maker, does anyone know if this is true and if it is what is the work around? I am brand new to cnc and don’t really understand the difference between bit setter and bit zero.

What is that you are trying to do that you are having trouble with?

Folks who are willing to make monthly payments seem to do well with Carveco Maker, and it should be able to output G-code for tool changes — it would just need a suitable post-processor.

The BitSetter and BitZero accessories are complementary:

- the BitSetter manages tool length offsets, so one can have multiple tools in a single file

- the BitZero allows one to set the origin relative to the corners of rectangular stock, or the surface of flat stock, or to probe a hole in conductive stock — since it is more accurate with a probing pin, it is nice to have the BitSetter to facilitate tool changes

We have some Carveco users here on the forum but they seem to few and far between. We have a lot of F360 and Vetric users. The Vetric products are said to be very intuitive and are made for carving wood. The F360 has a very steep learning curve and is quite versatile but without paying you can get only one tool path at a time. Vetric Desktop is limited to 24" x 24" projects. The next level up can do full Shapeoko dimensions on any machine they make. Then at the top of Vetric is Aspire. The good thing about Vetric is if you start with Desktop and out grow it you only pay the difference between Desktop and the next level up. You get a permanent license for the version you buy. There is a fee when the come out with a new version but incremental updates for the version you have is free. Currently I think they are on v11. So someday when they go to 12 you will have to pay for the upgrade or simply keep using your v11. F360 pay is monthly and is cloud based. Not sure what model Carveco uses but lets face it there is no free lunch except Carbide Create.

Im am just learning CNc but have been designing furniture and cabinets in sketchup for a couple years. I’m trying find something a little closer to that in being able to use guides, easy measurements and centering objects on objects. CC seems like it does not do that and the videos I watched left some info out and then just had Kevin saying “make mistakes, it’s how you will learn”. That’s not really my way of learning, though I know I will make mistakes it is the last thing I want to do, not the first. That being said the projects I have done with CC and the new version of CM I enjoy the prompts to change tools and using bit setter in between. How would I export for a program like carveco to carbide motion and still be able to use bit setter and bit zero?

I use Carveco Maker This is the cheapest version which is only available on a monthly payment plan of $15 plus any relevant taxes in your location. There are monthly plans for the higher specified versions and they can be purchased outright as as well. It includes the post processors for Carbide 3D in inch or metric units. It creates an industry standard .nc file which Carbide Motion can cut. They have several really interesting toolpaths and the ones I use for my 3D models are circle in a box with roughing in an optimised circular pattern. For a discussion of how and why they are frequently more useful than raster carving, send me a message.

If you are familiar with any other graphic design software for images or design, then Carveco uses an interface which follows many of the conventions of design language. I don’t remember if they have a free trial period but unlike Vectric software, there are no limits to what you can design or save nor do they limit the size of your project. Just start a plan and then you can drop it before the month is up so effectively, it is a trial for just $15. You also get to access all of their training and tutorial material for free. They also provide a library of 3D models and vector models to their users. Their support system is responsive and they have been flawless in the few years I have used Carveco software.

I have found the software hugely capable and my latest carve is this one. It is olive wood sized to 140 x 140 x 50mm and the model is 18.29mm in depth. It required no sanding but the surrounding wood was sanded to 3000 grit and the whole workpiece was finished with a light coating of beeswax.

Vectric has ruler guides that can be pulled along either axis and placed wherever you want. Snapping is configurable to those guides or other geometry.

Oh, and @gdon_2003 V12 is scheduled to be released this month.

