Here’s how I did mine:

Note, I am assuming the Shapeoko feets are adjusted in accordance with the manual.

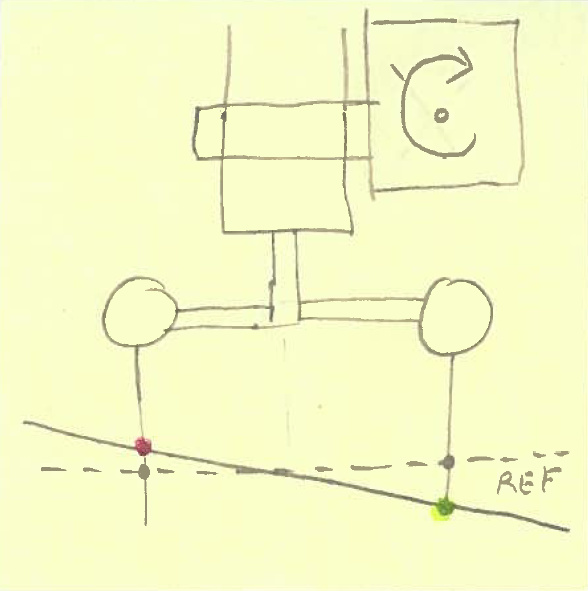

- Established a Datum or reference plane using a piece of glass plate.

The larger the size, the better the resolution and accuracy. Also, the thicker the glass plate, the less chance of it sagging in the middle.

-

Place glass plate on the Shapeoko’s platform.

-

Raised the glass plate using 3 objects of equal height. I will refer to these 3 objects as “feet”.

-

Position 2 of the feet so that they are running parallel to the “X” axsis.

-

Position the 3rd feet so that it forms the shape of an equilateral  triangle.

triangle.

-

With a sharpie marker, make 3 dots on the glass plate forming an “L” shape and the base of the “L” shape running parallel to the “X” axsis.

The further the dots are, the better the resolution / accuracy in leveling the glass plate.

The dots will be used for repeatability when positioning the dial indicator.

-

Mount a dial indicator to the “Z” axsis.

-

Using the software controls, move the gantry and align the dial indicator to the dot running parallel to the “X” axsis. This will be the reference measurement.

-

Lower the “Z” axis and preload the dial indicator. The dial indicator should be on the dot.

-

Rotate the dial indicator’s bezel to zero.

-

Do Not move the “Z” axsis.

-

Check for repeatability by moving the Gantry away from the dot and then back on the dot. The dial indicator should be on zero. If not, adjust the bezel to zero and repeat.

-

Move the gantry to the next dot in the “X” axsis ONLY.

-

Note the dial indicators reading.

-

If the dial indicator reading is low add shims so that the dial indicator will read zero.

NOTE: If the dial indicator reads high, swiched the reference dot and rezero the dial indicator.

-

Move the gantry in the “X” axis ONLY back to the reference dot. Verify that the dial indicator reads zero. If not, rezero the dial indicator and repeat process, steps 12 to 16.

-

The 2 dots running parallel to the “X” axsis should be leveled.

-

With the dial indicator zeroed to the reference dot, move the gantry to the 3rd dot and note the dial indicator reading.

-

Shimmed as necessary so that the 3rd dot reads the same as the reference dot and the 2nd dot.

-

If all 3 dots read the same, zero, the glass plate is leveled and will be the datum plane for performing the tramming verification and/or adjustment.

Tramming Verification / Adjustments.

NOTE: The calibrated magnetic height gauge that came with the tramming tool will NOT be use.

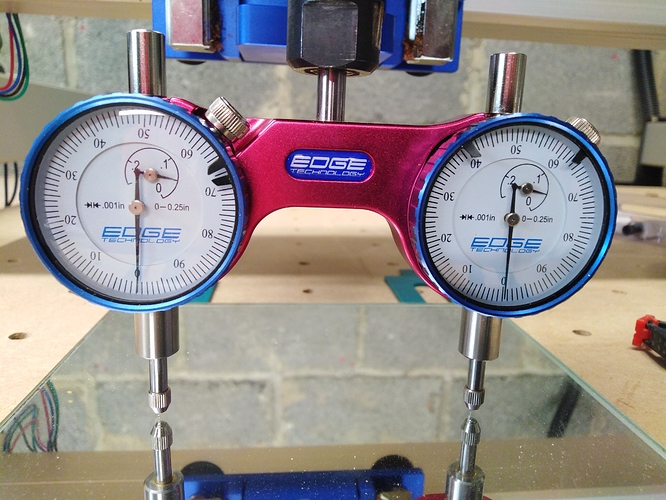

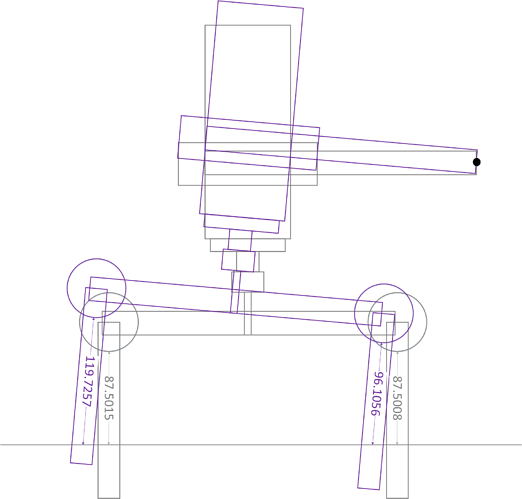

a) Mount your tramming tool to your router.

b) Move the Gantry over the center of the glass plate.

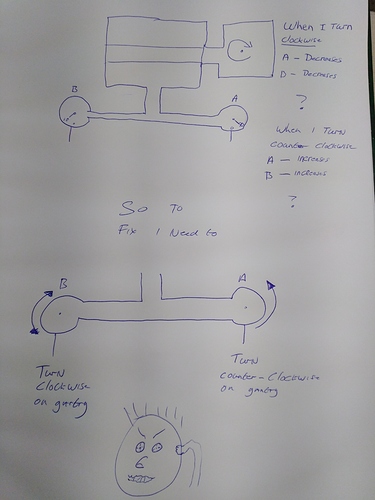

c) Position the tramming tool so that both dial indicators are running parallel to the “X” axsis.

d) With a sharpie marker, place a dot on the glass plate such that one of the tramming dial indicators dspindle will masks the dot. This dot will be the reference point.

e) Lower the “Z” axis to preload the tramming dial indicator.

f) Zero out the dial indicator by rotating the bezel.

g) Rotate the tramming tool away from the reference dot and the back. Check for repeatability. Rezero if necessary.

h) Rotate the tramming tool 180 degrees.

i) Place the tramming tool’s 2nd dial indicator’s spindle so that it masks the reference dot.

j) Zero the dial indicator by rotating the bezel.

k) Check for repeatability per step g. Adjust the bezel as necessary.

l) Both tramming tool’s dial indicators are now zeroed and referenced to the same plane.

m) Rotate the tramming tool 360 degrees. Both dial indicators should be reading zero or closed to.

n) If both dial indicators are not reading within the required specifications than the gantry or router mount must be adjusted.

o) When making the adjustments, position the tramming tool so that both dial indicators are running parallel to that plane.

Always check for repeatability and verify that the glass plate is still leveled.

triangle.

triangle.