I’m not exactly pleased with how difficult you have made the machine to figure out. Why no instructions of any kind? The tutorial section is not only severly lacking in information but has misinformation as the Carbide 3d software is different than what I have and not only looks crappy on my computer but is missing the move tool screen. Why only 1 download for 1 of the tutorials? Really??? FYI: The people most interested in buying these aren’t going to know what to do or where to start, just like me most are not professional cnc people. If we were I doubt we would need or want one at home. I so frustrated right now I feel like I just wasted a lot of money. None of the tool bit packaging info; 0,LOC,FL,OAL,…makes any sense to me nor do they match w/ MeshCam and your store web page info for the bits as wellis wrong- The “go to” web page for the bits on the bit boxes are dead web pages. I don’t get it. Please explain. Why aren’t ALL your tool dimensions pre loaded in MeshCam and not just only 2 ball bits that come w/it? Do you want me to break lots of tool bits so I have to order more? Well I don’t want and can’t afford to! I also don’t want to have to dig and sift through tons of blog posts for hours just to not find the important information I need. I didn’t buy this expensive machine to become a blogger and I shouldn’t just be told to go to a really lame Wiki page for a Shapeoko to try and figure it out either. I need some simple info like ;What does this button do in our software and Here is a graph with pics of different end mill bits with their dimensions and values to enter and where to do so. I think the machine is well made and nice to look at but…you guys are killing me. Please take a little responsability and put some, important type, must know info on a real web page that is easy to find and access. Thanks

Can’t help you w/ MeshCAM, I don’t use it — there are some links and tutorials and notes on it here: http://www.shapeoko.com/wiki/index.php/Commercial_Software#3D_CAM — there’s also been some discussion of it here (ISTR that at least one was about entering tools) and GRZ Software does have its own forum setup.

You may find it a good idea to review some basic terminology if you’re not familiar w/ CNC and CAM concepts: http://www.shapeoko.com/wiki/index.php/Glossary

A couple of different workflows are documented on the wiki: http://www.shapeoko.com/wiki/index.php/Workflow and you might find the old Shapeoko 2 first job is helpful: http://shapeoko.github.io/Docs/firstjob.html or you may find it easier to start w/ Carbide Create rather than MeshCAM.

Most of the stuff is just acronyms which I think should be added to the wiki under the end mill page.

LOC: Length of Cut so basically how much of the end mill has a cutting area on it

FL or FOL: Flute Length - Length of flutes or grooves.

OAL: Over all length or how long the bit is in total from one end to the other.

below has more details… way more than you need.

Everyone snaps end mills at some point. I’ve lost 12 since June but mostly 1mm end mills and a few 1/8th in as well.

If you have other specific questions feel free to ask, everyone here is more than happy to help and Will is more than happy to copy past a link to the wiki

I agree that adding end mill info into the tool library is a pain in the ass… on every program not just meshcam.

What were you trying to make? Just curious.

After you learn this stuff once you should be good to go.

Added to the glossary, and to the endmills page: [spoiler]Shapeoko CNC Router, Rigid, Accurate, Reliable, and Affordable

You used my inelegant wording! Now I’m feeling overly self conscious.

At least their is a link back to this post so people can see the picture… as they say a picture is worth a 1000 words.

My apologies. If you wish to edit your post (or the wiki directly — just send a PM to wikiadmin on the Shapeoko forums for an account) we can make sure things get up-dated. It seemed concise / accurate enough that it would just become wordy/verbose if changed.

Maybe someone will edit / improve it at some point even if you don’t though.

@Valknutr

True, there is a lot to know, thats why CNC is a powerful tool and technology to learn.

Its impossible to learn everything at once, start with the tutorials and simple projects like these clamps:

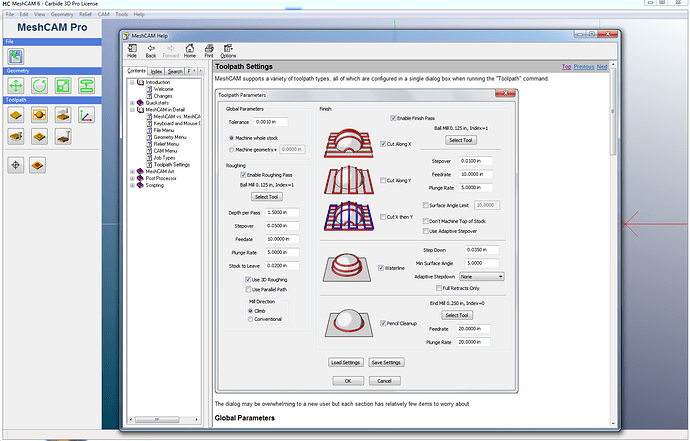

One resource that is built right into MeshCAM that gets overlooked is the HELP tab.

Heres the Nomad speeds and feeds chart for your reference:

http://carbide3d.com/nomad/feedandspeed/

-Apollo