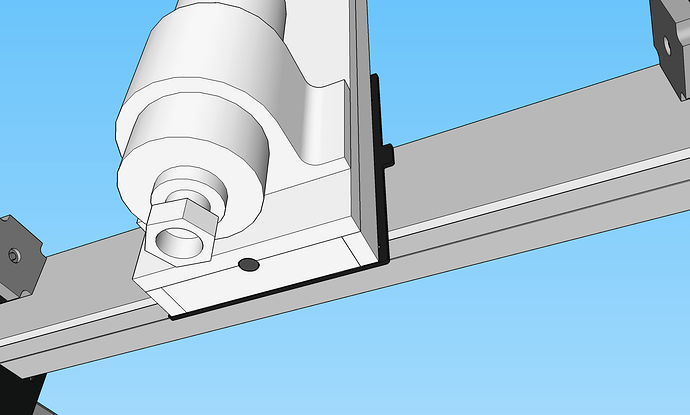

A little lubricant on the ball screw and blocks always helps. Other than that it’s pretty self serving

I was never able to open it, just tried again. Set up a new project. Could not import the file. File downloaded from your site has no file type associated. It shows up as an empty box in Fusion uploads.

Before you import it add the f3d extension. Just tried it all works

Ok

Next question, how did you save it? To your local machine or?

Yep on the mac…

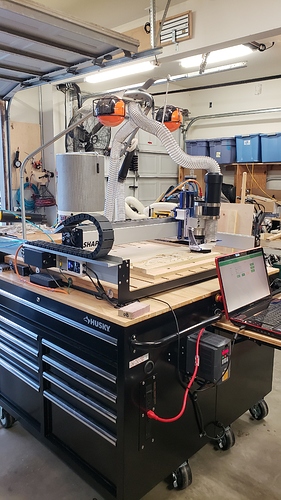

Luke, how much taller is HDZ compared with the stock assembly? I thought I saw the info somewhere , but can’t find it and I need to upgrade my enclosure.

cheers, Alex

Hey,

You need approx 270mm clearance from the top of your X rail.

