I do not own a CO2 laser. I am not a patient man, and my end goal was to own a laser, so I could say pew pew.

But now that I see that it cuts phone very well, I will make some inserts for some of my tools and toys.

I do not own a CO2 laser. I am not a patient man, and my end goal was to own a laser, so I could say pew pew.

But now that I see that it cuts phone very well, I will make some inserts for some of my tools and toys.

Yes, I do have a CO2, I have not used it since we moved. I don’t have the needed fume exhaust as I did in our old home. CO2 laser produces much more fume than laser diodes. The speed depends on your project and controller board. You also have control over laser power. I think I’m going to offer my CO2 for sale if you know anyone who would be interested.

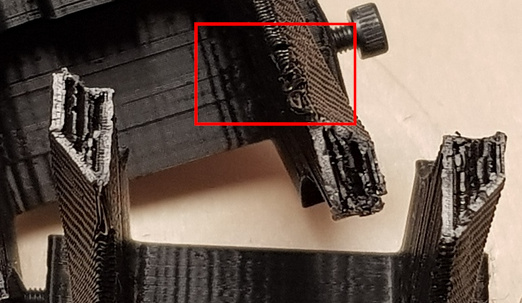

OK, so, started installing the JTech laser last night. I only installed the dust boot mount option. It was a bit tight but went on OK. Then as it was late I called it. Today went into the shop and saw that the mount had split clean in 2. I don’t mean a crack I mean complete through break in half. it was just held in place by the little screws otherwise it would have just fallen off. Some pics;

I don’t know much about 3d printed parts but looking at the cross section of the break it looks like a really weak part.

To the 3D printer guys and/ or engineers here what do you make of it? Why did it break overnight because it certainly was not broken last night it would have been obvious. Is it a temp expansion thing??

I’m waiting for JTech to get back to me.

Ouch. This is plain weird, I have never seen that happen in any of the prints I have done over many years. I dare not think that it was broken and they just glued it and the glue let go ?

Any pets (or kids) that might have done this and not confessed yet ?

Anyway this is a poor print, regardless of the break. That part right there shows that something did not go well when they printed it:

maybe not a coincidence that it broke not far from that squiggly mess?

Anyway, hopefully they’ll make it right.

Yeah,

That print shouldn’t have gone to a customer.

It’s hard to tell in the pics but has it fractured along the layer line in that narrow part of the body?

(layer line is the horizontal layer of filament that gets laid down by the nozzle leaving visible ridges like sedimentary rock on the outside)

Nada! twenty characters!

Not sure do these help. Also looking at the break it looks as though its not quite solid has voids in it, the dark areas in the break.

Hmm,

May I say “Eeeeew!” it looks like the break is actually across the layer lines not a shearing between layers which is quite uncommon. 3D print is like wood, it has very little tensile strength across the ‘grain’ which are the layer lines and reasonable strength in both directions of the plane of the layers. The part designer is responsible for thinking about how it will be printed and how to deal with the weak axis.

What’s more concerning is what appears to be a quite severe case of the wigglies and the stringies in that print. The wigglies are so bad that they looked like the layer lines to me and the layer lines looked like a textured filament. The number of under and over extruded parts (Julien identified one above) is sufficient that I would have checked the printer and slicer settings to see what I had done wrong with that part.

@Julien what do you think?

No obvious sign of glue.

I sell 3D printed objects for another hobby and those prints are disgusting, these should never have been sent to a customer. Also do they mention what plastic they use?

I guess we all agree that this is a botched part that went under their QA radar, I’m sure they will agree and send a replacement soon. Still surprising that it would spontaneously break like that…that’s a mystery to me.

Indeed,

It looks like the design has the layer lines in a sensible direction and could work if printed well without obvious defects, so a well printed replacement should work a lot better.

Yes, but it was very late last night may be that’s a perception issue. It was a snug fit but pushed onto the aluminium mount. I did up the screws and attached the laser, gave it a little wiggle to check its security and then left it for the night. This morning went back to it just as I was removing the laser noticed that things were all loose then it became obvious why. It is possible it was broke last night and I didn’t notice.

When 3D printed plastics let go under strain it’s frequently a complex process. It looks like the print had a number of deficiencies which would give it many areas of existing weakness and stress concentration.

It is likely that as you tightened it up one of these existing weaknesses started a crack propogating through the material. These can happen quite quietly sometimes and don’t always go the whole way immediately, depending on the plastic they can continue to creep if the strain is still applied.

I’ve cracked at least one prototype spindle dust boot by over-tightening the M4 locking bolt and exposing the stress concentration I accidentally designed into it.

I’m still waiting on a reply, probably Monday now. I’m sure they will sort it, just a bit frustrating as its back on hold and its not as if they are local to me! One thing I will say is that my original order was for the standard mount, then I changed at the last minute, maybe they grabbed one from the rejects pile by mistake!

I remembered I still have the printed parts I got with my JTech back then, I never used them (just because I wanted to design a custom support)

Here’s what the part I got looks like:

Better but it does have the squigglies in the same place (but as @LiamN said, the design is printed in the correct direction, so apart from not looking great there should not be any functional impact).

Your part looks thicker at the failure point. The one I have does not have a box like profile, its sloped so there is less material there.

Yep,

That has the look of a part that is being printed quickly to increase throughput. It looks like there were no supports which would need manual post-processing and take extra time. The fairly thick layer thickness is actually good for strength as well as print speed. The squigglies are an indication that the printer is being pushed beyond the print speeds that it’s really good at in the interests of overall print time.

Nothing really wrong with it, if it works, but it’s not going to win any prizes either.

You might have to wait a little longer. We’re all in the Houston area which is currently in the crosshairs of two Category 1 hurricanes (60 - 70 mph winds). Something that hasn’t happened since the mid 1900’s. It usually means lots of flooding where JTech’s office is and in the general area.

With two storms a day apart, the prognosticators are having trouble coming up with a decent forecast except the one that says, “Keep a chain nearby because its going to be a turd floater!” ![]()

Or you could just measure up the laser and spindle and machine out your own mount with your Shapeoko?