Good evening. I was wondering if anyone could help me out. I am making a few flags for some folks and already cut the stars in the union. However, between the time I first cut the stars and today, the paint was scratched and needed to be redone. Of course, the stars and union paint are usually two different colors, so I repainted it with the blue background, thinking I would remask the union after it dried and place it back on the table to recut the stars and respray the stars.

In addition to scratching the paint, I also completed a Z-axis plate and spindle upgrade. I went from running a Makita trim router on a Z-Plus Z-axis plate to mounting an 80mm PwnCNC Spindle on the Shapeoko HDZ. So, to summarize, I first cut the Union Stars with the basic trim router on a Z-plus plate and am now trying to recut the stars after upgrading my machine.

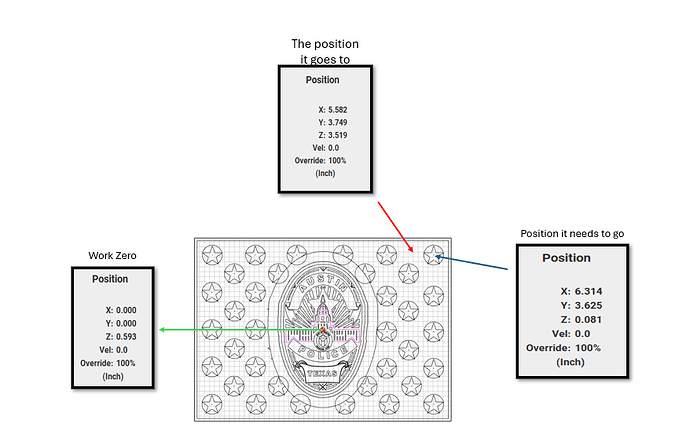

The trouble comes when I place the board on the table and try to run the toolpaths to recut the stars. I have done this a dozen times and never had an issue like this. For some reason, the machine will not move to the correct position when the toolpath is entered. I am using the original file with which the flag was cut; the only changes are the spindle and HDZ upgrade. I have attached a worksheet showing what is happening. I made circles around each star to find the centers and then created a new toolpath for centering using the Peck feature in the drill toolpath.

Still, the machine will not go to the center of any of the stars; it is always off. I have spent all day using the manual jog to measure each star from the center, and everything matches; the machine just will not go to them. If anyone has any helpful advice for me, please let me know. Thank you.

So after upgrading your machine hardware, did you run through the setup Wizard & select/upload the correct configuration parameters?

Is your project file setup set for the correct machine? I’m not sure this would change anything but worth checking.

Is your machine sounding/acting like it’s losing steps - stuttering/stopping/grinding randomly?

Changing up the hardware means the cables get pushed around - maybe the connectors are getting strained & then not providing reliable connections.

Are you loading the correct version of the project file in Carbide Motion?

Just some troubleshooting steps I would start with to figure out what’s going on.

If you MDI G0 G20 X6.314 Y3.625 Z0.1 Where does the machine go?

If you look in the G-code, where is that star being cut?

So, after upgrading, it took a little time because there weren’t any specific instructions addressing the exact steps to take when upgrading your machine, but I eventually returned to the initial setup instructions from when I first received the machine. Before initializing (although I had already initialized before returning to this step), I completed a new machine setup in CM and downloaded the new step codes for a Shapeoko Pro w/HDZ.

Once the new configuration was loaded, I went through the initialization steps and set the location for the bit setter. At this point, the machine appeared to be performing the same as it was before the upgrade. When placed in the home position, it returned to the back right corner and did not miss measuring the tool with the bit setter. In addition, when commanded to move to each of the nine Cardinal Points rapidly, it has been right on. I even carved a small test project, and everything went as planned. There were no issues with any of the cables being too tight, nor were there issues with the limit switches. Therefore, I had no reason to believe there would be any trouble recutting an old project.

As for the project I am trying to recut, I used the exact same c2d file used to cut it the first time and it was placed in the exact same X/Y spot on the table. I do not understand why I cannot get the machine to run the same toolpath as before.

As I said earlier, the measurements are the same when manually comparing the distances from the work zero to the center of each star by using Jog and then comparing that distance to the measurements in the c2d file. The only thing is that the machine appears to believe the workpiece is smaller than it is for whatever reason. I have not tried replacing a different piece yet to see if it will retrace a different toolpath, but I will try that today. As a last resort, I guess I could create a different file by rebuilding the layout and see if the machine would react accordingly. Short of that, I do not know what else I can do.

If the distance the machine moves has changed, this is probably because the belt tension is different.

For calibrating it see:

You could apply that principle to adjust the current steps/mm so as to match the movement by the previous setup.

That is quite strange. You may want to check the X/Y steps calibration in addition to the belt tension check.

You mention that you’ve verified via jogging that the distance the machine indicates it has moved to each star matches the project file. It this is true, then either the project toolpath is somehow bad or the motors are losing steps due to intermittent connections - I really can’t stress enough how random/perplexing/subtle intermittent connections to the motors can be(due to personal experience). However, you did successfully run a test carve - run it more than once to check the reliability.

Only other thought I had was to do with Imperial vs Metric settings & if the settings for that in CM & CC are the same. As far as I know it really shouldn’t cause an issue, but I’ve never actually tested that. And to maybe re-generate your star toolpath’s & save as a different file name.

One option to maybe save your existing carve, though tedious, would be to create a project file with just the star object carving - centered on a center-zero point. Then manually zero the CNC to each star to re-carve them one by one.

The curious part is that op has checked the position of the stars already carved via jogging & compared to the project file - and they match.

So then where is the error coming from when running the original carving toolpaths?

Quite the puzzle…

Thanks, everyone, for the help. Turns out my trouble was with the belt tensions. All three belts were tensioned very differently. Someone suggested I check the belt tension, and that got me to research, and I ended up using the TWANG method since I do not have a luggage scale. To make a long story short, it took about half a day for me to figure out what I was doing, but I was finally able to get the stepper motors in sync, and I even found that the carriage could use a little squaring, which was a very annoying challenge.

The only thing left is to figure out a reliable way of flattening my work table. I tried it once, but it does not appear to have been effective, as it still has high and low spots. I believe that has a lot to do with my inability to duplicate toolpaths after removing the workpiece from the table and replacing it.

I also need to learn how to adjust the GRBL settings in CM so it doesn’t take ten seconds from when I hit the “Start Job” button until the spindle carriage moves forward from wherever its current position is to the front right corner so a new tool can be loaded and measured by the bit setter.

For flattening the first time you probably want to flatten, tram and then flatten again.

This topic was automatically closed after 30 days. New replies are no longer allowed.