Ta,

Luke

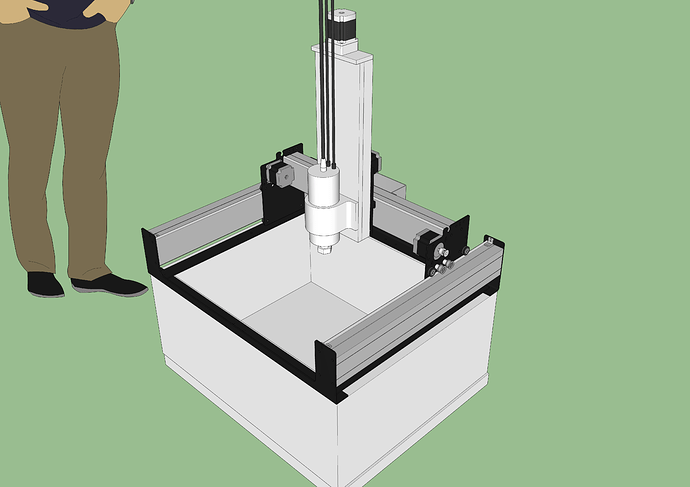

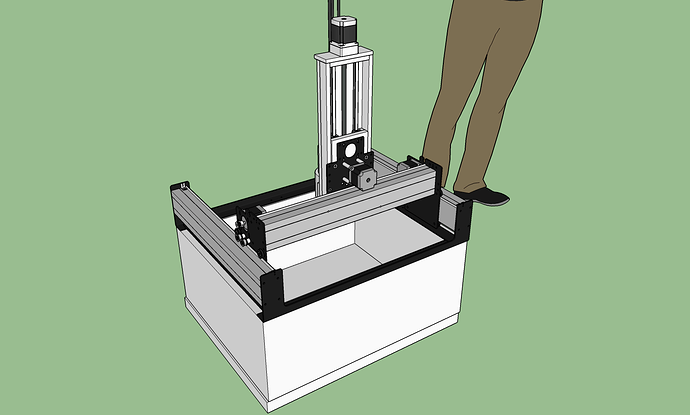

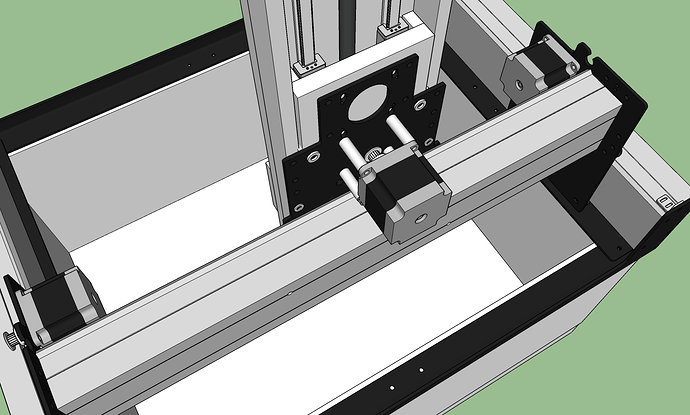

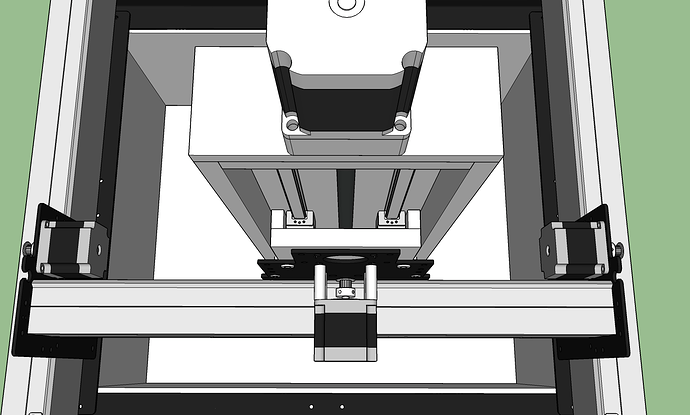

Hi, I’ve discovered the woeful inadequacy of the shapeoko z axis with a 2.2kw spindle. The x and y seem to be doing alright, but they don’t have to lift the spindle weight in the same way… I saw your HDZ ballscrew actuator while fishing around for a solution. I’ve been thinking a bit about it, and I wonder if anyone can tell me why I shouldn’t try something along these lines? Please bear in mind this a very quick thrown together model to demonstrate what’s in my head…

Advantages over conventional ballscrew mounting are:

- useable cutting travel all the way down. This drawing shows 300mm of travel

- better shielding of the sensitive parts of the Z axis from the mess produced by cnc routing. You could even put bellows on to cover the gaps above and below the X axis extrusion.

- good stiffness at short cutting heights - where the work is close to the x axis.

Problems:

- worse stiffness when cutter is far from the x axis through torquing the x axis extrusion. Could it be lessened by an angle iron screwed to the x axis extrusion or a second box extrusion?

- motor has to lift itself and the weight of the ballscrew linear actuator and the spindle and do several kilos of cutting… I see many ballscrew kits with 50kg lifting capability for a z load. I think all of this is maybe 15kg estimate?? So seems do-able?

- would the shapeoko’s delrin v-wheels be up to dealing with this sort of weight hanging off them? (I guess so? the HDZ is not very different, and apparently that works)

- not really a problem, but the z direction would be reversed. clockwise rotation would bring the spindle up… That’s a simple grbl fix I think? Also the z limit switch would need to point down to stop the spindle side frame as it comes up.

What do you think? Are the physics of a ballscrew linear actuator holding a spindle pretty similar whichever way round you have it? The rub comes if you do a long extension like I drew… But that’s down to the torquing that happens due to the cutter load hanging off an increasingly long lever… Stiffen the X axis extrusion or take increasingly light cuts as you move down could solve this?

I drew this using a shapeoko model I found on the sketchup 3dwarehouse. Mine is an XXL and has the new z plate (although that would be irrelevant in this scenario) The XXL would be the worst model for handling the torquing issue…

Again, your thoughts?

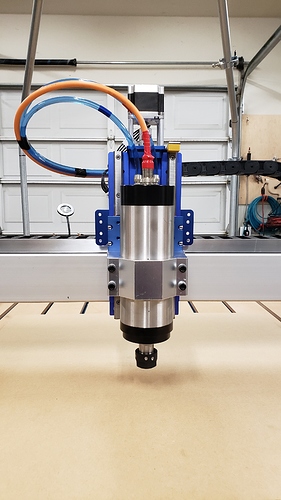

I’m running the HDZ was one of the earlier adopters of it. I also run a 2.2kw water cooled spindle. All I can say is it was worth every penny I paid. Had issues with the design of the stock z-axis have no issues with the HDZ. It’s well designed and well implimented. Luke has also sourced heavier derlin v

wheels for the upgrade, and also has heavier eccentric nuts that put the stock nuts to shame. Switching directions for Z travel is just a simple machine code edit. Along with TPI adjustment. The Z-axis will not drop on shutdown, nor slip like the origional.Do yourself a favor and just buy one now and save you all the trouble a 2.2kw spindle on a stock z-axis will give you.

Wow, strong endorsement, probably well deserved. Being a relative newbie and not running a business, I have not hit the limits of the stock setup yet, since I’m not milling metal, I cannot cost justify the upgrade at this point, I will wait a bit longer!  I may however consider the precision Z plate for my current setup.

I may however consider the precision Z plate for my current setup.

Not to undermine Luke but I wonder if Carbide is considering some of these to build a Shapeoko 4. It would be interesting to start a thread on what should be in the design of a Shapeoko 4.

That would be nice to start planning out the next reiteration of ShapeOko. The issue is though the ShapeOko is and was always designed to be an affordable entry machine. And they have done wonders, they have gone beyond entry level as a whole for an entry level price. But as you try to get more accuracy and regidity the price goes up exponentially. Most people agree the z-axis is ShapeOko Achilles heel and thats where people like Luke come it with aftermarket modes to make a good product better. I doubt ShapeOko would incorporate something like the HDZ because of cost, but who knows maybe an upgrade to the people who really want it. I am very happy with his design myself and am working on the belts next (steel reinforced) to make it more solid. Then on from there. The beauty of ShapeOko is you can make anything you want out of it.

This topic was automatically closed 2 days after the last reply. New replies are no longer allowed.