Morning guys

I’ve been talking with a couple of makers who mill aluminium and wanted to keep chips out of their axis as best possible. Usually when milling aluminium you won’t be using dust boots.

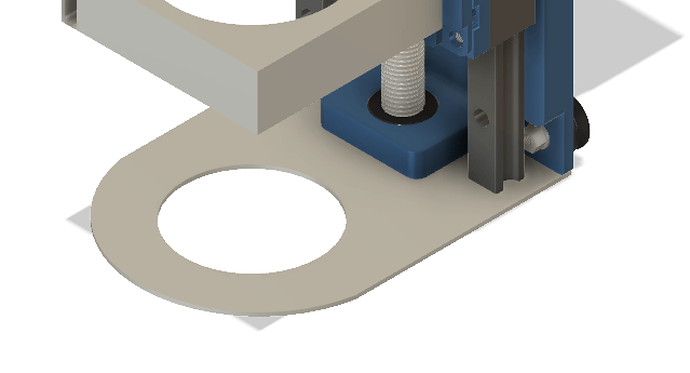

I’m looking into bellows, but in the mean time designed some adhesive chip guards. These mount to the bottom of the axis using a bit of double sided tape.

67mm file for the Makita

72mm file for the Dewalt

82mm file for an 80mm water cooled spindle