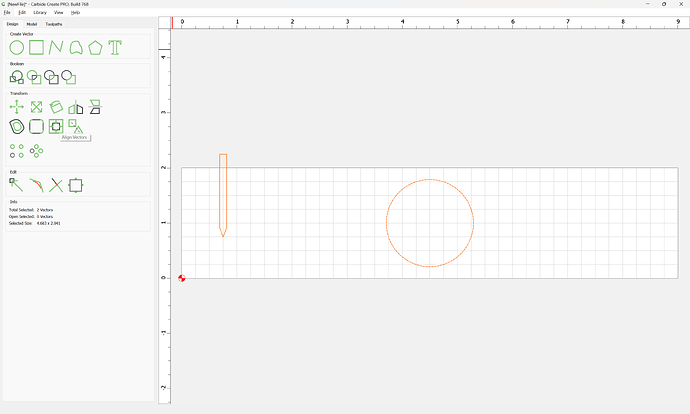

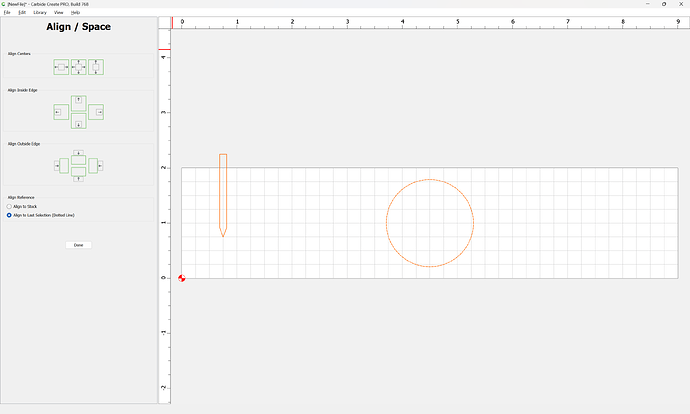

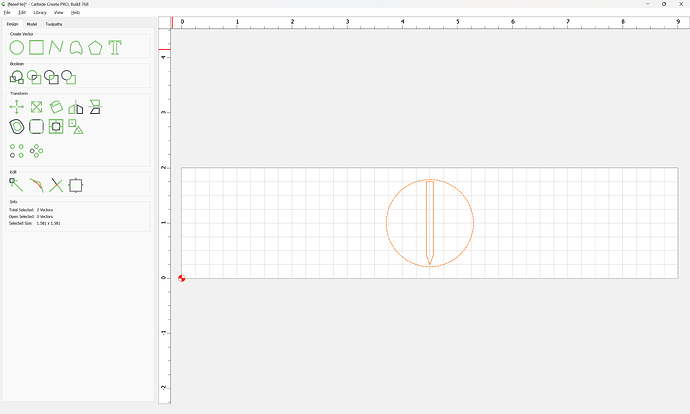

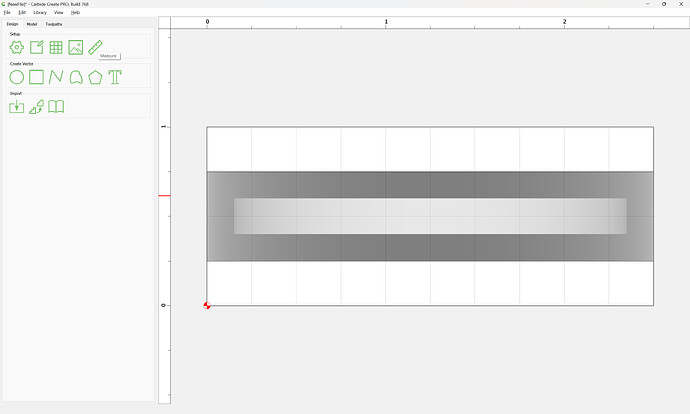

You can do centering against objects — the most recently object is the “key object” (indicated by a dashed highlight):

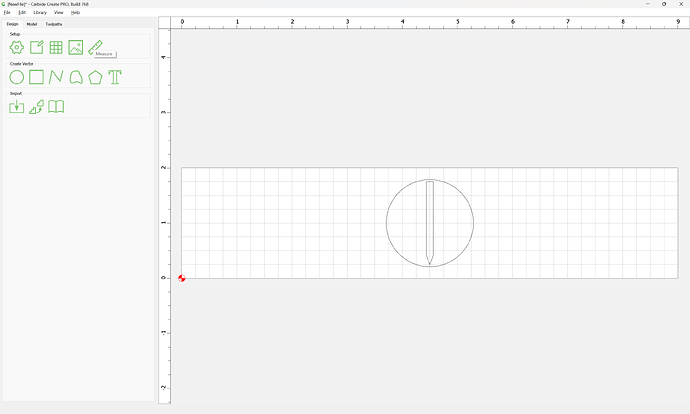

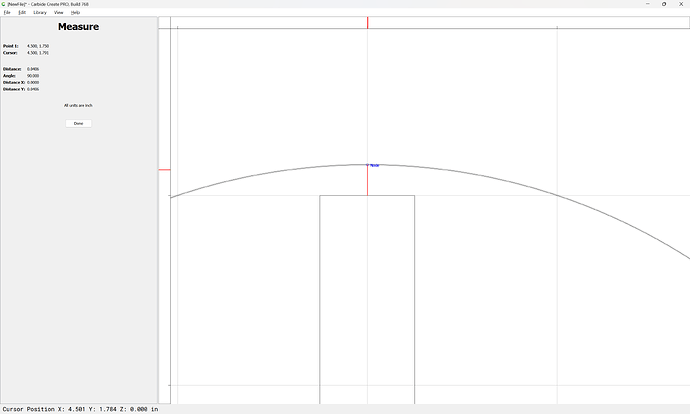

For measurements, there is a tool:

I’ve written up a bit on Carbide Create at:

https://willadams.gitbook.io/design-into-3d/2d-drawing

and

Does that help?

If not, ask specific questions and we will gladly do our best to assist.

Using a BitSetter is simply a matter of enabling toolchanges in your CAM tool by selecting an appropriate post-processor — that’s something which Carveco tech support should be able to assist with.

Using a BitZero is pretty much all in Carbide Motion — but you will need to select points of origin which are at a corner so as to be able to use it for X and Y.

Could you provide an example of a cabinet design with dimensions and notes on the sort of joinery you wish to do? I’ll gladly work up a set of step-by-step instructions.

Thanks for the input, I did want to get vectric but the price was just too high for me, at least for now. That is why I was looking at carveco, seems to have all the capabilities of vectric but for a much lower cost. I recently had to end my career in healthcare and am trying to make my woodworking my main source of income. All that to say money is tight and the CNc was an investment to have a “second set of hands” in my shop

Thank you, that does help.

Thanks for your response, I have decided to go with carveco. If I am going to take the time to learn a new software this one seemed like it would do what I need it to and the price is good. Now that the decision is made it’s just time to learn the software!

That’s great to hear!

If you’ll provide the specifics of a cabinet design:

- overall dimensions

- features

- stock thickness

- joinery options

we’ll gladly walk through making that, and if you wish, work up an automated tool for it which will make a DXF which you can then import into the CAM program of your choice.

Good to know. Best of luck with Carveco. ![]()

I use Carveco without any issues. It has the right post-processors for the generated G Code, which is what really matters.

Just seems really hard to lay things out in CC. I’ve been learning Carveco and it’s got a lot more tools but I do wish CC was a little more cad like. I used sketchup and even shapr3d a little so I’m used to having easy guide lines, easy measurements etc. I’ll still be playing with CC also

There is a measurement tool:

and usually, for complex jobs, I will create a layer just for measurement aids and draw additional geometry on it and show/hide it as necessary.

If you’d provide an example of a project which you are having trouble drawing we will gladly walk through it with you.

This topic was automatically closed after 30 days. New replies are no longer allowed.